Features of self-tapping screws with a press washer and their application

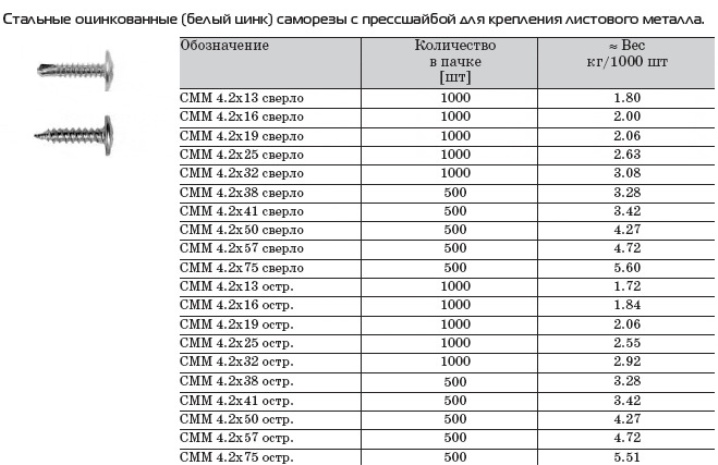

A self-tapping screw with a press washer - with a drill and sharp, for metal and wood - is considered the best mounting option for sheet materials. The sizes are normalized according to the requirements of GOST. Color, black, dark brown, green and galvanized white are distinguished by color. Finding out more about the areas of application, features and the choice of self-tapping screws with a press washer will be useful to everyone who is associated with the field of construction and building decoration.

Specifications

A self-tapping screw with a press washer belongs to the varieties of products used for metal work. Its production is regulated by the requirements of GOST 1144-80, 1145-80, 1146-80, for products with a drill tip, DIN 7981, DIN 7982, DIN 7983 are applied.

Officially, the product is referred to as "self-tapping screw with press washer". Products are made of ferrous or non-ferrous metal, most often on sale you can find a galvanized self-tapping screw or a roofing version with a colored cap.

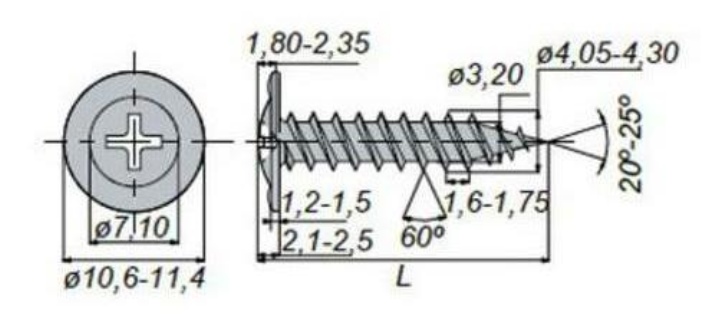

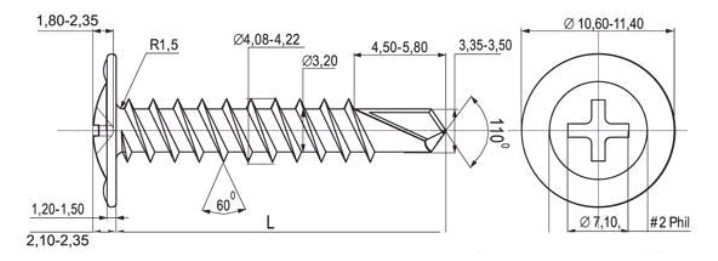

The main characteristics of this type of metal products:

- thread in the range ST2.2-ST9.5 with fine pitch;

- the bearing surfaces of the head are flat;

- zinc coating, phosphate, painted according to the RAL catalog;

- pointed tip or with a drill;

- cruciform slots;

- semicircular hat;

- material - carbon, alloy, stainless steel.

Black self-tapping screws with a press washer is used only for internal work. Galvanized and made from non-ferrous metals suitable for outdoor use. These products do not require preliminary drilling of a hole - the self-tapping screw goes into metal and wood, drywall and polycarbonate easily and quickly.

A screw with a press washer differs from other options in a greater downforce, an increased head area. A self-tapping screw of this design does not spoil the surface of sheet materials, excludes their puncture.

Views

The main division of self-tapping screws with a press washer into categories is based on the type of tip and the color of the products.

- The most widespread are white variants. with galvanized glossy coating.

- Black, dark brown, gray self-tapping screws - phosphated, made of carbon steel. The coating is applied to the metal, forming a film with a thickness of 2 to 15 microns. Such self-tapping screws lend themselves well to subsequent processing: painting, chrome plating, water repellency or oiling.

- Colored coatings are used only on caps. They are designed for roofing screws with a press washer, allowing you to make hardware less visible on the surface of the sheet material. Most often, screws with a head painted according to the RAL palette are used when installing corrugated board on facades and roofs of buildings, in the construction of fences and barriers.

- Self-tapping screws with golden press washer have a titanium nitride coating, are used in the most critical areas of work where high strength is needed.

Sharp

The most versatile type of self-tapping screws with a press washer can be called options with a pointed tip. They differ from their traditional flat-cap counterparts only in the shape of the head. The slots here are cruciform, suitable for use with a screwdriver bit or a regular Phillips screwdriver.

Products of this type are considered suitable for use in metal work with a thickness of up to 0.9 mm without additional drilling, and have proven themselves well for fixing wood-based panels and other materials.

When screwing into materials that are too dense and thick, the sharp tip is rolled up. To avoid this, it is sufficient to carry out preliminary boring.

With drill

A self-tapping screw with a press washer, the tip of which is equipped with a miniature drill, is characterized by increased strength and hardness. For its production, types of steel are used that surpass most materials in these indicators. These self-tapping screws are suitable for attaching sheets with a thickness of more than 2 mm without the need for additional drilling of holes.

There are also differences in the shape of the hat. Products with a drill bit can have either a semicircular or a hexagonal head shape, since noticeably greater forces are applied when screwing them in. In this case, when working with your hands, special spanner keys or bits are used.

Roofing screws also often have a drill bit, but due to the special requirements for anti-corrosion resistance, they are mounted complete with an additional washer and a rubber gasket. This combination avoids moisture penetration under the roof sheathing and provides additional waterproofing. On the painted profiled sheet for the roof, colored self-tapping screws are used, factory-processed to match the material.

Dimensions (edit)

The main requirement for the size of self-tapping screws with press washers is their compliance with standards for individual elements. The most popular product lengths are 13 mm, 16 mm, 32 mm. The rod diameter is most often standard - 4.2 mm. When these indicators are combined, a hardware marking is obtained that looks like this: 4.2x16, 4.2x19, 4.2x13, 4.2x32.

In more detail, the range of sizes can be studied using the table.

Applications

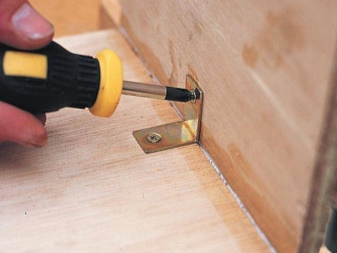

According to their purpose, self-tapping screws with a press washer are quite diverse. Products with a pointed tip are used to attach soft or fragile materials to a wooden base. They are suitable for polycarbonate, hardboard, plastic sheathing.

In addition, such zinc-free self-tapping screws are ideally combined with wood-based panels and building materials. They are used for fastening a drywall profile, creating cladding on partitions made of chipboard, MDF.

Painted roofing screws are used in combination with polymer-coated profiled sheet, their classic galvanized counterparts are combined with all soft materials, sheet metal with a smooth surface. It is necessary to screw in self-tapping screws with a drill bit with a special tool.

The main areas of their application:

- installation of metal lathing;

- hanging structures on a sandwich panel;

- installation and assembly of ventilation systems;

- fastening the slopes of doors and windows;

- formation of barriers around the site.

Self-tapping screws with a pointed tip have an even wider range of uses. They are suitable for most types of interior work, do not spoil even fragile and soft coatings, decorative elements in interior decoration.

Selection recommendations

When choosing self-tapping screws with a press washer, it is very important to pay attention to some parameters that are of the greatest importance in their subsequent use. Among the useful recommendations are the following.

- White or silver color hardware indicates that they have an anti-corrosion zinc coating. The service life of such screws is as long as possible, calculated in decades. But if work on metal is coming, you should definitely pay attention to its thickness - the sharp tip will roll over at a thickness of more than 1 mm, here it is better to immediately take the option with a drill.

- Painted self-tapping screw with press washer - the best choice for installing roofing or fence coverings. You can choose an option for any color and shade. In terms of corrosion resistance, this option is superior to conventional black products, but inferior to galvanized ones.

- Phosphated hardware have colors from dark brown to gray, depending on the characteristics of their processing, they have a different degree of protection from the influence of the external environment. For example, oiled ones receive increased protection against moisture, they are better stored. Phosphated products lend themselves well to painting, but are used mainly for work inside buildings and structures.

- The type of thread matters. For self-tapping screws with a press washer for metal work, the cutting step is small. For woodwork, chipboard and hardboard, other options are used. Their threads are wide, avoiding breaks and twisting. For hardwoods, hardware is used with cutting in the form of waves or dashed lines - to increase the effort when screwing into the material.

Considering all these factors, it is possible to choose suitable self-tapping screws with a press washer for performing work on wood and metal, fastening fences from a profiled sheet, creating roofing coverings.

You will learn how to choose the right screws with a press washer and not purchase a low-quality product in the next video.

The comment was sent successfully.