Making wood benches with your own hands

Wood is a versatile material that can be used to create a wide variety of things. For example, it can be used to build very comfortable and beautiful benches. Ready-made structures are placed on the veranda, in the yard and in any other areas. In this article, we will learn how you can make a good wood bench with your own hands.

How to make a bench with a back?

The most comfortable and practical benches are those with a backrest. It is much more comfortable to sit on such grounds, because the back of a person at this moment also rests, does not experience tension.

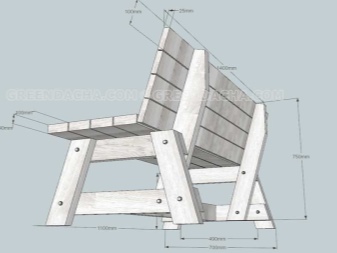

A bench with a backrest is quite easy to make. The main thing is to act in stages, relying on previously drawn up diagrams and drawings. On the project of the future design, the master must indicate all the dimensions and features of the future product. If you have a sketch of the planned craft at hand, it will be much easier to make it, while avoiding serious mistakes.

Let's consider in detail what steps the process of making a comfortable bench with a back consists of.

Instruments

The first thing a home craftsman should do is to prepare all the necessary tools, coupled with well-chosen materials. The boards from which the bench will be made must be of high quality, without traces of destruction and rot. In addition, the master will need to stock up on such tools:

- glue for wood;

- a sheet of sandpaper;

- primer and paint;

- brush;

- screws;

- Circular Saw;

- drill with a set of different drills;

- countersink bit;

- electric jigsaw and hacksaw;

- plane;

- clamps and tape measure.

It is recommended to keep all the tools close at hand, in one place. Many craftsmen neglect this simple rule, which is why they waste a lot of extra time looking for the necessary device.

Work progress

If all the necessary components (both materials and tools) are prepared, you can proceed directly to the manufacture of a high-quality bench with a back. The master must necessarily act in stages, without neglecting any of the steps. Let's consider in detail the progress of work.

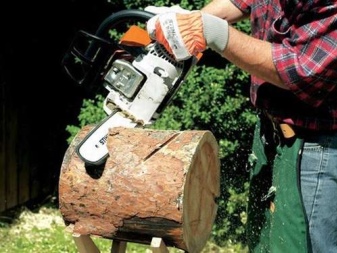

- Based on the parameters reflected in the previously drawn up drawings, it is necessary to cut blanks from wooden boards for assembling the bench.

- All wood surfaces must be properly treated. For these purposes, an electric or manual plane is perfect. Of course, things will go easier and faster with a power tool.

- Next, you need to carefully cut off the oblique sections from the backrest supports and the lower transverse parts.

- The next step is to assemble the supporting structures of the future bench. Nails or self-tapping screws can be used for fasteners, but they may slightly loosen the connection. When connecting different elements, it is worth checking the position of all components using a square.

- The supporting components of the timber structure must be securely connected by means of the lower crossbar.

- Several slats are fixed on top, which will form the plane of the bench seat.

- Next, you need to carefully and firmly fix the planks, which will play the role of the back of the bench.

- The assembled structure is carefully processed with a grinding machine, getting rid of all sharp edges, roughness, burrs and other defects that could remain after working with the plane. It is recommended to remove the chamfers so as not to accidentally splinter hands or other exposed areas of the body.

- A well-sanded structure will need to be coated with 2 layers of paint. You must wait until the product is completely dry before applying the next layer of paint. Sometimes interlayer sanding is performed, which can make the surfaces more accurate and smooth. There are no special requirements for the number of layers, the master must be guided exclusively by the appearance of the structure.

The resulting bench can be placed in the yard or on the veranda. If all the actions were correct, the wooden structure will turn out to be strong and durable.

Options for creating simple benches without a back

Well-made benches with backs are undoubtedly very comfortable, but this does not mean that models without backs are less comfortable in use. With your own hands, you can make a very good model of a bench that does not have support under the back.

There are many options for creating a beautiful and durable bench without a back. In the manufacture of such structures are simpler. Even an inexperienced home craftsman can easily cope with the work of creating such a bench.

To assemble a high-quality bench without a back, it is also necessary to prepare detailed drawings in advance, purchase materials and tools. A very good and easy-to-assemble structure can be built from planks and beams with rounded edges. From the last details, it will be possible to make strong and reliable supporting elements of the bench. For such purposes, you can also use small logs processed along the edges - the effect will be the same.

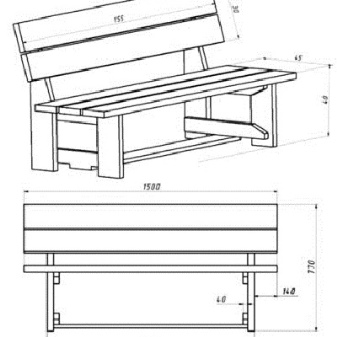

Let's figure out how to make a beautiful bench without a back, 120 cm long, 45 cm wide and 38 cm high.

- It will be necessary to carefully round off all sides of the timber. A high-quality milling machine is best suited for this. Some craftsmen prefer to immediately buy prepared bars that do not need to be further processed. These parts are more expensive, but it is much easier to work with them, and time is significantly saved.

- Based on the selected section of the timber, you need to correctly calculate the length that will be needed. Determine how many bars will need to be stacked on top of each other to achieve the planned height. For example, it can be 5 bars per bench leg.

- The seat can be made from a 40 mm thick and 90 mm wide board. For the seat, you will need to prepare 5 boards 1.5 m long.

- First of all, the parts are cut from which the seat of the future bench will be made. They must be cut and carefully processed - this is a very important point in the manufacture of a structure. If the master does not have a high-quality milling cutter or sander in use, you will have to work with ordinary sanding paper.

- It is necessary to cut the boards of equal length, grind them and be sure to coat them with varnish.

- The legs for the legs should be laid out next to each other, trimming the edges. Using a pencil and a square, draw lines where the fasteners will be installed. There should be a distance of 7-10 cm between the strips.

- Wood or metal pins can be used. Holes must be drilled under them. Then they are hammered into one piece, and a second piece must be inserted into the same hole from above. The fasteners will turn out to be strong, but for additional confidence it will not be superfluous to add a little adhesive composition.

- The pins must be staggered. The supporting legs of the bench must also be secured with pins. If the seat has been nailed, it is advisable to take some mastic for a suitable shade of wood, add sawdust to it and stir everything.The resulting composition should be smeared with all areas with connections, and after drying, they are treated with sandpaper. All elements are sanded to smoothness and coated with either varnish or paint for outdoor use.

How to fix different parts of such a bench - each master decides for himself. Of course, fastening by means of pins will be more difficult than in the case of using nails.

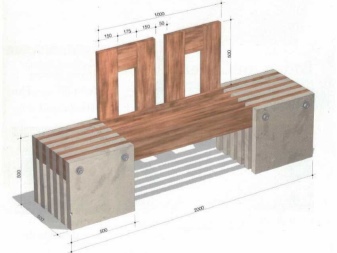

An excellent bench without a back can be made from a successful combination of materials - wood and concrete slabs. In manufacturing, the design will be very simple, but it will have a more solid appearance. To build the specified option, you will need:

- boards with a thickness of 3.8 cm;

- 12 concrete slabs.

Such a model of a bench is made as follows.

- All 2 meter boards need to be marked. It is necessary to indent from the 2 ends of each part by 10 and 40 cm. In the middle of the boards, set marks, drill holes in them.

- It is necessary to mark out the concrete slabs as well. Leave the indentation from the top edge 7.5 cm, and from the right and left - 10 cm. At the intersection points, set more marks and drill holes.

- Treat all wooden components of the bench with an antiseptic solution, let them dry.

- Move on to assembling the bench seat. Place the plates between the boards, install the M16 threaded rods into the prepared holes (there should be 4 of them). Fasten the rods with washers and nuts. It is recommended to twist them at the same time from different sides.

- Treat wooden components with varnish.

In the same way, you can make an original bench with a back. The structure will have an interesting decorative look and will decorate the local area.

A very strong and durable bench without a back is quite possible to assemble using a metal profile. The design will turn out to be not only wear-resistant, but also aesthetic, made in modern style. Consider how you can build such a bench yourself.

- Rectangular parts must be welded from the metal profile. Small jumpers should be welded to the walls on the sides - boards that will be used as seats will rest on them in the future.

- It is possible to assemble a more advanced model with armrests, backrest, cozy pillows. In this case, the wide seat transforms into a real comfortable sofa.

In production, these structures are elementary. The main thing is to buy metal parts and wooden boards. In addition, the home craftsman should be familiar with the work of the welding machine.

Then the bench (both simple and more comfortable) will turn out to be very reliable.

How to make from logs?

There are various types of wooden benches. Different materials are used for the construction of different structures. So, very good options can be obtained from a log. If you make a bench correctly, it will have an attractive, non-trivial appearance.

Tree trunks cut down for old age or land clearing are materials that are easy and simple to interact with. Even novice craftsmen who have not previously encountered the specified raw materials can make a wear-resistant and pretty bench from logs. In this case, as in all of the above illuminated, it is necessary to first draw up a detailed drawing of the future structure indicating the dimensions. With all the drawings at hand, you can start making the bench.

- First of all, the trunk prepared for work will need to be cut lengthwise, so that one part turns out to be larger, and the second one is smaller. The denser part will be used as a seat, and the thinner one will become the back of the structure.

- In the elements of the future bench, it will be necessary to make holes for the installation of metal pins.

- At the final assembly of the bench, the fastening pins will need to be driven into the holes made using a sledgehammer or hammer.

- Wooden components of the assembled structure must be treated with protective, and then decorative (paint or varnish) compounds.

Homemade pallet bench

Few people know, but a beautiful and reliable bench can be built from ordinary pallets. Often, people exhibit such designs not only in the adjoining plots, but also at home. For example, a beautifully made pallet bench can decorate a loggia or balcony and even a hallway. The main thing is to pay due attention to the design of an interesting structure.

Consider one of the ways to make an original bench from pallets for placement in the garden.

- Benches made from simple cargo pallets can be used as garden furniture. Moreover, it is not at all necessary to disassemble them for this. Just one of the parts can be installed as a seat, and from the second you can build a back. All you need are carefully crafted armrests and legs for the support legs.

- One of the prepared pallets must be reinforced at the attachment points by inserting pieces of bars. Having installed the latter, they must be screwed by means of self-tapping screws on both sides.

- From a bar with a section of 100x100 mm, 4 identical parts should be cut in the form of segments 80 cm long. They will need to be screwed in those areas that have just been additionally reinforced. Leave at least 20-25 cm on the legs of the structure. Fasteners should be provided with longer self-tapping screws (at least 150 mm).

- It is very important to maintain the ideal verticality of the structure and leave equal distance for the legs. Only then will the seat be level and stable. If there are even the slightest errors in the height of the structure, you can file the necessary sections a little, but then you will need to saw from above so that the armrests also turn out to be even.

- Another pallet needs to be screwed to the rear legs, and on the sides - boards for fixing the armrests.

- The last improvements remained. You should take furniture foam rubber, sheathe it with textiles. For the back, you can prepare soft pillows. If you did not plan to make such a comfortable bench, it is enough to process the wooden parts with a grinder and paint them in a beautiful color.

The pallet structure is ready. Done right, you have a beautiful loft-style bench that will attract a lot of attention.

How to process?

In all the instructions listed above, among the last points, the processing of wood was mentioned not only with decorative, but also with protective compositions. The fact is that wood is a material that does not tolerate contact with water and dampness poorly, therefore, without additional processing, it certainly begins to deteriorate and rot. Benches built from natural components must be coated with suitable compounds, especially if these are street and summer cottage options.

Different mixtures are used to process wooden benches. Let's get acquainted with the most relevant options.

- High-quality opaque paints of different colors and shades can completely hide the texture of natural wood. Compositions of different types can be used to process garden furniture, but acrylic options are the most reliable and practical. Mixtures with such a base form a more durable and long-lasting coating, which can be of different colors. Solidification occurs in the form of a film.

- There is another popular composition - azure, which in many respects resembles a standard varnish, but in fact it is not. Unlike varnish, with the use of the product in question, a vapor-permeable film does not remain on the wood - the wood continues to "breathe" freely further. Azure will enrich the natural material with rich, deep tones.In addition, the specified product freely penetrates into the wood structure, protecting it from burning out under the rays of the sun, as well as from deterioration under the influence of precipitation.

- Standard varnishes form a film coating on the surface of wooden structures, do not allow moisture and moisture to penetrate under it. The product can be either transparent or with a certain shade. It is recommended to choose yacht varnishes for outdoor furniture, as they last much longer, protect more effectively and shine beautifully in the sun. Colorless varnishes are often applied in combination with different impregnations, for example, stain.

- The oldest solution is the treatment of wooden substrates with oils. Such compositions can easily penetrate into the very depths of wood structures, giving them water-repellent properties, and with this an attractive shade.

Most often, floorings on piers or near pools are coated with oils, which indicates the high protective functions of such compounds.

Helpful hints and tips

Let's take a look at some useful tips for making a high-quality wooden bench on your own.

- To make a good bench, you need to carefully select the natural material. The master must make sure that the wood is not damp, does not have traces of rot or mold. Low-quality material cannot be used to make a durable and wear-resistant structure.

- If you want to make a portable bench, then it is advisable to make it from lighter materials, to get rid of unnecessary weighting decorations. The dimensions of such products should also not be too large. The best solution is a small and tidy bench.

- If the master did not previously make garden furniture with his own hands, then it is better for him to use ready-made diagrams and drawings of benches. Only experienced craftsmen who have previously encountered similar work can draw up accurate and correct projects for any garden furniture.

- At the stage of preparation and fastening of all components of the bench, it is very important to monitor the level and evenness of the structure. It is better to notice and correct any mistakes right away, at the first stages. Otherwise, you will have to adjust all the parts for a long time, trying to align them.

- If you just cover the finished bench with varnish, its surface from this will acquire a rough texture. To make the design perfectly smooth and neat, the master must first coat it with one layer of varnish, wait until it dries. After that, using sandpaper, it will be necessary to process the resulting rough areas. At the end, the bench is again covered with a couple of layers of varnish.

- For wood processing (both decorative and protective), only high-quality and branded mixtures should be used. Fortunately, today the range of such formulations is huge and is in the public domain.

- Such designs of country benches, which are built around a tree growing on the site, are quite popular. This solution looks very original, and it is pleasant to rest in such conditions. If a bench is set up around a young tree, the craftsman must leave space for further growth. Otherwise, at some point, the overgrown tree will simply destroy the garden furniture.

- It is advisable to think carefully about the design of the future structure in advance. In order for the bench to harmoniously fit into the surroundings of the local area, it must correspond to it. For example, against the background of bright and colorful courtyard decorations, a dark Gothic bench with an aging effect will look strange.

All details should be in harmony with each other, creating a single aesthetic ensemble.

Beautiful examples

There are many options for how to make and arrange a comfortable bench for a summer residence or home interior. Here the master can let his imagination go free and build a model of absolutely any type.Often, home-made shops with thoughtful design look like a real work of art. Consider a few successful homemade products.

- The original benches, stylized in antiquity, look very unusual and rich. They can have an uneven back made of boards of different lengths, rough lines, and traces of abrasions. It is advisable to paint such a non-standard garden bench in a dark shade, to treat it well with a shiny, glossy varnish. The result is a beautiful design, as if it came from a fairy tale.

- If you want to put an attractive, but minimalistic wooden bench on the street, it is advisable to make it from perfectly flat and clearly sawn planks. The restrained design can be painted in classic white. It makes no sense to decorate such a shop with additional decorations. It will look strict, but stylish and modern.

- A wooden bench can be multifunctional. So, from well-processed wood, you can build a reliable structure with a folding seat, under which a niche is hidden for storing various things. This can be a handy children's store in which the child can store their favorite toys. Of course, in the manufacture of this design will be more complex and costly, but it will cope with several functions and simply decorate the suburban area.

- An unusual and solid bench will turn out if its supporting parts are built from 2 thick and strong stumps. Between them, you can install a wooden seat and backrest, which look slightly untidy, have uneven lines and a pronounced wood structure. The construction will turn out to be incredibly strong and durable.

It can be painted in your favorite color to decorate the local area.

For information on how to make a garden bench with your own hands, see the next video.

The comment was sent successfully.