Description of slotting machines for wood and their selection

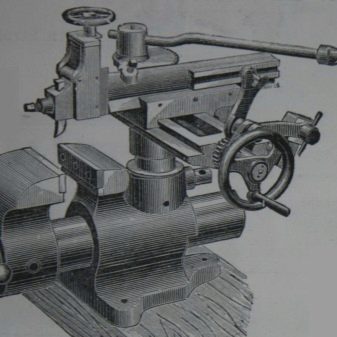

Slotting machine for wood is a popular equipment both in large industrial facilities and in private workshops. It is used for carpentry work, the main purpose of the installation is to form grooves.

Peculiarities

The slotting machine is a reliable unit, the design of which contains:

-

movable block;

-

clamps for workpieces;

-

frames;

-

engine;

-

bit.

The electric motor works on the principle of a pendulum movement, which makes possible the reciprocating movement of the hammer in the structure.

Many people confuse a slotting machine with a milling complex. But both units are noticeably different from each other, despite the fact that the latter is also capable of forming grooves.

The difference between a milling machine lies in the fact that it works according to a different principle. The cutting elements make grooves by rotating rather than moving horizontally.

Views

Manufacturers produce a wide range of slotting machines, each of which differs in configuration, size and other parameters. All models can be classified into two groups by purpose.

-

Professional. The hallmark of these machines is productivity that reaches its maximum limits. Such installations are large in size, capable of creating a variety of grooves, for which they are in demand in production.

-

For home use. This category includes standard hand-held wood slotting machines that operate on the principle of a milling cutter. Household machines are distinguished by their compact size, convenient operation and an ergonomic handle.

The choice of slotting machine is determined by the needs of the user and the scale of production.

If you plan to work with large volumes, preference should be given to dimensional models.

Top Models

The range of table-top slotting machines and professional equipment is regularly expanded and updated. Among the wide variety of models, it can be difficult to choose something that will satisfy all of the operator's needs at once. The ranking of the top 5 best machines will help to simplify the search.

JET JBM-5 708580M

Compact slotting and drilling unit designed for processing wood at home. Great for those planning to make furniture. The advantages of the model:

-

compact size;

-

affordable price;

-

convenient control.

The machine does not have its own complete frame, which must be taken into account before use. A clamp is provided in the lower part of the structure, which makes it possible to fix the unit on the carpentry table in the workshop.

JET JBM-4 10000084M

A modern model of a popular manufacturer, designed for home use. The design of the machine provides a mechanism that ensures reliable fastening of the unit to the surface of the joiner's table. Additional advantages of the model:

-

high accuracy of groove formation;

-

affordable price;

-

the convenience of use;

-

compact size.

If necessary, the machine is suitable for professional use.

"Corvette 92"

A model of a domestic manufacturer, which ideally combines reliable design and high performance. The equipment is suitable for both home and professional use. The design of the machine includes:

-

steel cabinet for tool placement;

-

the base of the frame to increase the stability of the equipment;

-

a working platform equipped with clamps for fixing dimensional parts;

-

a massive block that can be moved along the workpiece.

And also the manufacturer provides a lever that provides convenient control of the unit and increases the accuracy of work.

720HD

The model for professional use, capable of handling large volumes of workpieces. Among the advantages are:

-

high productivity;

-

the possibility of using in furniture production;

-

reliable design;

-

quality components.

The block is capable of moving in any direction in the horizontal plane. The engine is mounted on a steel frame with hydraulic shock absorption.

STALEX B5013

Slotting machine for professional use, which is installed in large industrial enterprises. Suitable for the manufacture and processing of parts for future furniture. Among the advantages are:

-

high power;

-

the ability to process dimensional products;

-

excellent performance;

-

versatility of use.

The design of the unit includes a powerful engine with a provided chisel capable of moving in any direction in a vertical plane. The control is carried out by means of an ergonomic handle.

Selection Tips

Slotting machines have not only different characteristics, but also different devices, dimensions and even purposes. Therefore, the choice of a suitable installation should be approached responsibly. Masters recommend taking into account a number of factors.

-

The maximum degree of tilt of the sled. It is registered in the characteristics of the model. The quality of the products produced from the machine and the productivity of the complex as a whole depend on the parameter.

-

Availability of instructions for use. It should come with every machine. If the equipment is not equipped with a similar document, then it is worth giving preference to another model.

-

Type of drive. The simplest units are equipped with a manual drive. More expensive models include a hydraulic or electric drive, capable of handling large volumes of various wood blanks. For home use, a machine with a mechanical drive is quite suitable.

-

Performance. The quality of the products produced by the machine directly depends on the parameter. Performance is determined by power, and there is a directly proportional relationship between the two indicators. Therefore, for professional use, preference should be given to high-power models.

Additionally, attention should be paid to the manufacturer and the cost of the structure. It is not recommended to trust exclusively expensive and functional models. A standard manual machine may be suitable for the workshop.

The comment was sent successfully.