Do-it-yourself Electrolux washing machine repair

A washing machine is a device that allows you to clean clothes from dirt and dust using special detergents. It is considered one of the most demanded types of technology, and no family can do without it. Washing machines of the Electrolux brands are considered one of the most reliable and efficient on the market. But they, like any technique, can break down or work incorrectly. In this article, we will try to figure out what the main breakdowns of such washing machines can be and how to repair them yourself.

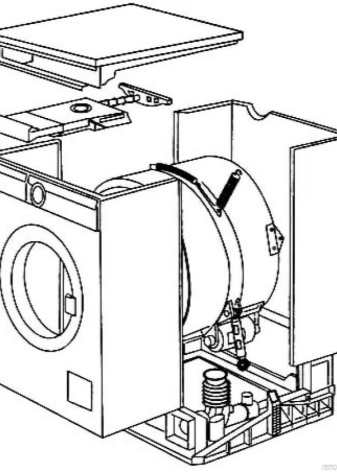

Design features of Electrolux washing machines

If we talk about the design features of Electrolux washing machines, it should be said that in general, they are no different from washing machines from other manufacturers... This brand from Sweden does not only manufacture front-loading machines. Its lineup includes more than a dozen models with top loading. In order to better know the features of a particular model of a washing machine, which is to be disassembled, cleaned or repaired, it will be necessary to study the diagram. It is located in the instructions for a specific washing machine model.

Usually, there are no serious differences in terms of design between the models of this manufacturer. Although if we compare models with horizontal and vertical loading, then there will be differences. For example, the loading of linen into a vertical washing machine is carried out from above, and above, on a special panel, there is a control panel. In the same time in front-loading models, the laundry will be loaded from the front of the machine.

At the same time, there will be no differences in the principle of work here. The only difference will be in the location of certain elements - drum, heating element and so on.

Causes of breakdowns

In most cases, the washing machine itself signals that its operation is incorrect or there is some kind of serviceability. It does this by displaying certain codes, each of which means a particular malfunction. However, not all problems and malfunctions can be indicated using symbolic commands on the display. A number of them can be easily identified by their external features.

- The RCD is constantly triggered, and the machine does not start. In this case, the reasons for this may be a short circuit of the heating element or the motor, or there is a breakdown on the case.

- The washing machine makes a lot of noise during use... Most likely, something is stuck between the tub and drum, or the laundry has strayed to one side. Bearing wear can be another cause.

- The device does not heat the water... This may be caused by a problem with the heating element, temperature sensor, control triac.

- Inability to close the hatch door. Usually the reason for this is either the wear of the tongue, or the breakage of the handle, or the device that is responsible for blocking the hatch.

- The device simply does not turn on. The reason for this may be a breakdown of the socket, start button, control unit.

- The washing machine does not draw water. You need to clean the filter, intake system or hose. The intake valve may be out of order.

- Technique does not drain water... This is usually the result of a blockage in the drain pipe, hose or pump.Another reason for this may be the combustion of the pump windings.

- The drum does not spin and the machine does not wring out the laundry during washing. In this case, either the motor is faulty, or the motor brushes are worn out, or the drive belt has fallen off the pulley.

If we talk about models of washing machines with vertical loading, then their main "disease" is the wear of the drum supports. Their replacement is similar in complexity to installing a bearing, and you cannot do without disassembling the device. In this case, the following breakdowns are also frequent:

- wiping the hatch cuffthat causes water to enter the electronic lock, because of which it breaks;

- top cover corrosion due to the specifics of water supply through the top, which requires a complete change of the top cover.

In general, as you can see, there are plenty of reasons for various types of breakdowns due to the rather complicated design of the washing machine.

Diagnostics

Without special equipment, a number of elements of the washing machine are simply impossible to check. For example, an electrical part or a control unit. If we are talking about mechanical problems with one or another element of the machine, then you still need to disassemble the device, then look for the problem and decide whether you can fix it yourself, whether you can repair a specific element or need replacement and other spare parts.

After all, even if we talk about the problems from the list that is presented above, then you can see that several different cases can be the cause of a particular breakdown.

And even the master can not always immediately determine the cause of the malfunction of the washing machine. Therefore, the diagnostic issue will be individual in each case and depend on the rules for operating the washing machine.

Disassembling the case

Whatever the malfunction, almost always it will be necessary to disassemble the washing machine in order to get to its insides and already find out what the problem is. Let's try to figure out how to do this. The disassembly process starts with the fact that the device must first be disconnected from the outlet. Now we unscrew the inlet hose, having previously shut off the water supply to the washing machine. Now you need to remove the top cover. It is held in place by 2 screws located on the rear panel. They should be unscrewed.

Now you need to make an effort and pull it towards yourself. After that, unscrew a couple of bolts on the top panel on one side. They are responsible for securing the back wall.

It is important to say here that most Electrolux models are made in such a way that they can be disassembled in two halves. There are hidden screws in the side wall, which are located in the middle. They are hidden by stubs. And to get access to them, you need to remove the plugs. Unscrew both screws. Now you need to unscrew a couple of screws in place of the back wall. This pair of bolts is not available on all models of the Swedish brand washing machines.

You need to release the plastic holder, which is secured with a pair of latches... They must be given away with a screwdriver and the holder must be lifted up. Here you need to point out an important point - some models of cars have a holder consisting of 2 elements, which are fixed together with a bolt.

To dismantle the holder, unscrew it and snap off the latches. Now we completely pull out the back wall of the device.

Thus, we get access to the following elements:

- engine;

- tank;

- water pump;

- pump;

- belt;

- drain hose;

- Heating element;

- shock absorber.

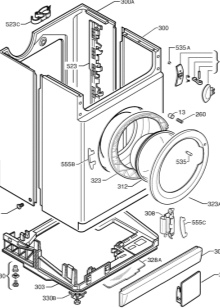

Of course, this is the most common instruction for parsing a washing machine from a Swedish manufacturer. If we talk about the disassembly of the brand's vertical washing machines, then it is carried out as follows:

- Slot-type screwdriver required first pry off the control panel, then pull it up and move it back;

- slightly tilt and take pictures, exactly how the wires are connected, after which we unscrew the fasteners and dismantle the board;

- remove the filler valveafter removing the hoses from the clamps and disconnecting the wires;

- screw in the fasteners and dismantle the panels on the sides;

- now we see the fasteners, by unscrewing which, we can remove the bottom cover and access the most important parts of the washing machine.

Typical malfunctions and how to fix them

One of the most common problems that an Electrolux brand washing machine may have is that it simply does not turn on. The first reason for this might be lack of voltage in the network. It also happens that knocks out a circuit breaker due to a short circuit... It happens that this is a consequence of the operation of the residual current device. This usually happens due to a breakdown on the device's case. The reason may be defective outlet or surge protector... To check all versions, a tester should be used to measure the resistance values at the contacts of the power button and the wire. The algorithm of actions will be as follows:

- take out the powder compartment;

- unscrew the mount that holds the dashboard, and then dismantle it;

- we take out the plastic holders that hold the dashboard;

- we find the contacts of the button and measure the resistance.

If the problem is in the contacts, then they should be stripped and soldered, after which the device is assembled. If no problem is found, then the matter is in the network cable malfunction.... Then you need to remove the back cover, and then remove the protection gasket, which is located at the base of the cord. Now you need to check the reliability of the connection of the wires of the network cable and the filter contacts. If they are fixed well, then we disconnect the wire and check it with a multimeter for breakdown. If it is, then it needs to be replaced with another one. After that, the washing machine is assembled and its functionality is checked.

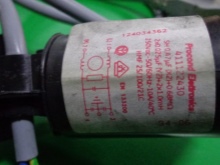

Another common problem is that the device does not draw water even though there is water in the tap. There may be 2 reasons for this:

- clogging of the filter in the inlet hose;

- failure of the filler valve.

The filter can be cleaned with your own hands, but more often it is simply replaced. The same applies to the filler valve, which is usually changed in the event of a malfunction. If for some reason there is no water drain, then there can also be only 2 reasons for this malfunction:

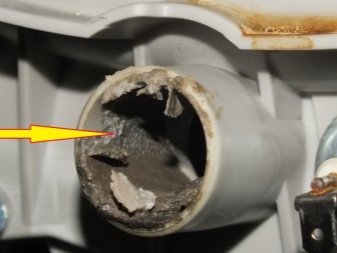

- blockage in the drain hose;

- the drain pump does not work.

To replace the drain pump, you can use the instruction manual that comes with the kit, but the cleaning of the drain hose will be performed according to the following algorithm:

- we drain the water that remains in the tank through the emergency hose located at the bottom next to the drain filter;

- disconnect the drain hose from the device;

- now you need to rinse or blow it well;

- put the drain hose back;

- we collect water into the machine and check the drain.

If you are faced with the fact that the Electrolux machine skips rinsing or spinning the laundry, then this means that the control board is defective. Self-repair of this part is simply impossible, unless you are a specialist in the field of electronics.

If it happens that the detergent powder remains in the tray after washing, then the problem is in the tray valve, which is responsible for the short-term injection of water when it is typed. During operation, the valve becomes clogged or may simply break. If it breaks down, then it can only be replaced, and if it is clogged, you can try to rinse it with a strong stream of hot water.

If it turns out that the water in the washing machine tank does not heat up, then this indicates a problem with the heating element. To begin with, you should very carefully inspect the integrity of all cables and wires that go to the heating element from the power supply. After that, you should use a multimeter and ring the temperature sensor of the heating element. You should also check the contacts of the heating element itself. If a malfunction of the heating element or its temperature sensor is detected, then they should be replaced. If a wire break was found, then you need to fix it, make insulation and re-solder the contacts.

In rare cases, it happens that the water in the tank does not heat up due to a malfunction of the control board. As noted above, only a specialist can repair it.

Another common category of Electrolux washing machine malfunctions is door problems... During washing, it should be closed as tightly as possible. For this reason, it usually has 2 types of locks: electronic and mechanical. The latter is made in the form of a tongue, which, when closed, enters a special hole, due to which it is fixed. The second type of lock provides for blocking at an electronic level. If it occurs, a click will be heard.

If there is a problem with the door, then first you need to inspect the door handle for deformations. If it is found that the tongue does not reach the hole, then the loops are faulty. This can be corrected by tightening the hinge bolts.

If it is necessary to diagnose the electronic lock, then you should inspect its contacts for burning and damage. This requires:

- bend the rubber that acts as a seal;

- pry the clamp with a screwdriver, which must then be removed;

- unscrew a couple of bolts;

- stick your hand inside and pull out the blocker;

- if a problem is detected, then you should disconnect the contacts;

- replace the part and reassemble everything in reverse order.

Another common problem is that the washing machine makes a lot of noise during operation. Moreover, this noise can manifest itself as crackling, creaking, and so on. There may be several reasons for this.

- Looseness of the drum pulley attachment, causing crackling and choppy whistles. In this case, the fasteners should be unscrewed and put on a sealant, but the pulley needs to be replaced, because it cannot be repaired.

- A foreign object is caught between the washing tub and the drum. In this case, it is required to remove the covers of the washing machine, and if there is such an object, remove it from the device.

- If the machine makes a hum during operation, then most likely the bearings are worn out. First, under the influence of moisture, the oil seals wear out, which seals the shaft, after which the bearings themselves rust and break. Usually, they immediately replace both those and other elements.

Shock absorbers and springs can also be a possible cause of noise, which can cause noise during operation.

Because of them, the reservoir is displaced and subsequently tilted, as a result of which, when the machine is operating, it beats against its walls. The same reaction will occur if the counterweight breaks down. All of these elements must be replaced if faults are found.

Repair Tips

Here are some interesting repair tips, the observance of which can help not only when repairing a washing machine, but also in extending its operation. To maximize the life of your Electrolux washing machine, you should take care of her as carefully as possible. For example, a rubber seal should be wiped after each wash process, as hair, animal dander and water accumulate there. If you do not do this, the drum will smell unpleasant.

Another important point - the pump filter needs to be cleaned regularly, after all, there are often small objects in it, which can cause poor drainage.

Scale should not be allowed to form, because it has a bad effect on the operation of the device.... To prevent its appearance, you need to use special powders. In addition, powder formulations should be used specifically for automatic washing machines.

If we talk about home renovation, it will not be superfluous to lubricate mechanical parts so that they work as long and efficiently as possible. In addition, you should understand what exactly you are doing and be guided by the device diagram. Otherwise, you can consult a specialist from the nearest service center.

Repair of Electrolux washing machines, see below.

The comment was sent successfully.