Do-it-yourself garden benches

A comfortable and beautiful bench is an essential attribute of any garden. There are a lot of such products on sale, but you can make them yourself. There are many ways to make a quality garden bench.

Making a classic bench

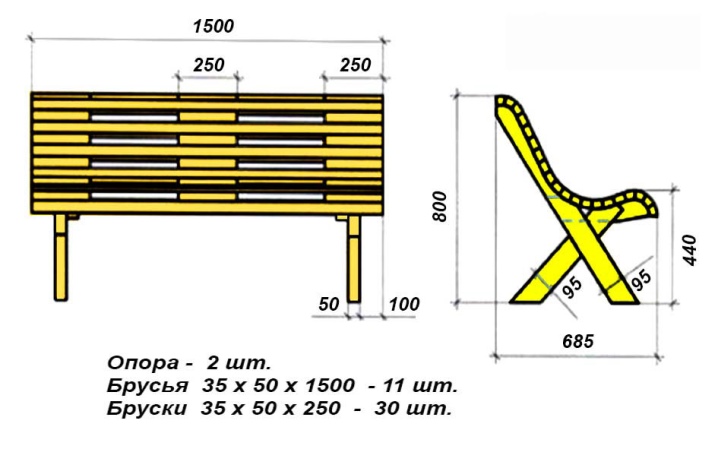

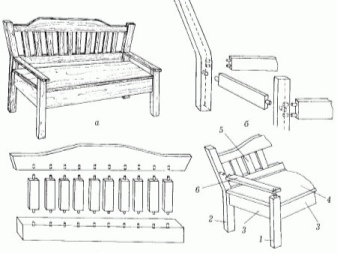

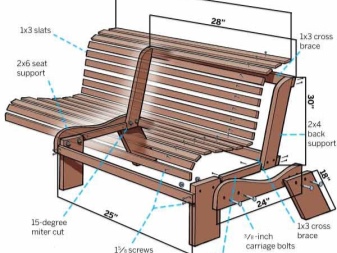

If you do not want to spend a lot of time making a garden bench, it is advisable to build the simplest option. Classic designs can be easily made even by a novice master who has not previously been involved in such works. In fact, all possible varieties of garden benches, whether they are the simplest or English versions, have approximately the same device. They are collected in the same way. First, we will take a step-by-step look at how the assembly diagram of most of these structures from wooden parts looks like.

- The first step is drawing up drawings of the future design. A detailed plan indicating all dimensional parameters will facilitate and speed up the process of making a bench.

- Next, you need to assemble the sidewalls of the future bench. You will first need to make all the necessary holes for the subsequent connection of all elements. To simplify the work, you can use clamps - they will allow you to fix the necessary components of the structure well.

- Then the sidewalls need to be fixed with screws and nuts. Do not forget to put special washers under the nuts. You also need to take into account the fact that you should not immediately tighten them as tightly as possible, since in the future additional adjustment of the fasteners may be needed.

- Next, the sidewalls must be connected to each other. Using a spacer-drain piece, you need to fasten 2 side parts of the future garden bench. Fixation is required to be done using large diameter self-tapping screws. It is recommended to use such fasteners that are equipped with a turnkey head.

- The next step is to secure the parts. The side parts of the future bench must be attached to the back. In this case, it is required to leave a small distance between the parts (5 mm is enough). After that, it is allowed to proceed directly to tightening the fastened components of the structure.

- The final steps - putty putty on the location of the screws on the back of the bench. You will also need to do the cleaning of the structure using sandpaper. The tree must be well processed. Next, the wood must be treated with antiseptic compounds and paint.

When the structure is completely dry, it can be considered ready for use. This is the standard assembly diagram for the most common wooden garden benches. According to the same principle, such structures are assembled in which armrests are not provided. To make the simplest bench of the classic type, you will need to prepare a detailed plan-drawing. When assembling a classic bench, the master can choose different types of backrests.

It is also allowed to change the position of the slats in the structure, for example, to build them cross-shaped.

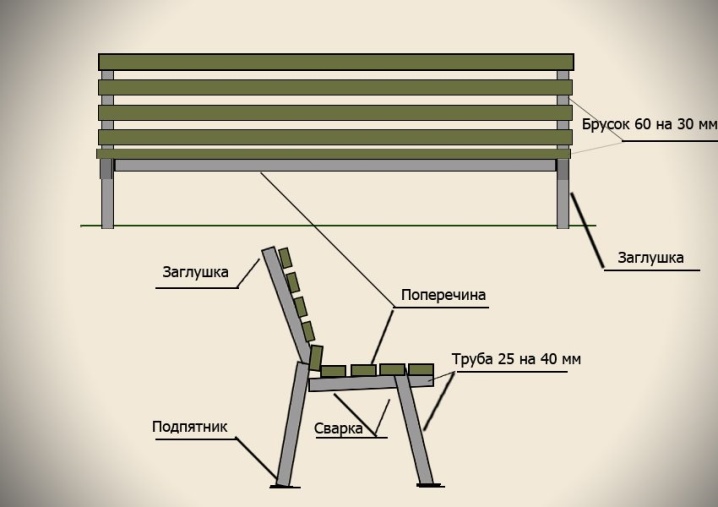

Making a metal bench

Solid and durable garden benches are made of metal. They are stronger and more durable than wooden options. However, they also turn out to be more difficult to manufacture. Let's consider step by step how to correctly make such modifications to the benches.

- For the frame of the future bench, it is best to prepare cold forging. Solid metal frames are the most reliable and practical.

- It is necessary to draw up a detailed plan for the future product. Specify absolutely all the dimensional parameters of the bench. If you doubt your abilities, it is advisable to use a ready-made plan, and not sketch it yourself.

- First you need to make a bench seat. To do this, you will need to take several pieces of pipes with a length of 1500 and 400 mm. Each needs 2 pieces.

- If the above segments are not provided in a ready-made form, then it is worth cutting them on your own, observing the dimensions. In order to obtain the most reliable structure, it is allowed to additionally weld stiffeners to the frame. It will be very easy to cook them.

- The length of the legs of the metal bench can be 460 mm. It is with these parameters that the pipes should be prepared. Also, in addition, the master needs to make sure that the front and rear support parts are well connected to each other. This will ensure a high degree of product stability.

- The back is made so that parts of pipes with a size of 1.5 m and 44 cm are welded to each other. When this action is completed, you should start welding the finished part to the main structure. It is recommended to set the backrest at an angle of 20 degrees in order to sit on the bench as convenient and comfortable as possible.

- To make the back more reliable, it is necessary to provide for stiffening ribs in both the longitudinal and transverse directions.

- Finishing the work on assembling the metal frame, you will need to clean up all the existing joints of the structure. You will also need to carefully polish the metal base, treat it with a high-quality primer.

- In order for the metal bench to acquire a complete appearance, it is necessary to build wooden parts, which will subsequently be attached to the finished frame base. Such components of a garden bench can be made from a board or a bar - these are the most successful and versatile materials.

- Based on the dimensional parameters of the future homemade product, it will be possible to determine the dimensions of the wood components, as well as to think over their fastening direction. It should also be borne in mind that all components of the future shop should have perfectly smooth surfaces, without damage or defects.

- To connect all the prepared structural elements, the master can use an electric jigsaw - it is very convenient and simple to use it. You will also need to prepare all the necessary holes both in the frame and in the wooden elements in order to subsequently fasten them into a single product. Rounded head bolts can be used as fasteners. Nuts can also be used.

- The finishing touch of making a bench on a metal frame is the processing of the wooden components of the structure. The wood must be treated with wood stain or varnish. It will also be necessary to thoroughly coat the natural material with antiseptic solutions in order to protect it from negative external influences.

Often, strong and durable benches with a metal base are complemented by various kinds of decorative components. For example, such a design can be interestingly decorated with intricate forged leaves or flowers - there are a lot of design options.

How to make from scrap materials?

Most often, garden benches are constructed from wood or metal (or a combination of both), but there are other methods of making such products. So, very good benches are obtained from various materials at hand. Let's look at this issue in detail.

Of chairs

A very comfortable bench for a summer residence can be made from chairs. The design will turn out to be as reliable and of high quality as the examples discussed above. To build a similar model of a garden bench, you will need the following components:

- 2 old chairs (you need to choose structures that do not have seats);

- wood rail;

- furniture board or door from a wooden cabinet;

- acrylic paint (the color should be selected according to your own preferences);

- Craquelure means (benches with this design effect look especially attractive);

- decoupage card with images of large flowers;

- varnish;

- brushes and sponge;

- pencil;

- a sheet of sandpaper;

- scissors;

- disposable plate;

- jigsaw;

- screwdriver;

- screws.

Now let's take a look at the step-by-step instructions for assembling a bench from old chairs.

- First, 2 chairs without seats must be placed side by side. They must be pressed as tightly as possible. Next, you need to measure the length of the future garden bench - it will be equal to the length of 2 seats

- You need to cut off 2 wooden slats of suitable sizes. They will need to be arranged in parallel by connecting the chairs. Then the old furniture will need to be fixed with screws. The fasteners must be fixed from the back.

- On the base obtained from 2 chairs, you will need to put a cabinet door or a furniture board. Below you will need to mark with a pencil the future outlines of the bench seats.

- You will need to carefully saw out the seats of the garden bench. For this, it is most convenient to use an electric jigsaw.

- The edges of all parts will need to be carefully cleaned with a sheet of sandpaper. Then the seats will need to be painted with acrylic paint of the selected color.

- The golden paint will look interesting. It should be applied to a sponge, and then formed colored spots on the main structure, making light touches. It will turn out to be an interesting imitation of wear.

- The seat of the bench should be coated with a special product to obtain the craquelure effect. After this, the bases will need to be well dried.

- Next, you need to quickly paint over the bench seat with dark brown paint. On a dark background, golden cracks will appear almost immediately.

- To decorate your garden furniture in an original way, you can use an interesting technique such as decoupage. You will need to cut out images of flowers. Pour some water into a disposable plate and soak the cut out pieces in it. If the paper clippings are thick enough, care must be taken to soak them well in the liquid.

- Now you need to apply the decoupage adhesive to all the moistened pictures. Then they are carefully glued to the base of the bench and dried well.

- The finished construction of the garden bench must be covered with 3 coats of special boat varnish. It is recommended to wait approximately 6 hours after each application.

Out of bed

It will be possible to build a good bench from the bed. This is a very interesting idea for beautiful and reliable garden furniture. Most often, it is the backs from old beds that are used to make a bench. Let's consider how you can build a finished product from these materials.

- One of the backs from the old bed will need to be cut into 2 halves. The halves will be used as side parts of the future garden bench.

- Even if the headboard is not a solid piece of furniture, but is complemented by carved balusters, it will not hurt to build a quality bench.

- A separate wooden board can be used as a seat. Rack boards are also quite suitable instead.

- The second backrest from the old bed can play the role of the foot of the garden bench, located on the front edge. The bottom frame of the product can be paved with an edged board, and then painted. A good solution would be to install a cut-out one-piece shield, which was subsequently laid on top of the frame.

- To make a bench from the bed, you can only take the back, and make the frame itself from fresh materials with your own hands.

Such models of benches are very original and attractive.If everything is done correctly, the structures are very reliable, sturdy and comfortable.

From edged boards

Garden benches from edged boards turn out to be easy to manufacture. Similar designs can be made with or without armrests. Options treated with a noble dark stain or paint of a saturated shade look especially elegant and soundly. The side sections of such products are often supplemented with convenient stands for storing books and magazines or other items that the owners choose.

To make a high-quality bench from an edged board, as in all other cases, it is necessary to prepare a future plan and design drawing in advance. The corners of the wood trim can be tilted 30 and 60 degrees. It is necessary to take these parameters into account when drawing up a drawing. The board should be cut into the required lengths. Then you can proceed to the assembly of the structure using bolts, nails or screws.

From foam blocks

If you want to make the strongest and most reliable structure, you should consider the option of using foam blocks. They can be used to make excellent garden furniture that is both comfortable and aesthetic. Sometimes you can find such blocks, in the internal structure of which there are characteristic holes. They are necessary to enhance the heat-shielding characteristics of the block material. The holes mentioned can also be used in the process of assembling a garden bench. For this purpose, it will be necessary to install foam blocks in 2 rows so that the holes are directed to the side. Bars of the appropriate section must be inserted into these holes. To sit on such a structure as comfortable as possible, you can put soft foam cushions on top. It is advisable that the latter be sheathed with waterproof woven material, because they will be outside.

Foam blocks are allowed to be painted in a variety of colors. Here the owners of the suburban area can show imagination and choose the shade that they like the most. Painted foam block benches look especially interesting and bright.

Helpful hints and tips

If you are thinking of building a reliable and beautiful bench for your garden with your own hands, it is advisable to arm yourself with some useful tips and tricks regarding such work.

- If you decide to build a quality wood bench, be especially careful when choosing natural materials. In no case should there be any defects, traces of rotting or mold on the wood - such materials will not last long, and the appearance of the product will be badly affected.

- Any material for self-manufacturing of a bench must be selected with a margin. It should be borne in mind that the percentage of losses when cutting parts of the required dimensions will be approximately 10%.

- If you are making a bench seat from wood and have planned to build it wider, you need to remember that the material can bend in this case. If a supporting frame is not provided, this will surely happen.

- When sanding wood, try to act as carefully as possible. In no case should there be sharp protruding parts on the surface of the backrest and seat. If you do not pay attention to this, later people can get injured using poorly processed garden furniture.

- All pointed and angular parts of the bench are recommended to be corrected at the stage of its manufacture and assembly. So you will protect yourself from possible injury during the operation of the structure.

- Think in advance about the design of the future garden bench. Please note that garden furniture should blend in harmoniously with the surrounding environment.

- Never neglect the treatment of wood parts with antiseptic solutions. The fact is that they are designed to effectively protect natural material from decay, drying out, mold and destruction under the influence of moisture.If you do not smear the tree with antiseptics, it will not be able to last long.

- Many owners of summer cottages decide to install a bench around the tree trunk. If it is a young, growing tree, it is necessary to provide sufficient free space between it and the bench. Otherwise, over time, the growing trunk will simply destroy the garden furniture.

- If you do not have rich experience in assembling home or outdoor furniture, it is recommended to use ready-made diagrams and drawings. It is better to resort to self-preparation of a work plan only when you get more skills through experience.

- When assembling a homemade bench, always check the horizontal and evenness of all structural parts. If you notice even the slightest distortions somewhere, you must immediately get rid of them. If you put off working on mistakes until later, you will have to spend even more time and effort.

- If you can't put together a high-quality garden bench on your own, and you are afraid to translate even more material, it is better not to waste your time. Go to the store and find the best bench model for yourself at an adequate cost.

Beautiful examples

A well-made bench can become a real garden decoration. Let's take a look at some good solutions.

- A wooden bench with a back and armrests painted in dark brown will look solid and presentable in the garden. The X-shaped wooden slats on the back will be a suitable decor.

- A solid bench on a wrought-iron base with graceful patterned legs and armrests will become a chic detail of any garden. On such a frame, the seat and backrest, made exclusively of noble wood species, painted in a beautiful shining color, will harmoniously look. To make the design more elegant, it is worth using a smooth curving transition from the seat to the back.

- Wooden benches with aging effect look very impressive and original on garden plots. Such structures may have artificial scuffs or a pronounced woody structure. If such a bench is painted dark brown, it should be placed in a place surrounded by light floral plantings - the tandem will turn out to be amazing.

- Solid benches made of sawn logs look interesting and unusual. In such designs, the legs can also be made from smaller sawn logs. A bench like this will always draw a lot of attention to itself against the backdrop of lush garden greenery.

- The garden bench can be made entirely of metal. Often, such designs are not supplemented with soft seats, since with the correct execution they are still comfortable to sit on. For example, this might be a small bench with a high patterned back and slightly curved armrests. The model will be more attractive if painted in a contrasting black color. In the garden, such a detail will definitely not be lost.

For information on how to make a garden bench with your own hands, see the next video.

The comment was sent successfully.