All About Mezzanine Racks

Shelves are in great demand, they have a lot of advantages, besides, they are presented in different variations. Mezzanine structures are installed in factories and warehouses, at home, when there is not enough space for storing various things. Thanks to such a device, you can easily and competently organize the work of the warehouse. This equipment is used in rooms with high ceilings. Shelves can be in several versions, each of which has its own advantages and features. We bring to your attention the characteristics and list of advantages of warehouse equipment.

Peculiarities

Mezzanines are popular technological warehouse equipment that is used in large enterprises. The main advantages of the system are comfort, easy installation and mobility. This design can be quickly and conveniently assembled, saving space. Thus, you can increase the free area to store products and personal belongings.

It is safe to say that this type of shelving has become a real breakthrough in the field of warehouse management.

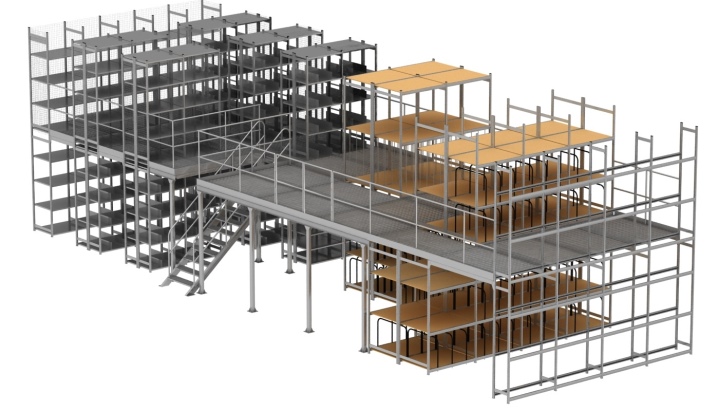

Any goods can be stored in them, and maintenance does not require much effort and cost. It should be noted that no special equipment is required for high mezzanines, which is an advantage. The structure is based on vertical columns with load-bearing beams.

For the manufacture of flooring, wood, metal reinforcing bars and sheets are used. Therefore, the product is durable, reliable and will serve for many years. From beams and decking, tiers are created that allow the equipment and employees used in the warehouse to move. The material for the manufacture is chosen carefully and seriously, since strength, quality and reliability of operation depend on it.

For the production of beams, various profile elements can be used, among which there are pipes, T-bars, etc. The role of the frame is played by the load-bearing components, they are connected with bolts. The main requirements for the structure are stability and rigidity. For movement, manufacturers make stairs with handrails to ensure comfortable operation. There are racks with freight elevators, thanks to which the handling of goods and the safety of goods are improved. Lifting mechanisms are both stationary and mobile.

As for the size of the shelves, structures are created with a height of at least 2-3 meters, and sometimes much more.

To prevent slipping, the steps are made of perforated metal sheet, which ensures good grip. One of the requirements for mezzanines is the presence of enclosing handrails, which can be equipped with gates in order to deliver cargo upstairs using elevators or lifting mechanisms.

Racks belong to the category of collapsible structures, which are characterized as technological equipment, therefore, for their installation, the presence of permits is not expected. As for the technical characteristics, we can say that they depend on the type of product, its dimensions, the load of each floor, etc. However, the height cannot be more than 15 m, and the bearing capacity cannot exceed 28 tons. The tiers must withstand at least 3 tons, and the maximum allowable weight per square meter is 1500 kg.The metal is treated with special compounds to provide protection against corrosion, since warehouse structures are often located in rooms where there can be dampness and low temperatures.

Mezzanines have a lot of advantages, thanks to such structures, you can efficiently use the warehouse space, increasing the volume of stored goods. In addition, racks can be installed not only for storing goods, but also to equip offices and staff rooms with them. Structures lend themselves to easy conversion, they can be adjusted to the weight and shape of the stored goods.

Shelves have a wide range of possibilities as they can be moved. It is easy to deliver cargo to the upper floors, it is possible to equip an automatic storage system, reduce personnel labor costs if there is an elevator and stairs. It is possible to assemble and dismantle such a structure without special equipment and tools, such equipment is mobile. To work with a load at a height of about 3 m, personnel do not need any auxiliary machinery. Mezzanine racks are presentable and tidy.

Views

Manufacturers offer different types of mezzanine structures, each of them has its own distinctive characteristics and features, but at the same time they all have the advantages listed above and will become indispensable equipment in any warehouse.

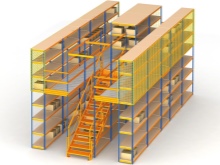

Hinged

This is a variant of the same type of standard design, which uses a hinged type pallet system. The main advantage of such racks is affordability, as well as the ability to quickly process products without automation. For the base of the structure, support beams are used, which are covered with a stable and durable flooring.

The main task of hanging mezzanines is to expand the storage space by building up or adding new tiers. Thus, the design will become a budget option to save time and money.

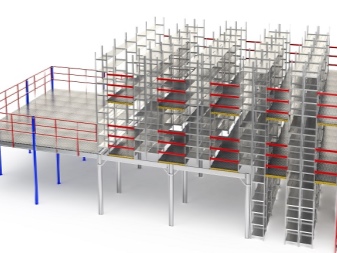

Freestanding

Such racks are often used in large warehouses. This type of mezzanine belongs to the category of complex structures that are made of durable steel, they are created in several floors, the number of tiers can reach four. Each individual regiment fulfills its task. For example, one part can be used for a warehouse, the second is for an office, and the third is used for the production department.

This type of mezzanine is often called a column mezzanine, this is due to the fact that standing racks are distinguished by their power, stability and reliability. As for the equipment, it is quite simple, because it consists of a flooring and columns. At the same time, additional elements in the form of walls, lifts, lifts and railings with fences can be used, which ensure not only comfortable operation, but also safety. Shelving racks are often custom-made according to the customer's drawings and wishes.

Combined

Floor structures consist of various storage equipment. The system can be equipped with pallets, cantilever or shelf racks, therefore such structures are made exclusively to individual order.

The buyer can show all his imagination and make demands on the size of the shelves, the presence of an elevator or other mechanism, stairs with handrails and other devices in order to optimize the system.

Applications

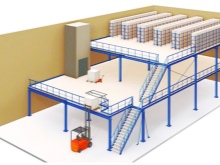

Having studied the technical characteristics of mezzanine racks, we can say with confidence that it is difficult to do without such structures in factories and in warehouses due to the presence of a number of advantages. Therefore, it is not surprising that there are many areas in which such systems are used. Often, structures of this nature are installed in the warehouses of various manufacturing enterprises, where it is required to quickly ship goods that are in storage and complete orders.

This also includes the food, chemical, cosmetic and pharmaceutical industries. Such industries release their goods in a small format, so it is not so easy to find certain positions, and in order to facilitate the process, you can install such structures.

Mezzanines do an excellent job with this task and optimize the work in the warehouse. Such technological equipment is used in places where strict accounting is required, therefore, two-story racks are installed in libraries, archives and various educational institutions, although they may have more tiers.

This systematization of products has already proven its worth, moreover, the workflow is accelerated, and processing is fast enough even manually. If the warehouse has a large assortment, it will not be possible to do without installing mezzanines. On such a structure, you can put a load of small packaging, pallets, containers, boxes and various other containers.

It is much easier and faster to ship goods that are on mezzanine racks, and it also makes it easy to assemble goods.

How to choose?

Having studied the main advantages and operational characteristics of mezzanine structures, the question arises of how to choose such systems correctly, what to look for in order to find high-quality, strong and durable racks. Regardless of what type of equipment you are interested in, there are a number of factors that you must always pay attention to, this is the only way to make a profitable investment.

To begin with, it is important to determine the height of the shelves, taking into account the parameters of the room where such a system will be installed. Regarding the dimensions of the mezzanines, it all depends on what kind of cargo you are going to store there. Of course, it is necessary to choose only trusted manufacturers, whose products have already managed to earn trust and prove their quality. When it comes to standard racks, it is important to pay attention to the date of their release. Mezzanines must have certificates confirming their compliance with standards and requirements, also pay attention to the test period.

Many warehouse enterprises order mezzanines according to individual parameters, so it is important to carry out the correct measurements so that the system fits perfectly into the space. The warehouse equipment supplier must have production lines for the production of products. If possible, you can go to production to make sure of the quality of the shelving.

The structural basis of any type of mezzanine equipment is the availability of high-quality and durable load-bearing beams with parallel vertical columns. Make sure the equipment is made of material that is durable and resistant to heavy loads. It should be noted that well-known manufacturers always indicate the maximum permissible load for each tier. The flooring can be made of nets, perforated metal sheets and wood, so it all depends on what kind of goods will be stored on the floors.

Any mezzanine structure must be mobile and lend itself to further restructuring of the frame, because it is collapsible equipment.

One of the important components of the equipment is stairways, which must ensure not only accessible, but also safe movement. If you need to move a lot of goods between racks, pay attention to structures equipped with lifts. Perforated steel ladders are considered reliable; for safe operation, they must be equipped with a railing and handrails to prevent employees from falling.

The quality of the mezzanines is evidenced by the presence of an anti-corrosion coating, thanks to which the equipment can be installed even in a cold and damp room, without worrying about damage to the metal structure. Such racks can be used even in adverse conditions, because they will remain strong and reliable.

Thus, when choosing mezzanines, one should take into account the parameters of the room so that the system fits in size, as well as high-quality manufacturing material and a certificate from the manufacturer. As for the configuration, it all depends on the personal wishes of the customer, because the system can be supplemented with new tiers, shelves, lifts and lifting mechanisms, which greatly simplifies the operation and handling of goods.

Mezzanine racks have become a profitable solution for warehouses, with their help you can solve the problem of missing space and optimally use the space for storing any goods. A wide selection of parameters, types and configurations of equipment allows everyone to find something that meets their personal requirements.

It is safe to say that a structure made of reliable materials, which is made in compliance with all requirements, will serve for many years, facilitating and speeding up all processes at the enterprise.

The comment was sent successfully.