All about shelving

Knowing everything about shelving is a must for every warehouse organizer. Metal prefabricated warehouse racks with shelves, hanging models for warehouses have both disadvantages and advantages. Be sure to also understand the areas of application of such property.

Advantages and disadvantages

Shelf racks are a structure that can be easily assembled from single parts. You can flexibly diversify its length and the number of sections. Such designs are great in any room. The method of attaching the shelves to the uprights is mainly determined by the magnitude of the resulting loads.

Shelving racks are demanding on the characteristics of the flooring - and this circumstance is their only tangible disadvantage.

Their undoubted advantages will be:

-

ease of adaptation to specific tasks;

-

the ability to form large lines while saving on racks;

-

correction of dimensions along all three axes by changing the deck and traverses;

-

optional addition with wheels;

-

high mechanical strength;

-

ease of installation and disassembly;

-

relatively affordable price;

-

the ability to accommodate the most diverse goods and cargo, including oversized;

-

no need for loading and unloading equipment.

Views

The difference is mostly related to which shelves are used in the construction of the rack. Archival models are designed not only for storing documents, as one might think. They hold other small loads and even office equipment. The archival shelf rack has universal characteristics.

You can easily change the location of individual parts, collecting both the simplest lines and complex "fronts". The assembly procedure does not cause any problems.

Screwing the shelves to the racks in collapsible structures of this kind takes place with the help of bolts. It is not necessary to count on large sizes. However, the functionality and portability will definitely be at a decent level. Some models can be equipped with side and rear restraints. Often, equipment is provided with holders for folders and books.

Basic properties:

-

suitability for various premises;

-

ease of assembly;

-

high stability;

-

ease of transportation;

-

ease of design changes;

-

sharp edges in galvanized versions;

-

installation strictly on a flat floor.

Household prefabricated shelving racks are designed for a wide range of different things. But despite the name, they are not only suitable for private use. Many of these designs are still used for commercial purposes. Such a rack does not take up too much space. The maximum load on one tier can reach 120 kg.

Mezzanine type shelves are multilevel "storey" structures. They can also store a variety of things. Even piece bulk goods. Special mezzanine parts are added to the structure. Such storage systems give excellent results in small rooms with high ceilings. For work, you can safely use technology, and access to stored accessories is simplified.

Other important properties:

-

easy installation;

-

increased storage area;

-

the possibility of alteration exactly for the cargo that is required;

-

the possibility of using not only for storage, but also for picking goods.

When space is limited, hinged (wall) racks work very well. With their help, you can store quite different items.However, it is worth considering the load limit, which is less than the traditional floor-standing versions.

Important: multilevel storage systems are also attached to the walls if their height exceeds 3 m. Only under this condition a normal level of reliability is ensured.

At the same time, alas:

-

the width of the aisles is limited;

-

components are difficult to repair;

-

loaders can easily damage parts even with a slight impact;

-

maintenance requirements are very high.

It should be noted that the racks can be fastened not only with bolts, but also with hooks. This allows for greater rigidity, however, at the same time, the design becomes more complex. In fact, such storage systems can be considered reinforced compared to purely bolted ones, because they are designed for a much higher load capacity. Pallet deep storage is not just multi-level, but also spatial, working on the principle of "one in, one out." The structure is formed by:

-

frames of vertical type;

-

guiding elements;

-

upper beams.

The main load falls on the guide parts. The pallet rack is good if you have to wrap large batches of similar goods in a narrow range. Also an important condition for their use is low circulation intensity. That is, already for a store with brisk trade, this is hardly suitable. Getting to individual pallets is not easy, however, the density of the accumulation of things is increased. The reason is simple - the number of passages and passages between individual structures is reduced, and loaders must enter the "channels" and fill the layers there from the back to the front, and unload in the reverse order.

Pallet depth systems allow the use of a wide variety of pallet types. They are also attractive for equipping chambers with microclimate control. But the complexity in handling them does not allow recommending such warehouse equipment if there is no way to attract experienced people. Pallet front models are a good alternative. They differ in that they allow easier access to single sections and positions.

The front shelf is assembled and disassembled without much difficulty. You can group such elements into a different number of lines. The length is limited, in fact, only by the size of the premises and the needs of the owners. The use of various types of cargo vehicles is allowed, with rare exceptions. Other important properties:

-

suitability for accumulation of both pallet and different types of cargo;

-

the ability to set aside the lower tier for the selection of goods, manipulation with them;

-

reduction in the efficiency of using the same area in comparison with a deep-pallet system;

-

poor storage density;

-

high probability of crossing the unloaded and loaded goods, which slows down the work and even potentially creates critical situations.

Much higher efficiency when using pallet and shelving racks. They can store bulky cargo. The shelves themselves are made of metal, less often of chipboard (which immediately reduces the carrying capacity). Such solutions are acceptable not only in warehouses. The trade also readily selects them.

Options:

-

ease of execution;

-

ease of access to certain goods;

-

very high price;

-

flexible definition of the number of storage levels.

Materials (edit)

Traditionally, racks are made, of course, from metal elements. And this is understandable - they are reliable, durable and fire-resistant. Sometimes it is even necessary to make a special effort so that something breaks or breaks down. But the metal is heavy, and its black grades are also prone to rust. In everyday practice, even in reputable organizations, wooden storage systems are sometimes used.

True, they have to be protected with special impregnations from fire, water, biological decomposition. Metal and wood are close in that just careful processing is enough to give them a neat look. It is more difficult to work with plastics. They are less processed and more often damaged even with careful handling. Therefore, plastic and glass are used only as additions to metal and wood (with rare exceptions, and each such exception is worked out, calculated by engineers separately).

Applications

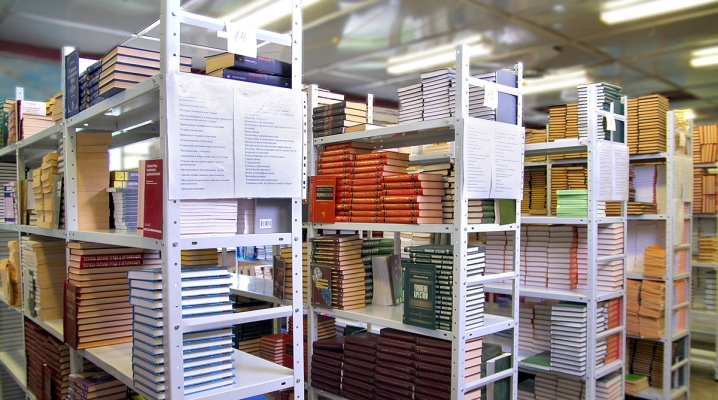

Shelving racks are associated with warehouse equipment. But they are designed to store various items, not only in warehouse conditions in the proper sense of the word. Suffice it to say that such items were used in ancient libraries. Modern librarians also use these storage media on a daily basis and will continue to use them until the widespread use of paper editions ceases. The traditional Russian approach, since at least the 19th century, implies that each enterprise and organization supply themselves with shelves - which is why for a very long time such equipment was produced only to the maximum tailored to the needs of specific industries.

But the situation has changed significantly in recent decades: warehouses are also forced to change. Now they are being built according to the principles of maximum flexibility and quick rebuilding from one task to another at the lowest cost. Classic shelving racks can usually withstand a load of no more than 250 kg. Anything that is more powerful, either belongs to a different type, or is made by special order. But even with this limitation, the racks can be used to equip:

-

libraries;

-

archives;

-

office rooms;

-

accounting department;

-

private dwellings (for dishes, clothes, books).

The comment was sent successfully.