All about self-tapping screws "potay"

Self-tapping screws are a mandatory attribute to connect individual parts of one product or structure to each other. This fastener is used both in various types of production activities and in everyday life.

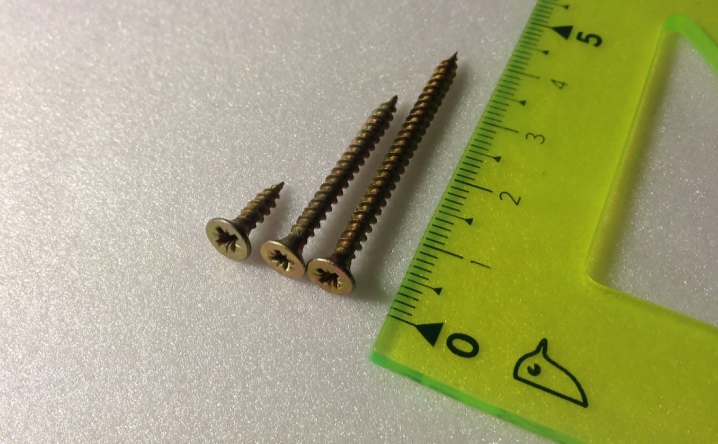

The assortment of self-tapping screws on the modern market is large and varied. Each species has certain technical parameters and properties. The most frequently used self-tapping screw with a countersunk head, its second name is "potay". It is about him that will be discussed in this article: we will define the features, types, sizes and scope.

Peculiarities

Self-tapping screws "potay" - it is one of the most commonly used types of fasteners... The main reason for this popularity is the presence of a countersunk head on the product. Its shape is so perfect that the working surface after mounting the self-tapping screw remains flat, without any bulges.

If you screw the self-tapping screw correctly, the head of the fastener will fit into the seat, and the plane of the material will have an aesthetic appearance.

Such fasteners have a number of other features, namely:

- strength;

- reliability;

- wear resistance;

- corrosion resistance;

- long service life;

- wide selection and assortment.

All self-tapping screws differ in size and purpose. There are fasteners designed for fastening wooden or plastic structural elements, there is also a separate type for working with metal.

The design of a self-tapping screw is practically no different from a conventional screw. It consists of:

- a rod, along the entire length of which the thread is located (sometimes the thread is applied only to a part of the product);

- slotted heads (the type of head is different);

- tip of a sharp or blunt type.

For the manufacture of a secret self-tapping screw, only high-quality, reliable materials that have good physical and technical properties are used.

It can be stainless carbon steel or non-ferrous metal such as brass. After manufacturing, the fasteners can be treated with a special coating that increases its anti-corrosion properties. Most often it is zinc or other phosphate substances.

The production process, control of the materials and raw materials used are clearly spelled out and provided in the regulatory documents GOST 1145-80, GOST 1144-80 and GOST 1146-80. Also, these regulations control the passage of all necessary laboratory tests and the issuance of quality certificates.

The product is characterized by the following parameters:

- screw diameter, mm;

- screw length, mm;

- slot size;

- type of thread;

- appointment.

Species overview

Given the popularity and wide scope of the product, it is not at all surprising that there is a wide selection of its types on the market. There are the following types of fasteners.

- With a drill. Another name is "self-drilling". Such self-tapping screws are used for roofing work.

For their manufacture, hardened steel is used, and white zinc is used as a coating.

- With a drill... Most often, such products are used for fastening metal structures.

A self-tapping screw is made of hardened or case-hardened steel, then coated with white zinc.

- Universal... This type of fastener can be used for absolutely any type of construction and installation work. It is characterized by strength and wear resistance. Threads can be full or partial.

For the production of the product, hardened case-hardened steel is used, the coating here is zinc.

It is also worth noting that each type of self-tapping screws can differ not only in purpose and size, but also in thread. It can be large, small and special.

Dimensions (edit)

The size range of the fastener is quite diverse. This allows you to choose exactly the product that is ideal for working with a particular material.

Detailed information and the most commonly used sizes of countersunk screws can be found by looking at the tables.

The size | Screw diameter, mm | Screw length, mm | Coating | Type of material |

2,5x20 | 2,5 | 20 | yellow zinc | wood, plastic |

2,5x25 | 2,5 | 25 | yellow zinc | wood, plastic |

3x10 | 3 | 10 | white zinc | wood, plastic |

3x30 | 3 | 30 | yellow zinc | wood, plastic |

4x45 | 4 | 45 | white zinc | wood, plastic, metal |

5x60 | 5 | 60 | yellow zinc | wood, plastic, metal |

6x60 | 6 | 60 | yellow zinc | wood, plastic, metal |

6x120 | 6 | 120 | white zinc | wood, plastic, metal |

6x200 | 6 | 200 | white zinc | wood, plastic, metal |

In specialized stores, you can also familiarize yourself with the full range of products in length.

When buying fasteners, it is very important to take into account both its size and other technical characteristics, including what material you need the fastener for drilling.

Experts recommend choosing fasteners only at special points of sale and giving preference to well-known brands and manufacturers.

Where are they used?

As mentioned above, the design features of the countersunk self-tapping screw contributed to wide application of the product in the process of fastening various elements:

- wooden;

- plastic;

- steel sheets (metal products).

To work with metal structures, use a self-tapping screw with a drill.

Most often, this fastener is used when working with wood. In the process of carrying out facade and roofing works, the potay self-tapping screw is an indispensable element. Its use makes it possible to securely fix the structure assembly and maintain its aesthetic, reliable appearance, smooth and even surface.

The video below briefly talks about the application and the difference between a self-tapping screw and a screw.

The comment was sent successfully.