Choosing a self-tapping screw for plywood

It is more convenient to fix plywood to the floor with self-tapping screws. This is a practical way to lay the finishing material. In addition, decorative finishing can be done in this way. Plywood sub-flooring has many advantages. And the choice of self-tapping screws affects the stability of the fasteners.

Self-tapping screws are special fasteners that are suitable for different types of flooring:

- wood (chipboard, plywood, glued veneer, solid wood);

- from drywall;

- metal (in the form of sheets).

The self-tapping screw is a threaded rod element with a head for easy and quick screwing. The choice of self-tapping screws will depend on the thickness of the material. The hardware itself is made of stainless steel, carbon steel or brass.

The most popular and affordable in financial terms are self-tapping screws made of carbon steel with different types of coatings.

Views

Hardware is successfully used when laying plywood on a wooden floor. Often, due to the loss of functionality, the wooden floor needs to be re-finished, for example, if it has dried out or has become unusable, has acquired a shabby appearance. Most often, self-tapping screws are used for this purpose.

Self-tapping screws can be classified by size (for example, 10 mm, 12 mm thick) and by type of thread. So, hardware can have:

- regular thread (perfect for a variety of coatings, for example, for fastening sheets of glued veneer);

- thread with a frequent pitch (if fastening is carried out to metal or to metal sheets);

- fine pitch threads (when you need to fasten on a soft material such as plastic or plywood).

For fastening interior items, the technology of special stacking of plywood sheets on screw hardware is used. To connect the material, a 7 mm by 50 mm confirmation is used. In order to screw in the screws, a number of holes are first made in the material (for example, these can be holes from 5 to 8 mm.).

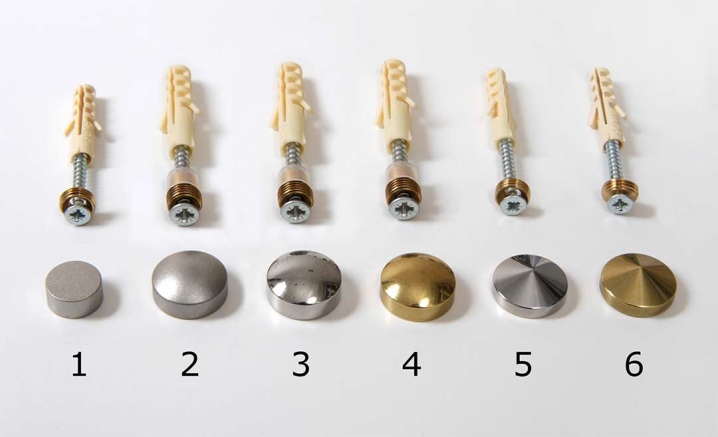

In order to "hide" the screw head and give the work a finished and aesthetic look, decorative overlays are specially used. They are matched to the color of the material.

As practice shows, hardware is effective for various types of repair work. Fasteners for hardware includes the following points:

- fastening plywood to a wooden floor on logs is performed if there are no deflections of the floor;

- for high-quality flooring using self-tapping screws, a work plan is being prepared;

- during installation, it is important to take into account the level of humidity in the room, so that, for example, in the bathroom, the floors do not swell over time;

- preliminary marking on plywood sheets will speed up installation work;

- using self-tapping screws, they are placed at a certain distance relative to each other, with an indent of at least 2 cm from the edges and with a step of 20 cm;

- when laying plywood on the floor with self-tapping screws, gaps of at least 1.5 cm are left;

- all laying elements from above must be “sunk” down to 2 mm.

When choosing hardware for laying plywood on the floor, the length and thickness of the connecting elements are taken into account, which should not be thicker than plywood.

The choice of self-tapping screws for plywood

Various options for repair hardware allow you to carry out the entire range of installation work.

- Roofing screws are distinguished by the presence of a hex head and are used on metal tiles and profiled sheets. The length of such self-tapping screws is from 19 to 100 mm with a rod diameter of 4.8 and 6.3 mm. Screw caps differ in color - from red and brown to green or white, depending on the shade of the roofing material.There are unpainted screws with a galvanized head or washer.

- Furniture screws - confirmat - are widely used in the furniture assembly process. The most common of them are up to 50 mm in length, taking into account the hex head. Before fastening, pre-drilling is required with a confirmation drill.

- Self-tapping screws called construction wood grouses. This name was given to hardware with a thick rod and a hex head. Fasteners are used when working with heavy structures for fastening complex assemblies and where additional reliability and strength are required. For example, this can be a gable roof structure or wooden rafter systems, as well as options for floors between floors. The thickness of the core of the self-tapping “wood grouse” can be from 6 to 10 mm with a hex head from 10 to 19 mm.

- Self-tapping screws when working with wood or plywood. They are used for fastening together with expansion dowels. You cannot do without such self-tapping screws in a private house or in an apartment. Hardware for fastening wooden materials have their own characteristics. They are characterized by the presence of a cruciform connector, a rare thread pitch, a sharp tip and a semicircular head. This type of self-tapping screws has no characteristic differences in the coating - they can be black, silver, yellow, white.

- Hardware for metal is distinguished by frequent carving and drill end. There are different types of self-tapping screws: "bug", hardware with black coating, zinc coated white or black. So, when fastening metal to drywall, self-tapping screws with a black coating are used. Cementation of the surface of the products makes the fasteners more reliable.

- There are options for concrete screws. No dowels are required to screw them in. It is worth considering that for screwing the hardware into the base, holes are drilled in the material with a diameter corresponding to the diameter of the fasteners.

Terms of use

Immediately before the fasteners, initial work is required:

- before laying plywood with hardware, the floor should be cleaned of dirt and dust, and thoroughly dried;

- for high-quality laying of sheets of plywood or other material, you will need to grind the base well;

- sometimes sandpaper is enough to go over the surface of the material (especially around the edges);

- for greater strength and reliability, the floor surface is treated with a special compound, primed - this will help to eliminate all microcracks;

- before the work itself, the material and pieces of flooring are laid out on the floor surface.

Today, many fixing methods for flooring are used in construction. Several factors affect the choice of the fastening system, including the quality of the material and the base. Hardware (or self-tapping screws) for plywood are used to ensure high-quality and reliable fixation of the material to the wooden floor.

The comment was sent successfully.