Features of brick cutting machines and their selection

A brick cutting machine is a special equipment, with the help of which it is possible to make the process universal and significantly reduce the time of its carrying out. The high popularity of such installations is due to the widespread use of bricks for the construction of various buildings and structures.

general description

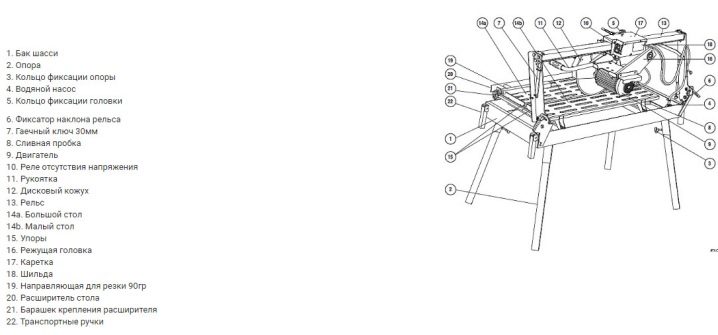

Machines for figured cutting of brick materials are compact devices through which it is possible to achieve the desired result in a short time. With the help of such equipment, it will be possible to organize effective cutting of all types of bricks, regardless of their shape and size. The standard machine design includes:

-

steel frame equipped with a cutting disc;

-

a container for adding water, through which it is possible to reduce the amount of dust;

-

supports on which the equipment stands;

-

a work surface where the brick is fixed for further processing;

-

an electric motor equipped with a drive.

Manufacturers produce reliable structures designed for easy cutting of brick materials, as well as various blocks and products from artificial rocks. Among the advantages of the installations are low weight, ease of use and portability.

Top Models

Brick cutting machines are presented in a wide range, which is regularly replenished and updated. Manufacturers regularly release new models, which significantly complicates the search for suitable equipment. Top 5 best models of brick cutting machines will help speed up the process.

Cedima stone cutting machine CTS-57 G

Equipment of a manufacturer from Germany, which attracts craftsmen with its compact size and reliable design. The machine is designed for precise cutting of all types of bricks, natural stone and even ceramic tiles. Pros:

-

wide functionality;

-

long service life;

-

high performance.

The maximum volume of the container into which water is poured is 50 liters, which ensures long-term operation of the device. Among the design advantages, a strong cutting part and the ability to shift the stop are distinguished.

Diam SKH-600

Brick cutting machine from South Korea, which stands out for its high performance and long service life. Among the advantages of the model are:

-

reliable design;

-

sawing large blocks;

-

professional use;

-

closed water cooling system.

To achieve maximum cutting accuracy, it will be possible to use guides made of durable aluminum and steel bearings with which the structure is equipped. With the help of these elements, it turns out to organize a smooth movement of the working surface and the workpiece.

"Lebedyan SKE 350/600"

Facing brick cutting machine produced by a domestic manufacturer. It attracts with a powerful engine, which makes it affordable to use the unit in enterprises where processing of large volumes of materials and structures is required. The machine can process not only bricks, but also roof tiles and hard rocks. Pros of the model:

-

durable blades;

-

movable table;

-

cooling system;

-

powerful pump.

The equipment is able to work for a long time, cutting various materials, workpieces, regardless of their shape and size.Features of the machine in a relatively low price and long service life.

Fubag A 44 / 420M3F

Another equipment of the German brand, the design of which is equipped with a swing frame. The machine is suitable for cutting brick materials, tiles, rocks. Equipment pluses:

-

high build quality;

-

ease of use;

-

overheat protection.

The surface of the disc is covered with a dense casing, which prevents the risk of dangerous situations while working with the equipment. The main advantage of the machine is the ability to organize cutting with increased accuracy.

Sima Venus 150 Mekano

The cutting machine for facing bricks and other building materials produced by a Spanish brand is suitable for professional use. The model is distinguished by its compact size and low weight, which provides the ability to transport equipment. Among the pluses:

-

cooling system;

-

the ability to adjust the cutting angle;

-

robust construction.

Additionally, the presence of an electrical cable system is noted. This is a design feature of the model, with the help of which it is possible to increase the safety of equipment operation and achieve an excellent result.

Selection rules

Buying equipment for cutting bricks is a complex process that requires a responsible approach. It is important to take into account a number of parameters.

-

Indicator of the permissible load on the working surface. The parameter depends on how much bricks the equipment will be able to handle.

-

Maximum disc diameter. Additionally, it is recommended to take into account the possibility of adjusting the cutting depth. The models have other attachments for this.

-

Maximum cutting error. It should be noted that some brands do not prescribe the indicator in the characteristics. Therefore, when buying, you should give preference to models from trusted companies.

-

Cutting type. Some equipment allows you to organize cutting at an angle, which expands the functionality of the installation.

-

The volume of water to be supplied to the cooling system. The smaller the capacity, the less time the device will operate and the more often it will have to pause.

-

Reliability of the support legs. It is determined by the material and type of frame on which the work surface is installed. And also the indicator depends on the degree of smoothness of the legs.

-

The presence of a steel casing. It can be removable or stationary. It is mainly used to prevent the risk of injury to the operator during the operation of the equipment.

-

Dimensions and weight. The lighter and more compact the installation, the preferable it is. Small devices are easier to move, so they can be used both at the enterprise and at home.

-

The presence of fans that provide additional cooling if the system fails to cope with the task.

-

The presence of a control system that will take into account overheating of the equipment and turn off the engine in time to prevent premature wear of components.

Additionally, you should pay attention to the manufacturer, installation cost and technical characteristics. It is not recommended to give preference to expensive professional models if you plan to rarely use the units. It is best to choose a small standard machine that is ideal for basic tasks.

How to do it yourself?

The master does not always have the opportunity to purchase an expensive installation for splitting brick materials. There is a solution - you can try to make the machine yourself. Here's what it takes.

-

Find ready-made diagrams and drawings of existing machines, which indicate the required dimensions. Subsequently, it will be possible to assemble a structure according to ready-made projects, or come up with something of your own, taking one of the schemes as a basis.

-

Prepare materials and tools. For the machine, you will need to purchase a disk, an engine, a grinder, a carriage and guides.Additionally, you should take care of buying a work surface on which the part will be fixed. If desired, you can also purchase a container for storing water to prevent unwanted dust emissions and act as a cooler.

-

Assemble the installation following the drawing or diagram. It will be necessary to connect the elements in series with each other.

-

Check the operation of the homemade machine.

For more details, see the master class.

If cutting bricks is urgently needed and there is no time to assemble the installation from scratch, you can take a circular as a basis, making only a couple of changes to the design. Basically, craftsmen dismantle the iron disc by installing an abrasive and reinforced disc.

Features of operation

When performing construction work on masonry walls or facing the facade, the master is faced with the need to cut fireclay and any other brick at an angle. A special machine, which can be purchased or made by hand, will help to cope with the task at hand.

Features of the equipment operation.

-

Cutting should be done outdoors. This prevents brick dust from contaminating the equipment and increases the safety of the unit. If a model equipped with a water tank participates in the work, then the unit can be transferred to a workshop.

-

Before starting the engine, it is worth checking the stability of the structure and the sharpness of the blades. Otherwise, you will not be able to achieve maximum accuracy.

-

Work should be carried out in personal protective equipment. You can also use a cotton-gauze bandage to protect the respiratory system. It is worth wearing special glasses to prevent dust and small particles from entering the eyes.

The operation of sawing machine tools with a cooling system will not cause difficulties if you correctly approach the use of the installation and take into account all the recommendations. A brick cutting machine is a popular equipment that is installed both in production and in home workshops. The installations help to achieve the desired result in a short time, which attracts the masters.

The comment was sent successfully.