Overview of circular rod machines and the secrets of their choice

Woodworking involves the use of special machines, which are offered in a wide range. Each tool has its own characteristics and specifications, as well as parameters and advantages. Your attention is invited to a more detailed acquaintance with the circular rod machine, which has a number of advantages, you will learn about the popular models and the nuances of choosing the unit.

Device

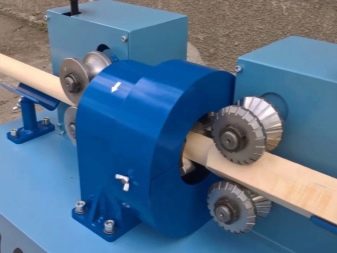

The circular rod machine is a kind of woodworking technique. With this tool, you can design furniture elements and various structures, holders and even frames for construction. The essence of the work of the equipment is to create a cylindrical product, for which a workpiece with a square section is used. This unit includes the cutting part, which is the main element, as well as a block through which lumber is fed. Processing consists in removing excess wood from the workpiece.

The basis of the equipment is made of durable and reliable metal, there are control elements, the material is fed using rollers, which are located in two rows. The machining station includes a shaft with a cutting tool that rotates to form a cylindrical workpiece.

Popular models

There is a wide range of woodworking machines on the market. We would like to draw your attention to the rating of popular models, which have already earned the trust of specialists in this field. The KP 20-50 unit belongs to the tools with which cuttings and other products of a circular cross-section are made. For work, you can use various types of wood. The equipment has a cast iron body with a vortex head. With the help of the unit, you can get a product with a diameter of 20-50 mm.

The next model that you can pay attention to is KP-61, it allows you to create round products, sports equipment, furniture items. Thanks to the adjustment of the cutters, it is possible to obtain a size in the range of 10–50 mm. The KP-62 tool is equipped with double-row broaching rollers, due to which the entry accuracy is ensured. The profile can be fed at high speed. As for the section, it varies from 10 to 60 mm.

Two electric motors are installed on the KPA-50 machine, so the operating speed reaches 18 m per minute, which is impressive. Using such a tool, you can get products with a diameter of 20-50 mm.

The KP-FS round rod unit is equipped with a vortex head, which is characterized by increased power. Such a tool is often used in manufacturing enterprises, with its help it is possible to process beams up to 160 mm. This versatile equipment is often used where a large amount of work is required. If we talk about home workshops, a mini-machine with a low feed rate is suitable here, the number of knives depends on the requirements of the specialist himself. A distinctive feature of such installations is the rotation speed of the heads, which can be from 3400 to 4500 rpm.

Such equipment will serve for a long time and faithfully, with its help it is possible to carry out precise woodworking.

Rigging

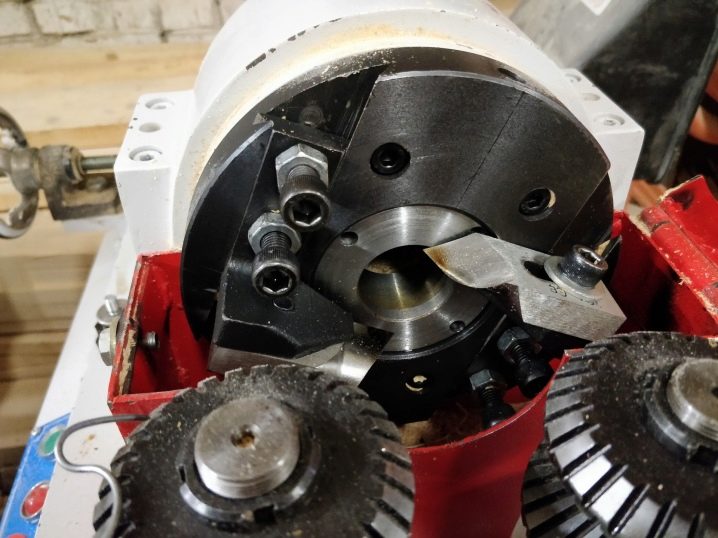

The attachments for the machine are presented in the form of heads and knives, which are indispensable during operation. The swirl head is required for threading, it is mounted on the carriage, there are four cutters inside. A belt drive from an electric motor is used for the drive. With such a tooling, the thread is carried out quickly, a great advantage is the cleanliness of the processing. The cutters guarantee special precision, the process can be carried out in one go, thereby increasing productivity.

The knives for the circular rod assembly are interchangeable elements, with their help you can get several blanks of a circular cross section at once. It is these attachments that are regularly used during carpentry and furniture production. The principle of the knives is to process the material from both sides at the same time. The attachments work from the bottom and top of the board to form parallel ridges. The surface of the final product can be either smooth or embossed.

The knife attachment is made of high-speed steel, so the quality of work is at a height, and the presence of rejects is minimized. For the installation of knives and heads, there are special holes where there are fasteners.

Nuances of choice

Before purchasing a circular rod machine, you need to determine your personal requirements and understand what technical and operational properties the unit should have. For individual work, powerful equipment is not required; you can find a budget option that will serve in a mini-workshop and not take up much space. First of all, you need to pay attention to the power and performance of the equipment. Each machine has its own capabilities and indicators of the size of the workpiece at the exit. Thus, the first step is to understand what exactly you are going to do with such an instrument.

Pay attention to RPM, machine dimensions and feed rate. The machines can be portable or stationary, it all depends on the working conditions.

Operating rules

It should be understood that such a tool has a working part with knives, which must be correctly installed and fixed in order to prevent injury. The round rod assembly should be serviced according to the manufacturer's recommendations. All moving parts are treated with special fluids from time to time. The more often the machine is used, the faster the knives will become blunt, so the sharpness must be checked and restored. It is important to note that there are also several requirements for the procurement. It must meet the parameters stated in the passport, this concerns the section indicator. After long-term use of the machine, it is important to wipe the surface, remove chips and dust so that the equipment will last longer. Security measures involve the use of protective equipment.

The comment was sent successfully.