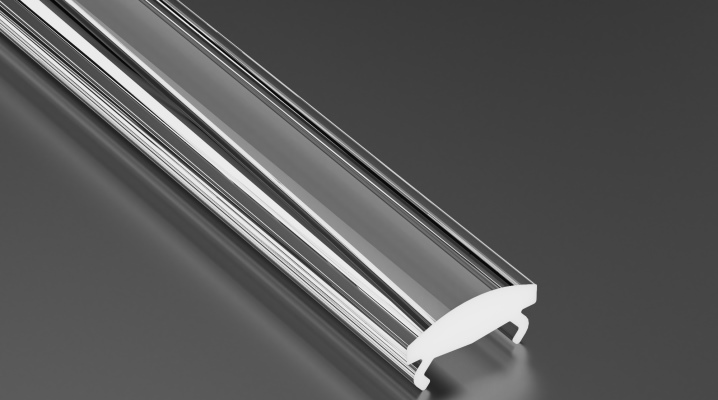

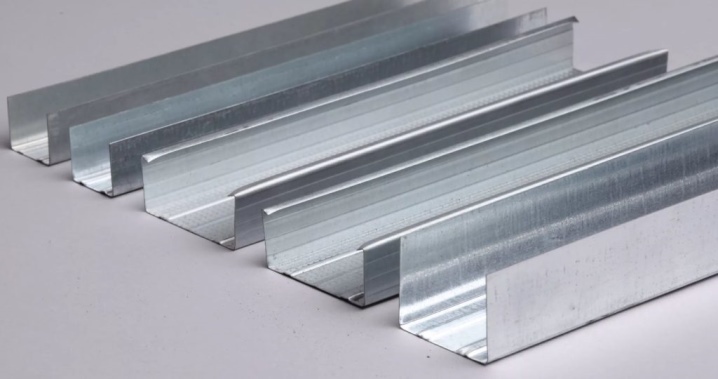

Aluminum profile cutting

Cutting metal profiles has long ceased to be an impossible task. Today there are many tools and devices with which you can easily cope with such workflows. In this article, we will learn how the cutting of an aluminum profile can be realized.

Compact equipment overview

Cutting aluminum profiles can be carried out with various devices. For example, in the preparation of such material for the further installation of drywall, it is the compact devices that are the most convenient and practical to use. Many craftsmen prefer to use such equipment, since it does not take up much space, is easily transported from place to place, and you do not have to make a lot of extra effort to work with it.

Let's consider the main features of the most popular compact devices with which you can cut an aluminum profile.

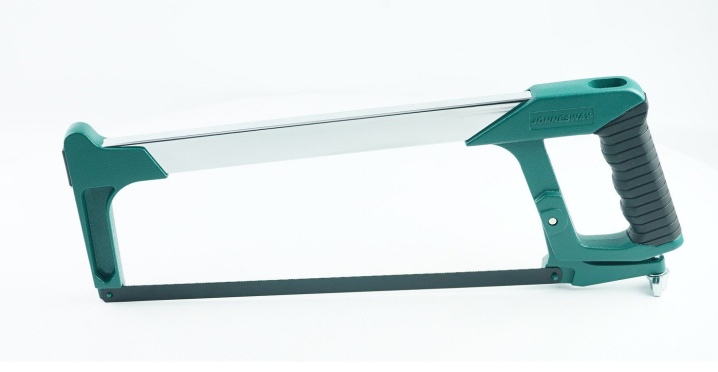

Hacksaws

Not in all cases there is a possibility of using electrical equipment for the purpose of cutting a metal profile. These are tools like a miter saw. For this reason, craftsmen often have to make do with simpler tools. The most popular and practical tool is a hacksaw for metal. With this device it will be possible to cut sheet material and a profile of moderate thickness. They always start cutting from the edge, and then act on the back side. Finish off on the sides.

A hacksaw for metal has a lot of positive qualities that make it convenient and practical.

- Such a tool is characterized by a very light weight. Thanks to this, during the cutting of the aluminum profile, the hands of the master do not get tired and do not start to hurt.

- Working with the tool in question is extremely simple. Everyone is capable of understanding the principle of operation of a hacksaw for metal.

- The device itself is inexpensive. Hacksaws for metal are sold in many stores. In most of them, this tool has a more than democratic price tag.

- The efficiency of a hacksaw can be compared to that of an electric jigsaw. Of course, working with a hand tool takes more time and effort for the master.

Of the minuses, the following is worth noting.

- It takes a lot of time to carry out work on cutting metal.

- In the course of cutting the aluminum profile, it can undergo deformation.

- When working with a hacksaw, the craftsman will need to maintain the aluminum profile all the time. However, the clarity of the work will not be guaranteed.

Scissors

Cutting metal parts is even easier if there are special scissors in the toolbox. The process is extremely simple: it is enough to first mark the aluminum profile, and then cut it along the outlined lines.

Shears for metalwork also have their positive qualities. Let's get acquainted with them.

- With scissors, metal is cut faster than using a hacksaw.

- Scissors for metal are inexpensive and sold in many stores, which indicates their availability.

- If the tool is of high quality, and the master acts competently, then you can get very good and accurate results.

Metal scissors are not without certain disadvantages.

- At the moment of movement over the edges of the workpiece, there is a high risk of leaving the applied marking line. Because of this, the workpiece itself or its bending deteriorates noticeably.

- Before cutting the aluminum profile, you will need to practice a little on "rough" blanks, which are not a pity to spoil. You will have to learn a little about cutting metal perfectly correctly and accurately, and this is an extra time investment.

Grinders

An excellent tool with very good functionality. With the help of a grinder, an aluminum profile can be cut as simply and quickly as possible. Of course for cutting, you will need to use not grinding, but cutting wheels. You will need to choose a tooling that has a small thickness parameter. This is the only way to minimize material losses.

When working with a grinder, the master will definitely need to use protective equipment in order to protect the eyes and skin from sparks.

Such a popular tool as the grinder has a number of significant advantages.

- With the help of a grinder, the master can make a very accurate, correct cut. At the same time, it will take very little time.

- Such equipment is relatively inexpensive and is produced by many well-known brands. In stores you can find a grinder of both budget and very expensive categories.

- Working with the tool in question does not require much effort from the wizard.

- Special equipment designed for working with aluminum profiles is designed for a long service life. She should not require a quick replacement.

Against the background of attractive qualities, one should not forget about the shortcomings that the grinder has.

- During the work, there is a risk of burning the aluminum billet.

- It is not so easy to make an absolutely even and correct cut if the master does not have the appropriate skills and experience in working with a grinder.

- To achieve high accuracy of cutting aluminum, it is advisable to fix the grinder on a special base-stand. This part is sold separately and is not always found in stores. If there is no such item, some craftsmen use a vice.

Jigsaws

To cut an aluminum profile, it is quite possible to use an electric jigsaw. It is a very handy and compact tool that many DIYers have in stock.

Before starting directly to work, it makes sense to make sure that the appropriate file for metal parts is installed in the device.... Blades for wood can be easily cut and aluminum, but the quality of the cut will not be the highest. The cutting process itself begins from the rear, after which the side edges are cut in turn.

Let's find out what strengths the jigsaws demonstrate.

- Electrical equipment greatly simplifies any work, especially when compared to manual devices.

- The quality of a cut made with a jigsaw can be almost perfect. There will be no burrs, bevels and other possible defects.

- The work will not take much time.

- There is a possibility of repeated use, if you choose the right file correctly.

- A jigsaw will cost much less than other similar devices for cutting aluminum profiles.

The tool in question does not have a large number of serious shortcomings. However, the master will need to make sure that the workpiece is as firmly and reliably fixed as possible. Otherwise, in the course of cutting, it can "lead" under the influence of a jigsaw.

What else can you cut?

Correct and accurate cutting of aluminum profiles can be realized not only with compact tools. For such work, special laser, milling or plasma installations are also perfect. It is very convenient to work with them and you can get good results. Saws are no less relevant.Below we will consider what features such functional equipment has.

Plasma, laser, milling machines

Plasma and laser cutting machines are the ideal solution if you want to cut metal as quickly and efficiently as possible. However, such options are not suitable for home use. Plasma cutter and laser machine belongs to the category of professional equipment. This technique can be found in various large enterprises.

Such equipment has the following positive characteristics:

- cutting aluminum with a laser or plasma machine will take only a couple of minutes;

- the master only needs to set up professional equipment, and all other work is done by the machine;

- the quality of the cut with such equipment will be the highest.

Of the minuses, it can be noted:

- the high cost of such high-quality equipment;

- it is not possible to use such equipment at home or in a garage;

- laser and plasma cutting machines make a lot of noise during operation.

Separately, it is worth talking about modern milling installations.... Such equipment must be correctly adjusted by the operator to work with aluminum. This requirement is due to the high softness and ductility of this material. Also, it is no less important to set small indicators of revolutions of milling equipment (from 5000 to 9000 per minute). You will first need to drop a little kerosene on the area where the cut will be made.

The supply of the workpiece here should be as accurate as possible, otherwise you can spoil the cutter of the technique. The pros and cons of a milling machine are similar to those of a laser and a plasma cutter, but the quality of the processing of parts is slightly less qualitative.

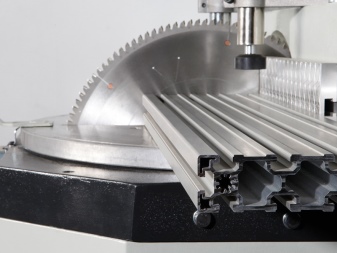

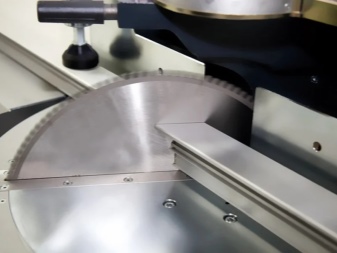

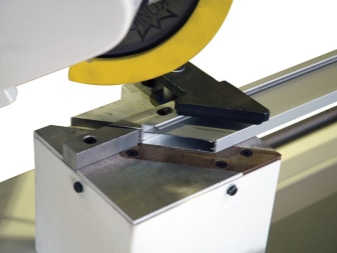

Saws

Often, different types of saws are used for cutting metal. Find out about the characteristics of the most popular options.

- Circular. Analogue of hand tools, but with more power. With a circular saw, you can make longitudinal, transverse and oblique cuts (for example, at an angle of 45 or 90 degrees). Modern technology is able to eliminate overheating by switching off at the right time. It is a durable, reliable and practical tool, maneuverable, and reduces the time spent on work.

- Disk... Many circular saw models are capable of cutting very large workpieces. The tool itself may have very small dimensions. The circular saw can be used for corner cuts. The accuracy of the work here turns out to be as high as possible. True, a saw, in the design of which there is a special disk, will cost a tidy sum.

- Miter cut. Much like a circular saw. Can cut lengthwise, straight, inclined. A firm fixation of the workpiece in special clamps is provided. The miter saw can cut long aluminum profiles.

How to cut correctly?

Let's consider step by step how to correctly and evenly cut an aluminum profile.

- First, you need to mark the metal workpiece. To do this, you can use a ruler or tape measure. Place marks with a marker.

- A perpendicular mark must be applied to the product. It is along this line that the side planes will be trimmed.

- Then folds are made along the marking line. Last but not least, a bend cut is made.

- If we are talking about cutting a rack-mount profile, then the master must remember that he has auxiliary stiffeners. Sometimes they come out slightly uneven. You can trim them with scissors. Slats with a length of up to 1 m can be cut by weight, but longer parts will require fixing in supports or a vice.

- To prepare lintels or small structures, the profile should be cut at an angle of 45 degrees. First, you need to saw off the slats of the required length, after which you should mark the angle of the notch and complete the procedure by cutting it off.

Profile cutting must be carried out strictly according to the technology... When working with any tool, it is very important not to forget about the observance of safety rules. It is better to stock up on all the necessary personal protective equipment, and carry out the work themselves carefully, without rushing.

How to properly cut an aluminum profile can be seen in the video below.

The comment was sent successfully.