Features and manufacturing of benches from a bar

In terms of strength and aesthetics, benches from a bar significantly outperform products from boards. The beam is quite heavy, so benches made of it are often installed on the street: in the garden, in the country, next to the gazebo. Consider the features, pros, cons and subtleties of making benches from a bar.

Advantages and disadvantages

Lumber benches are very popular among the owners of cottages and summer cottages. Products are also installed in public places for recreation: for example, in parks. These benches are very popular for many reasons.

- The timber has a low thermal conductivity, it is environmentally friendly. The material remains warm in cold weather, does not heat up very much from the sun's rays.

- The timber is characterized by increased resistance to heavy loads. The bench will not bend from the weight.

- Boards are less durable than timber.

- Since the edges of the timber are very even, products made from such material look very aesthetically pleasing.

The main drawback of a bench made of timber is its significant weight, but it can also be counted among the advantages, since such a bench is very stable. However, it is not easy to transfer from one place to another. So that the garden bench made of timber does not cease to look aesthetically pleasing, it will have to be regularly looked after. You will need to apply an antiseptic on the surfaces twice a year so that they do not turn black. It is also necessary to cover the garden bench with linseed oil or varnish.

In cold weather, the bench is recommended to be removed to the barn. If this is not possible, you should at least build a reliable film shelter. The bench will start to rot if you keep it damp often.

Varieties

There are a variety of benches from a bar: standard, design. The most popular are standard designs, but it should be borne in mind that with a creative approach, real masterpieces are built on their basis.

By installation method

By the method of installation, timber benches are divided into such.

- Stationary. They cannot be moved or moved. Such structures are buried in the ground, concreted.

- Portable. The legs of these benches are not attached to anything. Even if the bench is very heavy, it can still be moved somewhere else.

By design

There are a lot of shapes and designs of benches. They are conventionally divided into the following.

- Simple. These benches are made without backs, they are not made for long sitting. Such structures are installed where people usually want to relax. A simple bench can be built from a 25 mm thick board and a 50x50 mm bar.

- With a back. Such benches allow people to rest for a long time and take positions comfortable for the body.

- Difficult. Such shops are not only intended for relaxation, they also decorate the territory. You can depict various recesses on the legs, decorate the bench with carved armrests, an aesthetic back.

If you are going to create a shop, you will need to decide for what purpose you are doing it. So it will be easier to decide on the type of structure, its height, width.

Tools and materials

The timber in our case is the main building material for the manufacture of a bench, it should be given special attention. Focusing on the load for which the bench is designed, they are determined with the type of workpieces.It is recommended to choose solid timber for benches: for example, oak. Coniferous wood does not work very well, because resin is actively released from it. The following types of timber can be distinguished.

- One-piece non-profiled solid timber - the simplest and most affordable material, but it should be borne in mind that it has not been processed. It has natural moisture, cracks and fungus can appear in it. In addition, a one-piece non-profiled beam is rather difficult to lay.

- One-piece profiled timber is processed. It has high-quality surfaces, resistant to moisture, a complex cross-sectional profile.

- Glued profiled timber create from separate blanks, lamellas, which are glued to each other. This material is very durable, it is treated with special impregnations, which ensure the durability of the bars. Glued laminated timber is quite expensive, but it will ensure the aesthetics of the appearance of the structure for a long time.

- Thermobeam. Inside it there are special blocks that increase the heat-saving performance of the building material. Such a bar does not have to be additionally insulated.

To make the country bench more stable, you can, for example, combine a bar with cinder blocks: this is a type of building stone. The use of foam blocks is possible. Some people choose WPC bench beams, an alternative to regular wood. The wood-polymer composite does not have to be hidden from the rain and cleaned for the winter; such a bench bar is distinguished by its significant resistance to various atmospheric phenomena.

The bench can be made not of a wooden, but of a plastic bar. Such material practically does not fade, does not light up over time. It is not painted like wood. Paint on a wooden surface can melt, become sticky and start to stain anything that leans against it.

To create a bench, you may need the following:

- hammer;

- chisel;

- saw;

- screwdriver;

- plane;

- drill.

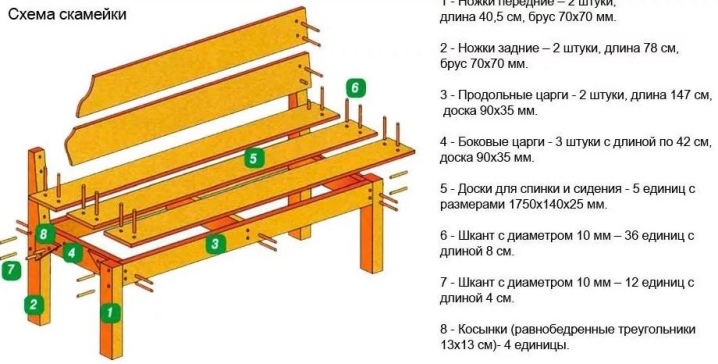

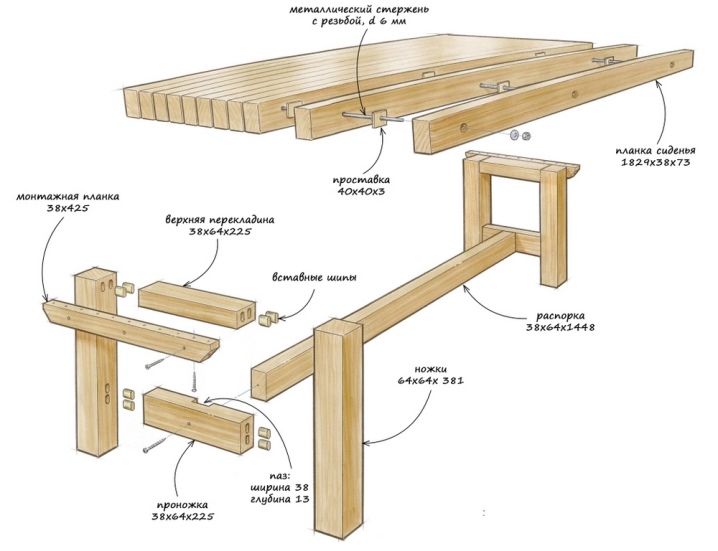

Dimensions and Drawings

Before creating a shop, it is recommended to draw up a drawing, it will be much more convenient to build a structure on it. The size should be determined so that a person is comfortable on the bench. The distance from the ground to the seat element is about 45-50 cm: based on this indicator, the length of the supports is chosen. If the bench is installed motionless, stable, the legs should be longer so that they can be fixed in the ground.

To make it as comfortable as possible, you can tilt the seat slightly (up to 20 degrees). Its optimal width is approximately 45 cm. The height of the backrest is from 50 to 60 cm. In this case, you can also tilt it at a slight angle or leave it straight. If the bench is intended for many people and is designed for a large number of seats, it is recommended to choose a material 100x100 mm, 150x150 mm. It is possible to use a rectangular section: for example, 150x100 mm. For children's benches, wooden bars of a smaller section are used.

How to make a simple bench?

If the bench is stationary, you will need to dig the supports into the ground. If it will be portable, it should be equipped with four supports for stability. It is recommended to install a jumper between the two supports. With the help of a long bar, opposite supports should be connected to each other. It will become a spacer that will prevent the bench from loosening. The seat should be supported and secured with bolts. The following options are possible: connect several elements or choose a rather large board as a seat.

Do-it-yourself bench with a back

It is pretty easy to create a bench with a back. Legs can be made X-shaped. Small and large bars will be needed for each support on the sides. At an angle of 30 degrees, connect them with the letter "X". The long bar will, as it were, continue the base. A jumper should connect opposite supports to each other. At an inclination, you should slightly cut off the lower part of the legs so that they stand as securely as possible on the surface. The crossed supports are connected with a bar at the height at which the seat is fixed.

The boards should be bolted to it. At the end, the bench should be sanded and varnished.

Product from the remaining bars

Some owners of summer cottages are building a simple bench from the remains of a timber that, for whatever reason, was not used during construction work. Make stable supports from blocks of different lengths: stack the pieces in a stack, like a pyramid. To connect the support elements, attach a bar on the side, screw it to each part of the structure with self-tapping screws. Place the rectangular seat on the support elements. Bolt the two legs of the backrest base in an inclined position on one large side. At the end, the bench should be sheathed with a board.

Product from cinder blocks and timber

An unusual bench without a back can be built in a few minutes. The shop will be collapsible. It can be used as a sleeping place (if you put a mattress) or as a seat. The legs will be incomplete cinder blocks with holes made through. How many cinder blocks are needed depends on the width of the bench. It will take 8 blocks if the seat consists of 4 bars, 6 blocks for 3 bars.

It is necessary to select the bars along the section so that they can be inserted into the through holes of the cinder blocks. If necessary, cut off the ends (if they do not pass in any way). To give the shop aesthetics, you can paint the cinder blocks with a multi-colored facade water emulsion. For this, a paint and varnish material in a balloon is suitable. In an upright position, place the colored blocks opposite each other. Place the ends of the bars inside the windows. To give the bench more stability, you can tighten the cinder blocks of each support with a belt.

Bench around the tree

In this case, the seats are arranged in a circle. A bench around a tree can be built in the shape of a quadrangle, square and other shapes. It will take a lot of legs if there are many corners, because supporting elements will be needed to install the seat in all corners. The benches are buried in the ground: it turns out to be stationary. First, the required number of legs is fixed where needed. First of all, the long bars of the seat are fixed, then they proceed to small workpieces.

Such benches can be made with backs, but most often they do without them.

Corner bench

The corner bench will look good in the country, next to a country house. It is necessary to create an L-shaped frame from a bar, then you need to divide the frame inside into square parts using jumpers. They will make the structure more durable. Then the legs from the bars should be attached to the frame. A small table can be placed at the junction of the two benches at the corner. To raise the top of the table, you need to raise the square in the corner. You can simply put the bars horizontally, but it is better to install racks from small scraps and connect them on top using wood elements. In the niche of the table, you can place a drawer. Finally, plank the seats of the benches. Multi-ply plywood can be used to create the countertop.

Registration

When decorating a shop, you can use all your imagination. A popular option is various patterns and patterns on the surface, this design method is especially well suited for a children's bench. Wood aging technology is also very popular. You can lightly walk on the surface with a chainsaw chain, a metal brush, gently burn the bench with a blowtorch. You can also cut patterns on the board and attach it to the back of the bench.

For information on how to make a bench from a bar with your own hands, see the next video.

The comment was sent successfully.