All About Canopy Benches

Many people who have their own country homes with plots organize large outdoor seating areas. Often, comfortable benches with awnings are purchased for this. These designs can be of various types. Today we will talk about the features of such shops.

Advantages and disadvantages

Benches with a canopy for summer cottages have a number of important advantages.

- Sun protection. The awnings are made of special durable materials that do not heat up and reflect the sun's rays, which provides maximum comfort.

- Simple manufacturing technology. You can make a canopy yourself. It doesn't take much time and effort.

- Takes up a minimum amount of space. Such structures will not occupy a large area, in addition, there will be no need to place additional structures to protect from the sun and rain.

- They can serve as a decoration for the landscape. Often, such designs decorate summer cottages, they are made with various additional interesting details.

Despite all the important advantages, garden benches with a canopy also have some disadvantages.

- Considerable weight. As a rule, models with canopies have a large mass, if necessary, it will be more difficult to rearrange and transport them.

- High costs. If you want to make a similar structure for rest with your own hands, then you will have to separately buy consumables and accessories for the frame.

Description of species

Street benches with a canopy, standing in the courtyard of the house, can be made in various versions. Let's consider the most common models.

Single

Such designs are made without linking with other parts. At the same time, the frame part of the backrest rises up and joins the small visor. It completely covers the seat.

Single models can be placed both in the depths of the garden and next to the house. Often, whole dining areas in the open air are formed from such products.

Twinned

Outwardly, such models resemble standard gazebos for relaxation. In this case, two benches are connected to each other using a frame base. It is sheathed with roofing material.

The double benches have an arched design. As a rule, benches are set opposite each other. A small table is placed between them. Like the previous version, such models are used as a dining area in the yard.

Swing benches

Oscillating models are robust structures in which the seat is hung on a secure canopy frame. Thus, it will be in limbo and can swing.

Transformers

These models are considered the most convenient and practical. They represent a structure with a back, which is equipped with a special mechanism. It allows the product to be laid out in two benches and a small table.

Transformers with a roof are designed in such a way that when unfolded, the back side of the back turns into a table top. The seat simply becomes divided into two halves. The canopy in this case will cover all the constituent elements at once.

You can watch the detailed folding process in the video below.

Materials (edit)

A variety of materials can be used for the back and seat. Most often, a tree is taken. At the same time, the wooden base should not have even small cracks and knots.

To create benches, it is better to take carefully dried material. When choosing, it should be borne in mind that the breed should be as resistant to various atmospheric influences as possible. The most suitable varieties will be such as hazel, oak, larch.

A more affordable material, but at the same time less resistant to external environmental factors, is pine. Children's benches or decorative benches for placing flowers can be built from birch.

Metal can also be used to make the back and seat. Most often, they take a profile strong pipe. This material is considered more reliable than the previous one, but at the same time it will heat up much faster even with a canopy.

Often, only a bench frame is made from a metal pipe. And to create the seat and back itself, they take wooden elements. Such models are considered to be quite durable and reliable.

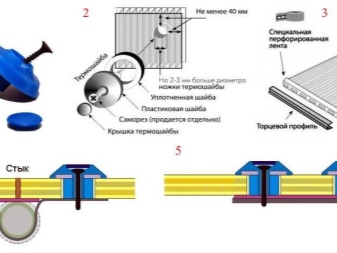

The canopy itself is recommended to be made of polycarbonate. This material provides good protection against the adverse effects of UV radiation. In addition, such elements are lightweight and easy to install.

Polycarbonate is available in different colors. The choice will depend on the person's personal preference. The material does not require special care, has an affordable cost.

Where to locate?

Before you start making a garden bench with a visor, you should decide in advance on its location. Such structures are recommended to be located close to beautiful green spaces.

The place must be well protected from wind currents in order to provide maximum comfort for the holidaymakers.

Benches with roofs can be placed in the garden itself, and next to buildings, with flower beds, with shady tall plants.

How to do it yourself?

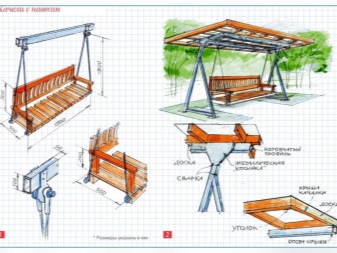

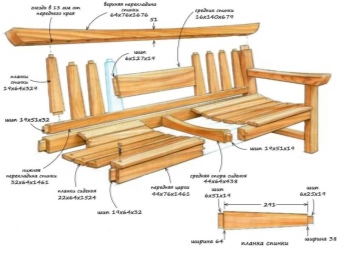

If you do not want to buy such benches for your garden, you can do them yourself. First you need to choose a suitable drawing for the manufacture of the future product. You can find a ready-made scheme with all sizes on the Internet.

When you find a suitable project, you need to prepare all the necessary materials.

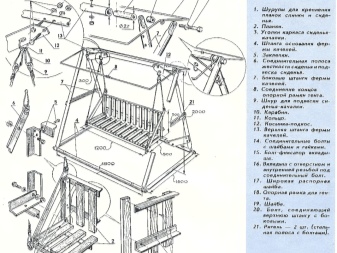

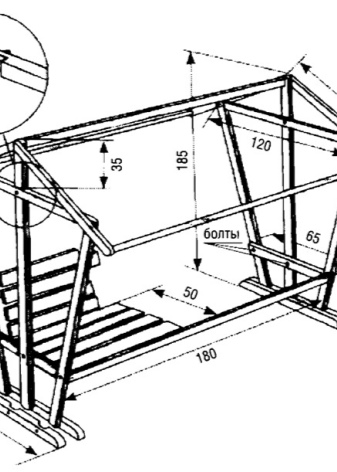

- The frame is made first. The seat support is made from four sturdy wooden beams. It will be at a distance of 45 centimeters from the surface of the earth. To connect the component parts, it is better to use screws made of stainless steel.

- Then you need to attach the seat support. First, the front pillars are installed, and later the rear part is also mounted. In this case, it is better to double-check the height using the building level.

- Then you can start supporting the seat. For this, backs and armrests are built around the perimeter. These details will make the structure quite rigid and stable.

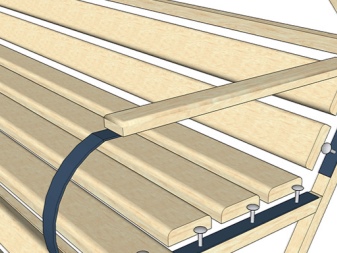

- Later, the slats are installed on the seat. They are driven in a few centimeters. The strips are secured with a few stainless steel screws. They should be placed every 15 centimeters.

- Next, it is worth starting to fix the jumpers. To do this, small notches are carefully cut out in them. Fastening is made from groove to groove. In this case, special glue, clamps and screws are used.

- Finally, the materials are coated with a protective transparent varnish. It is better to apply it with a brush in a thin layer. After that, the coating should dry completely. At the same time, you can start producing the canopy.

- Pieces of polycarbonate are cut out depending on the size of the bench made. The resulting segments are attached to the frame using fasteners.

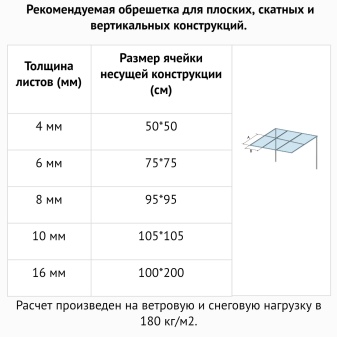

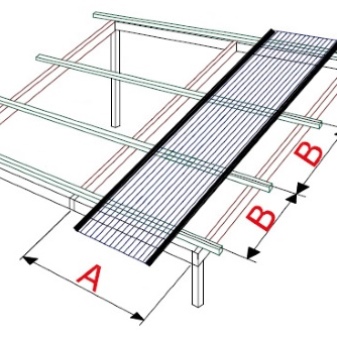

- For the manufacture of awnings, polycarbonate 6 mm, 8 mm, 10 mm, 16 mm is used. Too thin sheets should not be used, since excessive load from atmospheric precipitation can deform the material.

- As an additional support for the canopy, you can take a special fine-mesh crate. During manufacturing, all metal parts should be treated with a special anti-corrosion protective compound.

You can make a bench using a different technology.

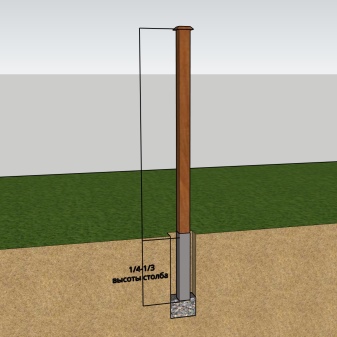

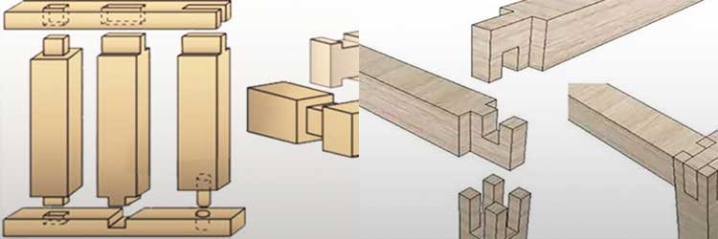

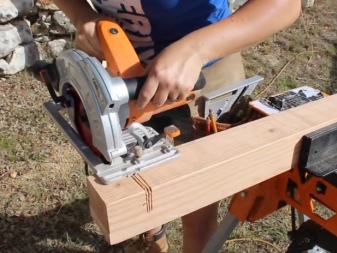

- First you need to make supports in the form of small pillars. It is better to make parts with a section of 100x100 millimeters. For this, it is better to take a circular or miter saw.

- After that, a sample is made from one edge. In this case, markup is performed in advance. The cut part of the wooden bar is removed. Next, the groove is finalized so that it can acquire the desired shape.

- It is recommended to sand the edges immediately. This will avoid splinters while working. In order for the pillars to be sufficiently stable, a base is made separately, which should consist of horizontal material and slopes located at an angle of 45 degrees. Parts should be cut from the same bar.

- Later, using a construction tape, you need to find the place where the slopes and support are connected. They put a small mark there. The elements are attached to each other using self-tapping screws.

- The pieces will be tied at the base with two wooden planks. After that, the parts are cut off, all this is fixed with self-tapping screws. In this case, galvanized fasteners should be used.

- Next, the crossbar is cut out. You can take the same wooden beam. Connections are formed in half a tree. In this case, you should leave a small decorative edge so as not to spoil the appearance of the product.

- In order for the frame to be able to withstand all the loads in the future, you need to install slopes at the upper corners. Next, they make a canopy. It is better to build a gable type structure. In this case, a jumper made of a wooden board will act as its base.

The comment was sent successfully.