Varieties and selection of wood screws

At the moment, the most common fastener for use in production and in everyday life is everyone's favorite self-tapping screw for wood. You should understand its varieties in order to choose the right one.

Peculiarities

The main advantage of such a self-tapping screw is that it is not necessary to pre-drill a hole - due to the sharp base and thread, they are independently screwed into the surface. This is a great alternative to nails.

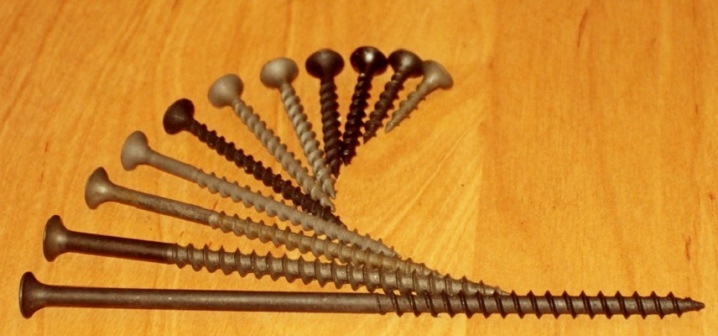

A self-tapping screw for wood visually differs from another type due to a rare thread (this helps the self-tapping screw firmly hook onto the wood fiber), its turns are more voluminous and deeper. Also, to get rid of wood chipping, it must have a very sharp needle-like base (tip). To hide such fasteners, and it did not stand out on the finished product, a conical countersunk head was made with a self-tapping screw.

The average length of a self-tapping screw for wood is 10-250 mm. If the length exceeds 80 mm, then the thread will not be for the entire rod - this will help reduce the resistance when screwing the self-tapping screw into the wood.

For each type of construction work, you can choose the right self-tapping screw. The choice is simply huge, this is due to the variety of materials used. But all of them must comply with GOST.

Comparison with self-tapping screws for metal

Since wood and metal have completely different structures, different self-tapping screws are used.

- The wood is less dense, fasteners with a large thread pitch are suitable for it - this way the fastened material will be securely fixed, and the wood fibers will be less damaged. Also for the installation of wooden structures, thinner self-tapping screws are used.

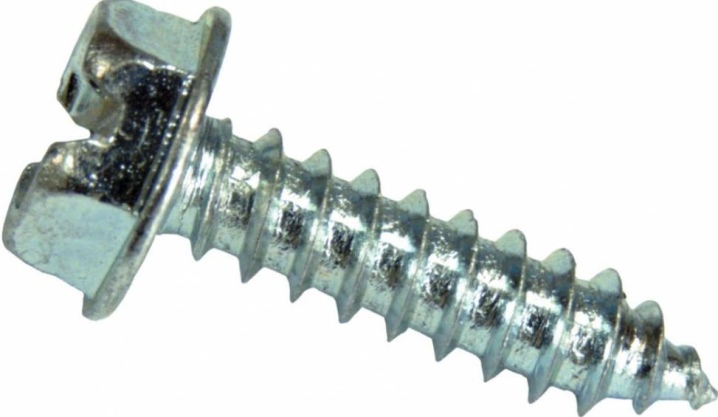

- The main difference between a self-tapping screw for metal is a smaller thread pitch, which ensures a high-quality connection of various metal structures and profiles. These screws are thicker and stronger.

Both self-tapping screws have very sharp ends, they can be made of identical materials and have the same caps.

At the moment, you can purchase a so-called universal self-tapping screw that will fit any type of material.

Species overview

Many are faced with this type of fastener for the first time and simply do not know how the wood screws differ among themselves. It is difficult for an inexperienced person to immediately navigate such a wide selection of varieties.

It is customary to classify product data according to several criteria.

Outside surface treatment

From what material the self-tapping screw will be made, its further strength depends. It can be stainless steel, carbon steel, brass. To protect it from corrosion, it is coated with a special solution.

If the self-tapping screw has a black color, then this is the so-called phosphated self-tapping screw. Used in places with low moisture levels, extremely unstable to corrosion.

Self-tapping screws covered with brass are yellow and are recommended for use in buildings with high humidity.

Another type of self-tapping screws is galvanized, in appearance they are white. They are used absolutely in any environment, attached to any type of wood.

The silver color is found in hardware covered with a chromium film. This coating prevents the development of corrosion, protects against abrasions and scratches. They are considered decorative, used wherever it is important not to disturb the aesthetic appearance of the room.

By form

Manufacturers offer the widest range of self-tapping screws. Under different operating conditions, fasteners of a certain shape are used, some of them have special options, for example, rubber gaskets or a surface in the form of a drill.

- Some of the best are structural screws. In fact, they are almost universal for woodworking, as they are suitable for various types of wood. They are made of strong and ductile steel, which allows them to be used in any bend (that is, at whatever angle it is screwed in, it will be very difficult to break it). A structural self-tapping screw is usually used when joining massive structures.

- With a press washer. Suitable for mounting plywood or thin profile sheets, equipped with a washer-shaped head that does not allow the self-tapping screw to go deep. Produced mainly in white and yellow colors. Anti-corrosion. There are also self-tapping screws with a painted press washer. They are used for mounting profiled sheets of various colors.

- With a hex head. Such a self-tapping screw is also called deaf, it is suitable for connecting strong solid structures. At the very base it has a sharpening, the cap is made for a hexagon. It is almost always reinforced, in terms of weight and thickness it exceeds standard self-tapping screws. A wrench is used for clamping. There are also self-tapping screws with a countersunk head, with a recess for a hex key.

- Roofing screws have a hex head and a rubber washer, which provides an additional elastic seal and closes the hole from excess moisture. Most often they come with a drill at the end.

- Hardware for furniture are called confirmations, they have a blunt end. In order to tighten them, you need a pre-prepared hole. Virtually non-corrosive, made of high quality steel. They are used to assemble furniture, allow you to assemble and disassemble a wooden product several times without damaging the fastener holes.

- There is also a galvanized self-tapping screw for woodwork, called a tenon groove. As the name implies, it consists of a spike and a groove that help to perfectly connect the vertical parts.

- From professionals you can often hear such names as "fleas" or "bugs". These are self-tapping screws, the head of which has a truncated cone. Due to this, they have the ability to drill through even metal. As a rule, they are produced in small sizes.

- Self-tapping screw with a ring, another name is a ring screw. Looks like a tightly tightened hook. Often used when fixing construction timber to the facade of a building. It is able to withstand a small weight, it is not recommended to use it for fragile things, for example, chandeliers. Made of hardened carbon steel, zinc plated on top. If a dowel is selected for it, then it should be level with the sections of the self-tapping screw.

- Self-tapping screw with a large wide head used for better adhesion of fasteners to wood, plus this will allow you to close the hole.

By thread type

Main varieties:

- self-tapping screw with a wide thread pitch, used for soft wood (MDF, chipboard, fiberboard), such fasteners are also used when joining drywall, plastic;

- small pitch (low thread) is suitable for mounting dense wood, hard plastic and even metal parts;

- A two-start thread (it alternates between a small and wide pitch) is ideal for joining materials that differ from each other in their density, for example, gypsum fiber and metal profiles.

But these are only the most common types. Now manufacturers produce self-tapping screws with modified threads, they have special grooves, sharp edges, a cutter at the tip of the thread, or special gear turns.

Dimensions and weight

In principle, when choosing the desired size of a self-tapping screw, you can always take a sample with you, but if this is not possible, then you should understand a little about the existing samples.

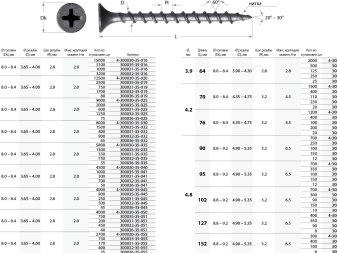

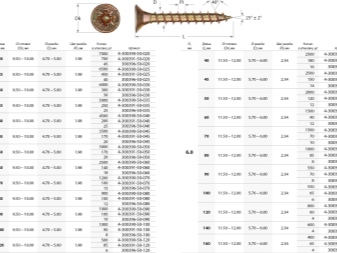

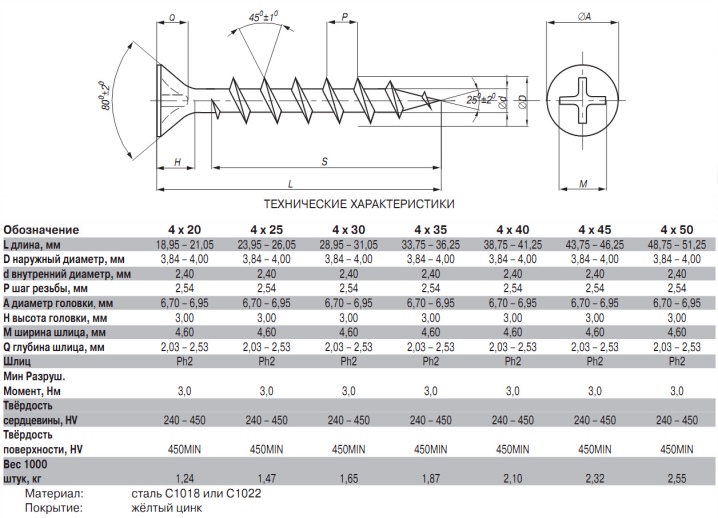

The parameters of the self-tapping screw are determined by the length and diameter:

- there is a standard range of fastener lengths: 10, 15, 20, 25, 30, 35, 38, 40, 45, 48, 50, 55, 60, 63, 70, 75, 80, 100, 120, 150 mm;

- the most commonly used self-tapping screws are universal, their standard parameters in diameter are 1.6, 2.0, 2.5, 3.0, 3.5, 4.0, 5.0, 6.0, 8.0, 10 , 0 mm.

These are standard sizes, but there are exceptions. The longest self-tapping screws reach 200-250 mm in length, they are designed to connect thick layers of wood. The smallest sometimes do not reach one centimeter.

And one of the most popular models of self-tapping screws (black) has a non-standard length of 51 mm, which does not in any way affect its general characteristics.

Experienced craftsmen first determine the thickness of the self-tapping screw, depending on its further use, they choose thinner or thicker ones. The next criterion is the length, someone will need a short one, and someone will not be able to do without a long self-tapping screw. Then refer to the diameter of the product. All self-tapping markings are very easy to read, and even the most inexperienced person will be able to decipher it. If the size of the package is 6x40 or 5x25, then the first value always indicates the diameter of the product, and the second - its length. Knowing this, it will not be difficult to choose the necessary fasteners yourself.

As a rule, manufacturers attach tables with the dimensions of their products, in them you can see how long the self-tapping screw can be and with what diameter of the cap.

By weight, the screws also differ. The mass of one hardware is with the parameters:

- 3.5 x 16 - 1.08 g;

- 3.5 x 19 - 1.13 g;

- 3.8 x 64 - 3.75 g;

- 3.8 x 70 - 4.73 g;

- 4.2 x 70 - 4.22 g;

- 4.2 x 76 - 4.79 g;

- 4.8 x 89 - 7.63 g;

- 4.8 x 95 - 8.58 g.

It should also be noted that the parameters for different brands may differ slightly, exceeding the 10% norm.

How to choose?

Of course, the most important thing is to decide on the purpose of using a self-tapping screw: why and where the hardware will be used, whether it will be affected by natural conditions (rain, snow). In addition, it is worth checking the quality of the screws you need.

- The hardware must be identical in color - this is direct proof that they are processed equally well and will serve exactly the same.

- There should be no difference in size either - visually, everything is the same length and thickness. The same applies to the thread pitch: the threads are clear and with the same cutting interval.

- If there are special drills at the end, there should be no burrs. The edge must be sharp, not broken off, otherwise such a part will automatically become unusable.

- The notch in the form of which the slot is made must be clear, deep and symmetrical.

- High quality self-tapping screws, as a rule, are marked with a special marking on the packaging - this is a capital Latin letter. Fasteners with such markings are produced in large factories and undergo additional testing and certification. By choosing high-quality products, you will not have to worry that the fasteners will break off at the most inopportune time.

Not having much experience in choosing hardware, it is better to consult a consultant or just an experienced craftsman. He will help you choose the right type of fasteners for a certain type of work or choose the color of furniture fittings.

Work rules

It is quite simple to use wood screws in work, especially if you have a screwdriver at hand, but even without an additional tool, using a suitable screwdriver, this task is easy to accomplish. In order not to damage the self-tapping screw during the screwing process and not to crush the wood, you need to adhere to some rules.

- When fastening a thin piece of wood or using brittle wood, special care is needed - one wrong movement can lead to a split of the material used. To avoid such a situation, a hole is made in advance for the self-tapping screw - it is also called a pilot hole. A wood drill and a drill are used for such work. The diameter is determined by the characteristics of the raw material.For example, if a softwood material is used, the drill bit should be half the diameter of the fastener. And when working with such a dense tree as oak, a drill is selected that is completely identical to the size of the hardware.

- Many people choose the length of the self-tapping screw, guided by the rule "more is better." It seems that a long hardware will hold it together more reliably, and if the part allows it, sometimes they drill it through with a self-tapping screw. But this opinion is wrong. Experts note that the correct length is the key to durable fixation. The self-tapping screw in length should be 6-7 mm shorter than the thickness of the fastened structures or parts.

- The situation is similar with the choice of the diameter. You do not need to choose the thickest self-tapping screw, because sometimes thin fasteners will cope with the task much faster and more efficiently. Also, it is much easier to work with thin hardware, and the ability to split the product is reduced to almost zero.

- There is a type of wood into which it is very difficult to screw a self-tapping screw, especially if only a screwdriver is used. Professionals recommend pre-lubricating the fasteners with laundry soap or wax - this will help to pass the hardware into the desired material.

- The basic principles of how to properly screw a self-tapping screw into a tree have already been considered. But what if such an old self-tapping screw needs to be removed? An ordinary soldering iron will help: you should hold it a little on the necessary fasteners, because everyone knows the fact that the metal expands when heated. After the screw cools down again, it will no longer be difficult to remove it.

For an overview of wood screws, see below.

The comment was sent successfully.