Choosing racks for a warehouse

Rational placement of goods in warehouses is ensured through the use of special rack systems. From the material in this article, you will learn what they are, what they are, how they are placed. In addition, we will highlight the main nuances of their choice.

Peculiarities

Warehouse shelving systems are huge organizers with the most rational placement of various objects. They differ in design, roominess, and carrying capacity.

Depending on this, they have different dimensions, storage methods. Solve the problem of lack of space... They can be located from floor to ceiling. In some cases, they resemble complex two- and three-story structures with flights of stairs and walkways.

They are mainly made of durable metal, taking into account the frame of a particular storage facility. Wood, polycarbonate and other polymers are also used in production.

They are collapsible, equipped with various elements and fasteners. Refers to industrial storage systems. They can be transported and reinstalled and are the key equipment required for a complete warehouse.

Compared to conventional shelving furniture, they are more durable and practical. They are traditional and with reinforced shelves. Provide free access to every unit of the product. They differ in purpose.

They have the ability to adapt to the individual characteristics of the warehouse. They have an adjustable shelf height, provide for the installation or removal of sections unnecessary for storage.

Accommodation requirements

To organize an optimal environment and efficient storage performance, you should arrange equipment according to safety rules. This is necessary to speed up loading and unloading activities, storage of huge consignments.

According to GOST standards, the recommended distance between metal structures should be at least 80 cm. For more convenient travel, passage between systems during planning, a greater distance is projected.

The placement of shelving takes into account not only one-way, but also two-way traffic. The main transport passage is located opposite the entrance. Its value corresponds to double the width of the loader and a distance of 90 cm.

The minimum parameters are related to the size of the warehouse gate. When placing shelves, a number of nuances are taken into account.

- When storing goods in stacks, the passage between the rows and the fence should be at least 80 cm.

- The width of the viewing corridor between every ten stacks should not be less than 100 cm.The width of the corridor opposite the doorway is equal to its width with the minimum allowable value of 100 cm.

- Large warehouses are equipped with structures with central corridors. Their width should not be less than 250 cm.

- When using racking systems with pull-out shelves, the width of the corridors is increased depending on the type of installation of structures.

- If the warehouse is equipped with a one-way system, the passage is increased by 0.5 shelf parameters. If the racks are double-sided, the aisle is widened to the full width of the shelf.

Technical standards allow the location of the longitudinal side of the module with a clearance of 0.2 m to the fence. There are exceptions for special shipments. For example, it is prohibited to place them near heating radiators.

They are mounted at a distance of 80-100 cm from the wall ceiling. Evacuation openings are arranged along the rack end. It is strictly forbidden to locate the cargo in the openings between the stacks and movement corridors.

According to GOST R 55525-2013, front-loaded structures can have wide and narrow aisles... Wide aisles should allow the loader to turn up to 90 degrees. Their width is 2.5-3.7 m. Narrow aisles vary from one and a half to 1.9 m.

Shelving systems are designed to optimize the workspace. Placement should take into account compliance with fire safety standards.

In addition, planning must take into account the permissible load capacity of the cells, the integrity and reliability of the structures.

Views

Based on the type of construction, there are several types of production shelving systems. They are classic, high-rise, elevator, modular, carousel.

By the type of storage, they are divided into varieties with cells, roll-out and pull-out platforms, storage boxes. Each type of shelving system, whether it is universal, reinforced or mechanized shelving, has its own characteristics.

Shelving

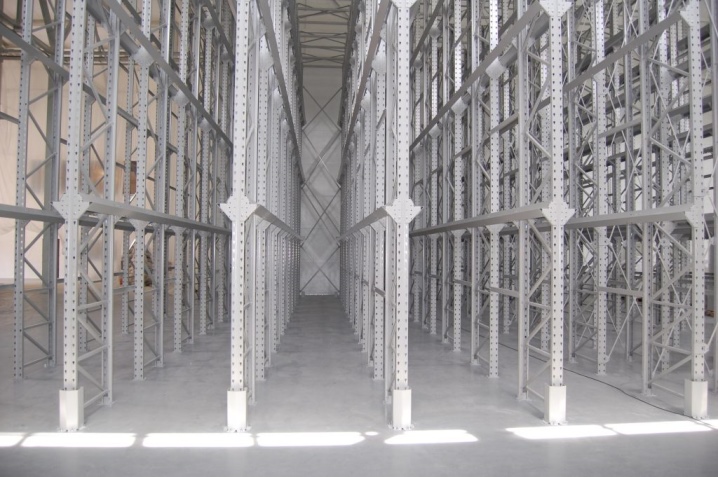

Shelf-type racks are classified as collapsible products. They are produced on the basis of side frames, load beams, shelves and other parts. They are designed for storing heavy loads. Therefore, especially durable materials are used in their production.

Storage systems with shelves are easy to use. They do not require special equipment for loading and unloading, there is free access to the stored goods. It is assumed that the load is placed in a horizontal plane one above the other.

Suitable for placing loads of different sizes, weights, types. Refers to a standard storage system. Manufactured from galvanized steel, iron components, plywood and chipboard. They have a wide range of applications.

They differ in the level of carrying capacity. There are classic (with a load of up to 300 kg), medium-duty (with a maximum permissible weight per structure of 450 kg), cargo. Freight versions can withstand a shelf load of up to 900 kg and up to 1300 kg per frame.

Printed

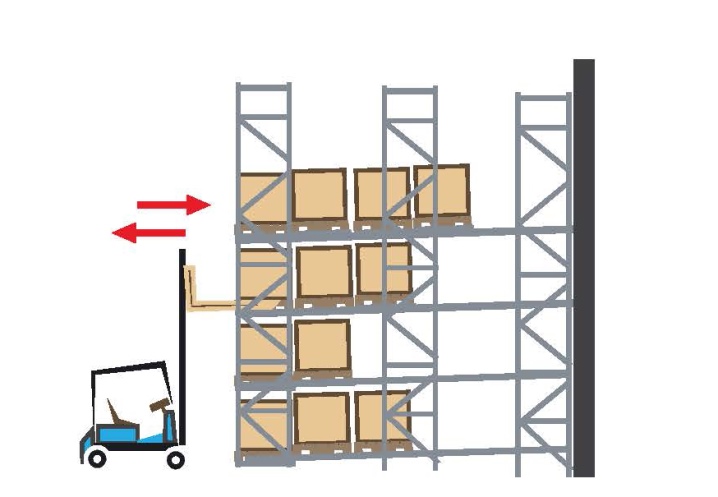

Printed industrial racks are divided into 2 types: walk-through and deep. They differ in the type of loading of goods for warehousing. Depth systems are used when loading and unloading from one side.

Wall structures do not have aisles. They are designed to store homogeneous products in pallets. Used for placement in large warehouses. Compared to other systems, these racks have the highest load-bearing capacity.

They are rigid metal structures made of vertical frames connected by horizontal beam rows and guides with cells, on which pallets with goods are attached. They are placed in horizontal rows using a loader.

At the same time, they are compact, due to which it is possible to optimize the storage space by reducing the aisles between the rows. Provide for the regulation of the distance between the cross beams. Suitable for block storage of fragile goods.

Frontal

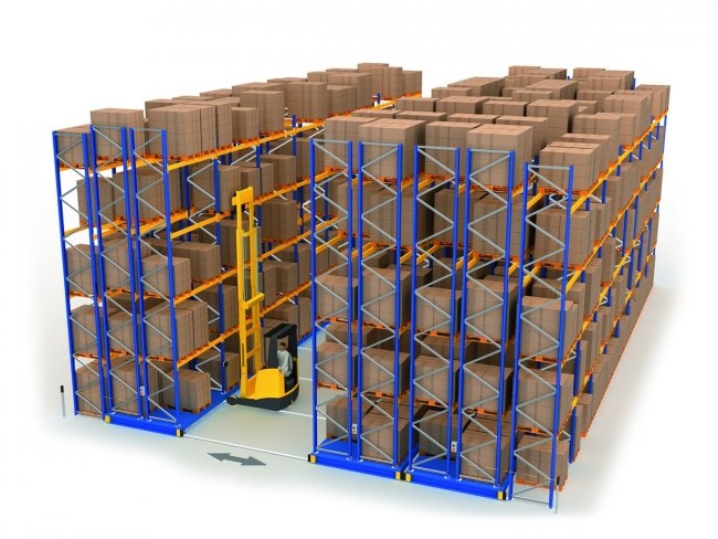

Front-end production racks have become widespread due to the ability to store goods on pallets. These systems are convenient and versatile, they can be used to store goods of the same type or combined type.

The size, weight and type of cargo can be anything. They are distinguished by efficient operation of the working space. Convenient when performing inventory of goods.

Combined with an addressable control system. Equipped with a wide range of auxiliary components (load frames, beams, side guards, leveling plates). Thus, it is possible to design different types of front shelving systems.

This allows you to assemble structures with a different number of tiers, designed for a specific load capacity. There are narrow and wide aisles, as well as double depths.

In varieties of the latter type, the number of storage spaces increases. Served by a loader with telescopic forks. Used in warehouses of automotive, industrial chemical, pharmaceutical companies.

Gravitational

Racks with a gravitational type of design differ from their stuffed counterparts by the presence of shelves with a roller mechanism and their slope downward from the side of the loader... The slope of the end-to-end systems is designed in such a way that pallets and boxes move along the structure due to their weight.

This technological equipment has a complex system of braking mechanisms and stoppers... This affects their cost, which is about 5 times higher than the price of universal front-type models.

Gravitational structures are not very common, despite the many advantages.... Depending on the characteristics of the system, it may involve the lateral movement of pallets. In these racks, the number of tracks and the length of conveyors can vary on one or more levels.

At the same time, the stored cargo can move to the loader as quickly as possible. Simultaneous unloading of several racks is also allowed.

Mobile

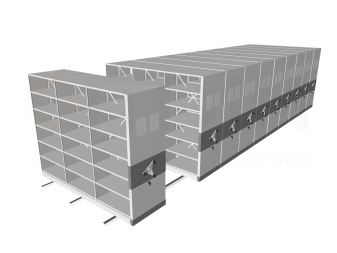

Mobile shelving structures are compact and significantly save storage space without compromising the convenience of loading and unloading. They are equipped with rails, side panels, main and auxiliary frames, housings, stops and mechanical drive handles.

Regardless of the workload, each rack can be easily moved tightly to the other. This is done quickly along the guide rails.

The systems are convenient for the ability to adapt to any load. They have different types of shelf fixation (bolts and clips). The designs provide for changing the height of the shelves without the use of special tools.

These racks have manual control and maximum safety, provided by locking mechanisms, as well as locks that close access to particularly important goods.

Mobile racks are distinguished by more rational use of warehouse space in comparison with stationary counterparts. they provide for adaptation in the form of docking of several sections for storing long-sized objects.

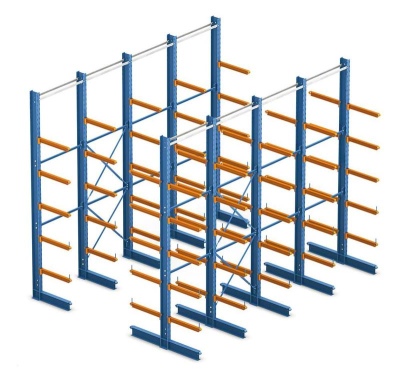

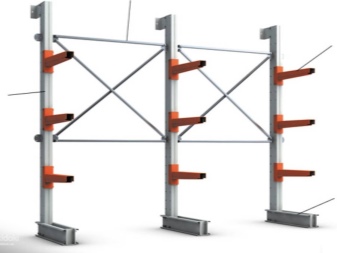

Console

Varieties of the console type differ from other systems in the absence of shelves and frames for loading pallets. They have vertical profiles and horizontal racks on which bulky cargo is stored (lumber, pipes, beams, cabinet furniture parts, rolled metal products).

Based on the specifics of the cargo, the storage system can be equipped with additional elements. The most common of these are wheel restraints, which are necessary to prevent the pipes from moving spontaneously.

The cantilever systems are serviced by forklifts with telescopic forks. The structures have narrow corridors. They are long, they are one-sided and two-sided. Variants of the second type have a larger capacity.

They are distinguished by ease of installation, the presence of limiters, they save the cost of arranging a warehouse... Depending on the type of cargo, they differ in size; even car bodies can be placed in them. In addition to consoles, such systems have vertical profiles.

Mezzanine

Multi-tiered warehouse storage systems are made for storing large volumes of goods with the possibility of simple combination of shelf and pallet type of elements on one structure.

A mandatory difference from other varieties is the presence of stairs. These can be two-tier, three-tier structures with areas for passage and passage between the rows with the stored goods.

They are characterized by the ease of transporting goods to the upper tiers by means of a conveyor system. They have an automated storage type, high processing speed. Goods placed at a height of 2-3 meters are served without the use of loading and unloading mechanisms.

The type of construction is hinged, free-standing, combined.

In the production of racks of this type, wood, metal welded mesh from reinforcement, perforated metal sheets are used.

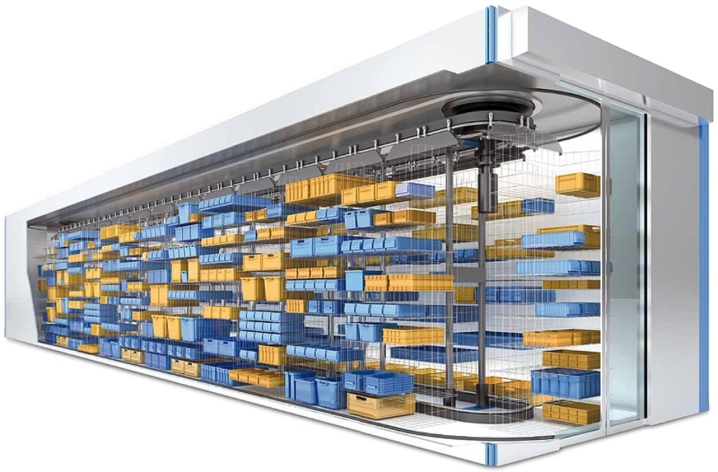

Carousel

Carousel (elevator) racks are classified as electronically controlled horizontal automated racking systems. They resemble continuous lifts with a product-to-person principle.

Used in warehouses with goods that require frequent unloading. They are distinguished by their small dimensions, which is why they are used as equipment for small storage facilities. They have a high storage density and the highest possible capacity.

Flexible systems are equipped with multifunctional shelves with dimensions adapted to the parameters of the stored cargo. They have an electric motor and roller chains moving along a closed path.

They have multilevel protection and ensure complete safety of the cargo. Provides emergency control, automatic chain tensioning, easy running, protective panels, separation of load-bearing elements in height.

Dimensions (edit)

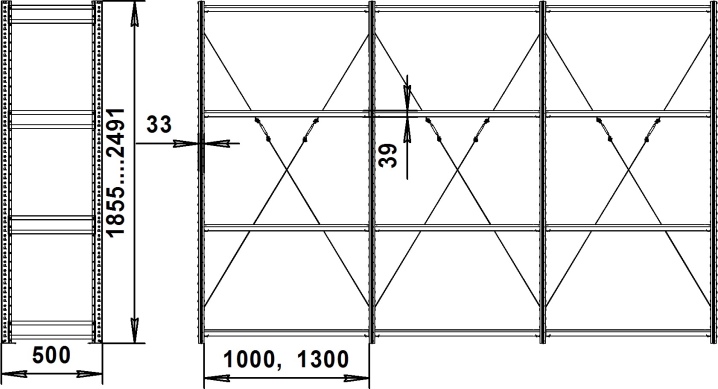

The dimensions of the shelving systems depend on various factors (type of construction, size of the warehouse, type of stored cargo). Based on this, they are standard, large and multi-tiered.

For example, gravity structures can be up to 30 m in length and up to 8 m in width. Dimensional limits are also determined by the needs of a particular company. In addition to the volume, the area is limited by the requirements for placement.

Large factories produce products with a height reaching 50 m. Medium varieties can have a height of 10-14 m, a length of 1.8-2.7 to 3.6-5 m and more. In this case, the step of adjusting the beams is half a meter, the load on the pallet can reach up to 1200 kg.

Manufacturers

Modern shelving systems of various types for warehouses are produced by many leading factories in Russia, Germany and other countries.

- "ASKomplekt" is engaged in the production of galvanized and stainless steel metal systems. Produces varieties based on stationary and mobile designs. Provides equipment for government organizations and commercial structures. It is engaged in the manufacture of high quality standard systems and structures to order at affordable prices.

- Stelkon supplies a wide range of industrial shelving systems to the domestic market. The assortment of the brand includes varieties of the automated type with radio shuttles, self-supporting, high-rise, mezzanine structures, products of the console, frontal, rammed, medium-load, gravity type. The Russian company provides clients with a range of services from the design of rack systems to their production, installation and service.

- LLC "Yarus" is engaged in the production of archival-type racks for equipping small rooms. In addition, the brand manufactures mobile heavy structures for storing heavy goods. The manufacturer's mobile systems save storage space without compromising the freedom of access to stored items. The structures are designed taking into account the rational use of each meter of the warehouse.

- Aveto Is a company with its own production facilities, one of the leaders in its segment. Works actively in all regions of Russia. Manufactures pallet, rammed, frontal, gravity, shelf, metal mezzanine racking systems for warehouses.Delivers deep pallet and box racks to the market. Designs and installs structures in accordance with international standards. Founder of the National Association of Shelving Manufacturers and Suppliers.

- Storemaster Is a German manufacturer of storage racks for metal rolls weighing up to 15,000 kg. It produces warehouse equipment for metal warehouses, metalworking industries, products for the storage of long goods up to 12 m in length and with a maximum permissible weight load of 6 tons per shelf. The range includes many types of systems with replaceable cassettes, drawers (including electric ones with a height of up to 2 m), lattice cassettes for metal residues, platforms for single sheets.

How to choose?

When choosing a rack for a warehouse, a number of criteria are taken into account. The key one is the construction of a warehouse for storing a specific product. Based on its dimensions, a racking system project is created.

Initially, an arrangement project is prepared, taking into account the characteristics of the foundation, the thermal insulation of the walls, the temperature inside the room, as well as other factors. Then they are determined with the placement of communications.

After that, the placement is planned. This issue includes the calculation of the width and length of the corridors, the ability to drive the forklift, the available warehouse equipment.

Pay attention to the filling of the structure, its convenience for the service personnel, the presence of software filling. They take into account the adaptation of the system for the storage of a particular product, taking into account the maximum possible weight and size.

The type of rack is determined based on your own preference. Before ordering, you need to pay attention to all the little things. For this, a plan is drawn up with the location of the shelving system, its characteristics and all other nuances are indicated.

This will visually assess the ease of access and maintenance. The heavier the load, the more massive and larger the structure should be... If you need an option for placing goods of the same type, order deep racks.

For storage of combined loads, it is worth ordering a system with shelves or pallets. Not the least criterion is packaging. Different types of racks are needed for pallets, boxes, barrels.

Among other factors, the method of loading and unloading, the conditions of the warehouse, the shelf life of the stored goods are taken into account. For perishable goods, frontal systems are needed.

The comment was sent successfully.