How is a washing machine motor replaced and repaired?

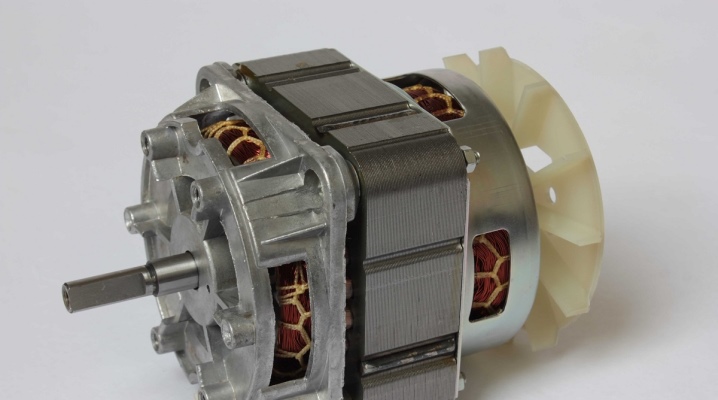

The engine is the only source of torque, mechanical energy, without which your washing machine cannot handle washing your laundry. It is subject to wear and tear - like the rest of the moving parts of the automatic washing machine (AGR). A greater load falls on it than on the drum, taking into account the mechanical losses due to friction of the contacting surfaces.

Causes of malfunctions

There are six reasons why the washing machine does not deliver the required mechanical power.

- Wear of the bearing part of the shaft. A very rare case when it is the rotating axle that is damaged, it is the most durable part of the supporting structure, including the stator and rotor plates.

- Bearings broken or not lubricated. Ball bearings fail more often - much more often when they forget to lubricate them at least once every six months or a year with lithol, solid oil or graphite grease. Excessive friction brakes the motor shaft.

- Burnout windings. Short-circuited loops are known to emit large induction currents in alternating magnetic fields of the rotor and stator. The resistance of one turn is so small - and incommensurable, not matched with the large current - that a significant amount of heat is released, destroying the winding. This is true for rotors and stators of motors, transformers, chokes and electromagnets - wherever a core coil is used.

Overheating of the engine is a sure sign of short-circuited loops: the temperatures at this point are such that adjacent loops can also burn out, and the motor is unstable.

- Reduction of supply voltage... Situations are widespread when, instead of 220 volts, the voltage becomes equal to 127. This is a rarity - but at least once every few years, power plants and substations can produce reduced voltages, according to which the final voltage will be set at exactly 127 V. For household appliances, such a voltage is not dangerous. This does not threaten washing machines - the turnover will almost halve. A collector motor, for example, does not really care how many hertz frequencies are in an outlet - 25 or 50.

- Brushes worn out. Collector motors are designed in such a way that the rotor windings are connected in series with the stator winding through graphite brushes. Engine operation for 1000 hours or more wears out the brushes. Frequent heating of the motor from prolonged operation at maximum speed contributes to the wear of the brushes even more. New, unfinished brushes that generate excessive sparking also cause the motor to malfunction.

- Drum overload with laundry... Do not load more pounds of laundry than indicated in the instructions.

There are five reasons why the machine does not wash the laundry (the drum is stationary).

- Loss of electrical contact. Winding breakage occurs due to critical shocks and vibration during engine operation. The winding is also damaged during storage and use in aggressive environments, for example, in rooms where vapors of strong mineral acids are present. The fault of the breakage can also be the burning of short-circuited turns, mechanical damage from foreign objects caught in the motor, etc.

- The accidental supply of 380V line-to-line voltage is guaranteed to destroy all electrical engineering and electronics in the house.... The MCA is also not designed for this kind of stress. Use a high-power regulator for which the input voltage can fluctuate from 100 to 500 V (such a device is extremely difficult to find).

- The belt has fallen off or is damaged. Some CMAs use a belt drive from the motor shaft to the drum.

- Thermal protection is triggered regardless of the cause of the motor overheating: overvoltage, turn-to-turn circuit, long-term many-hour washing of tens of kilograms of laundry (in batches, one after another), grease consumption, etc. The thermistor is triggered when the temperature of the stator plates exceeds 90 degrees of heat. When the thermistor is “fired off”, the supply current to the motor stops until it cools down below 80 degrees - only after that the thermistor “snaps off” back.

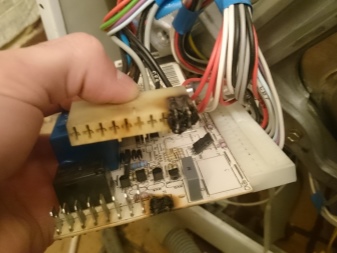

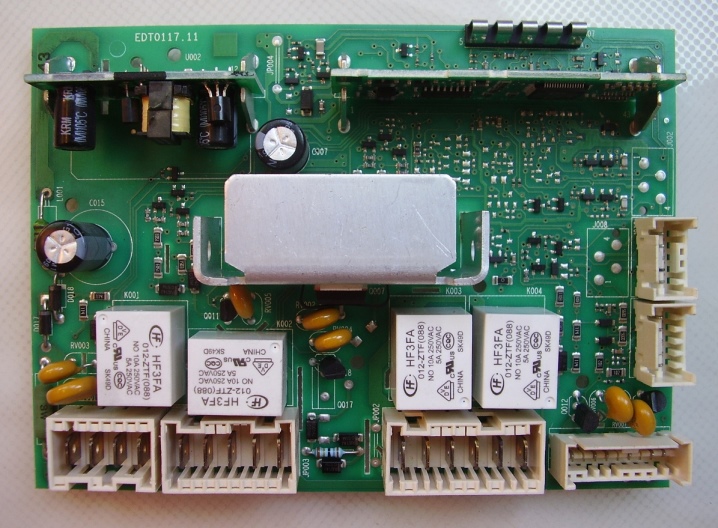

- Breakage of the ECU (electronic control unit). This is a control board, divided into electronic and electromechanical (power circuits with switching relays) parts. If the program or electronic parts of the board (processor, RAM, ROM, flash memory) fail, control commands will not be transmitted to the power circuits. The wear and tear of the contacts of the relays themselves (for example, one of them that turn on the engine) after millions of operations also cause the engine and the entire mechanics to fail.

Having initially determined what is the reason, it is easy to fix the SMA with your own hands.

Breakage detection

The problem from the engine manifests itself in different ways.

- Sparks from below - the brushes are worn out, the terminals connecting the power cable to the motor are burnt out.

- Crackling - there is an interturn short circuit in the windings, the motor components are covered with conductive graphite dust.

- Whistles - the increased whistle level comes from the inverter driving the overloaded inverter motor.

- Shoots - breakdown of the motor winding or heating element on the case. Most often this happens when the machine heats up the water, and the engine is also started (it works during the periods set by the software). The breakdown is checked by a tester - in ohmmeter mode.

- Drum jerky - the belt drive is broken, the belt is stretched. The jerky operation of the engine is also observed with worn-out brushes or fuzzy operation of the inverter, unreliable power supply, no clear circuit when the control relays on the board are turned on, oxidized terminals on the wires.

The first step is to check the engine itself.

Common motor repair

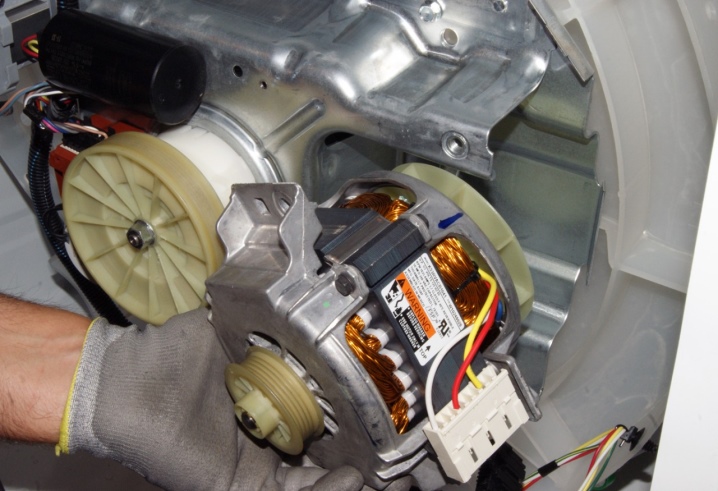

To get to the engine, do the following:

- disconnect the power by removing the plug from the socket, move the machine away from the wall;

- turn off the water supply from the water supply and disconnect the inlet and drain hoses;

- remove the rear wall of the machine (in some cases it is necessary to dismantle the tank and move it to the side, since the engine is under it).

Check the operation of individual parts of the motor.

Brushes

Unscrew the locking screws on the sides of the motor and remove the brushes. If they are almost completely worn out, replace them with exactly the same ones. The ideal option is to buy similar ones, this is a consumable for the motor. The resource of the brushes is up to 15,000 hours.

Bearings

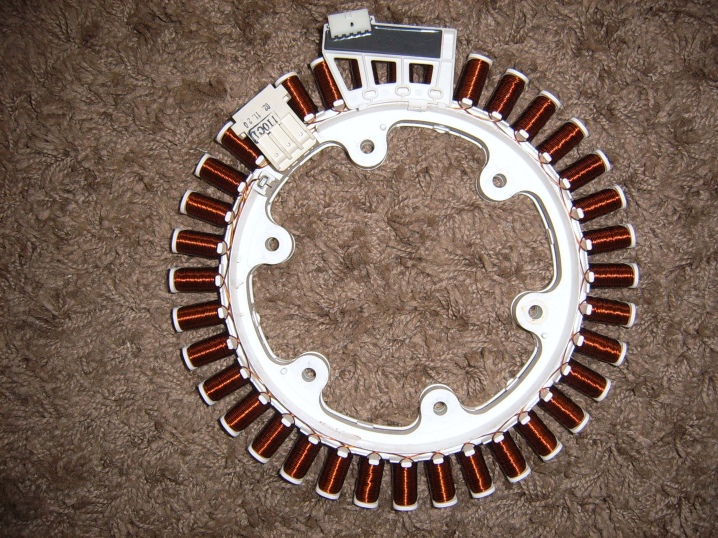

It may be necessary to disassemble the stator (it is usually divided into two halves) or the rotor can be removed from one end. At the ends of the rotor (or in the stator itself) bearings are fixed. Replace them with exactly the same ones. They can be found on any market. Their interchangeability is possible - from similar engines.

Wires

It is easier to change both wires and terminals than other parts. Any power wires with a cross section of up to 1.5 mm2 will do. Terminals and cables can be found at your home improvement store. New terminals with wires are connected using soldered joints. If the wire is broken, the connection is restored by soldering, and this place is insulated.

Wires with damaged insulation must be replaced.

Lamels

Lamel - copper plate on the current-carrying "belt" of the rotor. The number of lamellas can reach 20. Accordingly, the number of windings is 10, since the beginning and end of the winding are connected using paired lamellas and are in contact with the brushes.Graphite, grinding off the brushes during operation, can “blacken” the lamellas. Clean them with fine sandpaper. If the lamella has peeled off, only replacing the entire rotor will help: in collector motors, the windings are filled with compound or epoxy glue, and it is impossible to solder the lamella to the end of the winding.

Stator

Burnout of stator windings requires stator replacement. Often, the stator winding is also filled with compound or "epoxy", and such a motor cannot be repaired. If the service center did not find a working stator from a used engine, in which the rotor burned out or worn out, then the engine is not repairable and is replaced entirely. On "unpolished" motors, the stator is rewound on its own - only a coil of a new enamel wire of the required section is needed.

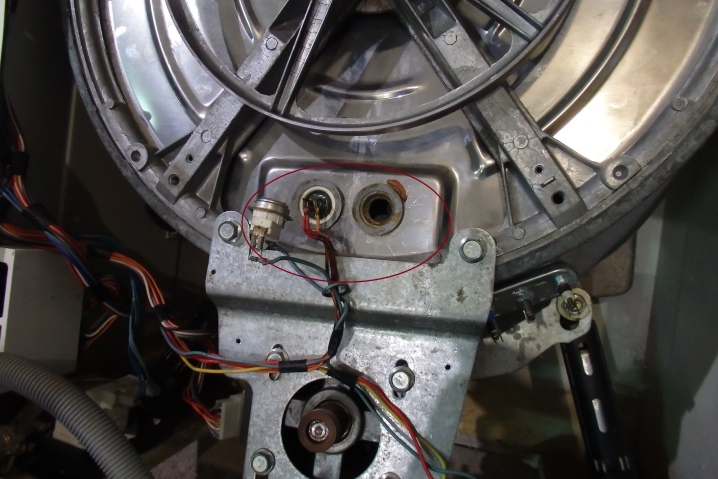

Thermal fuse

Replacing the thermistor is easy. It is a quick release element. Most often it is located on the stator plates. The suspicion of a thermistor breakdown arises when the overheated motor has cooled down, there is contact between the ECU and the engine, and the motor does not start.

Try to turn on the motor "short-circuited" - bypass the thermistor using a difavtomat (if the motor takes 220 volts) or a jumper. After installing the jumper, restart the CMA program from the point of stopping.

Replacing the washing machine motor

If the motor is still faulty - and not repairable, then do the following:

- de-energize the machine;

- remove the belt (or direct drive wheel) from the motor;

- specify in the instructions where the fasteners with which the motor is fixed are located, remove these bolts;

- remove the contacts from the motor terminals;

- lift the engine and remove it;

- install exactly the same motor in its place;

- connect and assemble everything in reverse order.

Reconnect the water supply and outlet, open the water tap. Try to start the car. The laundry will be washed normally in accordance with the parameters of the selected program. If the functionality of the SMA is restored, then put it in its original place after the end of the wash.

See below for how to replace brushes and motor bearings.

The comment was sent successfully.