Variety and use of self-tapping screws for metal

Strong and durable construction is the result of the use of quality fasteners. Currently, consumers are in special demand bolts for metal, which have many advantageous characteristics. They will be discussed in our article.

Peculiarities

Self-tapping screws of this type are used not only in everyday life, but also in production. Since metal has a rigid structure, only this category of hardware can handle it. These fasteners have a low cost and are sold in kilograms or by the piece. There are usually few parts to complete a task, so the purchase is often made by weight.

The main feature of metal hardware is the presence of a sharp end or a tip with a drill and fine-pitch thread.

The main characteristics of the products are:

- low cost;

- no difficulties in the installation process;

- wear resistance;

- good quality and long period of use;

- resistance to negative environmental factors.

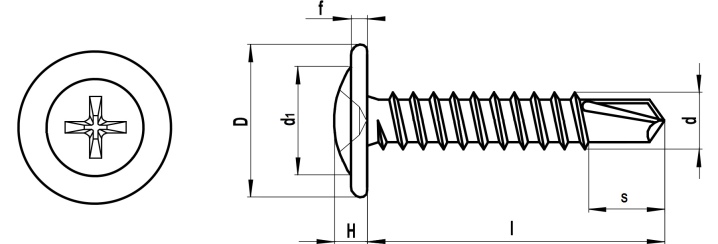

The bolt for fastening metal structures consists of several parts.

- The rod is the main part of the self-tapping screw, which has a significant length and different pitch.

- Head. According to the peculiarities of the application, this hardware can have a head for a hex key or for a Phillips-type screwdriver.

- Washer or gasket that seals the hole. Most manufacturers sell self-tapping screws with a rubber gasket. However, they are not durable and reliable enough. The washer must have a convex shape, which contributes to increased tightness during installation.

- Tip. This part of the product is characterized by its tightness and drill-like shape.

During the manufacture of self-tapping screws for a metal sheet, the manufacturer must be guided by GOSTs 1144-80, 1145-80, 1146-80, DIN 7981, 7982, 7983.

Compliance with these standards allows the use of products when joining surfaces inside and outside the premises.

Applications

Self-tapping screws are actively used to connect sheet polycarbonate, thick and thin materials. They are used in various repair areas, construction sites and for solving everyday problems. The popularity of fasteners for metal is due to the reliability of fasteners and ease of installation.

This type of parts is needed for fastening structures, organizing industrial and production facilities. It is difficult to do without this device in the process of installing a roof to a metal structure or wooden crate. With the help of some models, wood, plywood or chipboard is fixed to the metal profile, without first making holes in the material.

Species overview

Self-tapping fasteners are of different types, thanks to which you can always find the right option for a particular job. Black and colored products can look different and have different purposes:

- decorative;

- roofing;

- for drywall;

- for metal profiles of different thicknesses.

The thread of these products can also be different.

- Large Is a high thread that has a wide pitch. Such parts are often held together by soft and loose materials.

- Small - low with a narrow step. Such products connect a dense and hard surface.

- Two-way, which has both high and low turns, which alternate with each other.This fastener is considered the best option for fastening materials of different characteristics.

The craftsman can buy a self-tapping screw, a galvanized drill bit, or a fixture with a thermal washer.

Often on sale there are reinforced hardware for a hexagon and a screwdriver. You can find out about the characteristics and purpose of the bolt thanks to the marking.

By head type

Usually with self-tapping screws for metal semicircular and cylindrical headsalso meet options with hex or ball head. Metal products with hex heads are currently considered the most common, since they do not require a lot of time and effort during work. Also, the master can purchase products with rounded, countersunk, trapezoidal heads, as well as press washers and EPDM gaskets.

By slot type

The slot for hardware fixing metal surfaces can be of the following types:

- anti-vandal;

- Torx;

- Ph;

- Pz.

By tip type

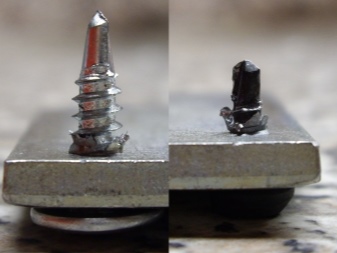

According to this criterion, self-tapping screws are pointed and with a drill. The former are characterized by the presence of a pointed tip and a rolled thread. It can be used when working with metal, the thickness of which does not exceed 0.9 mm.

On the head of such a product, a press washer may or may not be present.

The second version of the fastener has pointed drill with two feathers at the end. With the help of this product, metal is fixed, which is more than 2 mm thick. Hardware with a drill is used for mounting the internal and external parts of the product. Their reliability is ensured by a zinc coating and a painted head.

By type of coverage

The coating of self-tapping screws for metal can be different.

- Phosphated... In this case, the fixing bolt is colored black. Such hardware is made from carbon steel, after which it is treated with phosphates. Often, such a product is used in a room where there is high humidity.

- Oxidized... The element is painted black and, as in the previous version, is made of steel, on which an oxide film is applied. The oxidized self-tapping screw for metal is used in a room with an optimal level of humidity.

- Galvanized... The material for the manufacture of metal products is low-carbon steel, which is coated with zinc. This type of fastener can be used in any conditions.

- Galvanized yellow. These products are distinguished by their color, they are often used for fixing doors and for other decorative purposes.

Also on sale you can find models for fixing metal surfaces that do not have any coating.

They can only be used during interior work and under normal indoor humidity conditions.

Standard

Hardware quality regulated by GOSTs, the main of which is 1145-80. According to this standard, metal products can have a countersunk head and a different type of slot. If the product is manufactured strictly in accordance with GOST, then it can be used in industry, production and construction. Such screws are made from carbon steel, stainless steel.

Goods that are made according to DIN 7981 and DIN 7982, are able to bond thin sheets of metal. However, it is recommended to re-drill the surface before carrying out the procedure. Products with shape C have a sharp tip, and those with shape F have a blunt tip.

Self-tapping screws DIN 7982 are made of steel, they differ little from products that are made according to GOST 10621-80 and ISO 7049... They have found their application in the machine-building and instrument-making industries.

Materials (edit)

To interconnect metal sheets, manufacturers use different materials for the production of such parts.

- Carbon steel, which is an alloy of iron and carbon. In this case, impurities are not used, therefore the products are characterized by high strength.

- Stainless steel... The material for the manufacture of self-tapping screws for metal contains more than 10.5 percent chromium.Due to this feature, the product is characterized by corrosion resistance and a long period of operation. Stainless steel fasteners are environmentally friendly and hygienic, so they have found their application in the medical field.

- Brass... This alloy consists of copper combined with zinc, in some cases the manufacturer can add tin, nickel, lead, manganese. Brass fasteners are reliable and durable products that are resistant to temperature changes and have magnetic properties.

Dimensions (edit)

It is worth choosing self-tapping screws with special responsibility, while it is important to take into account the following rules:

- the length of the threaded part should be selected in such a way that it is greater than the total thickness of all materials to be joined;

- buying too long fasteners is considered irrational, since their length directly affects the cost of hardware;

- the craftsmen claim that the optimal length will be the tip that goes through the materials.

To learn more about the sizes of the smallest and largest self-tapping screws for metal with a sharp tip, the table will help:

Marking | Length | Head diameter, mm | Press washer diameter, mm | Int. Base diameter, mm | Base outer diameter, mm | Weight, kg per 1000 pieces | |

4, 2*13 | 13 mm | 7,1 | 10,6–11,4 | 3,2 | 4, 05–4,3 | 1,66 | |

4,2*14 | 14 mm | 7,1 | 10,6–11,4 | 3,2 | 4, 05–4,3 | 1,73 | |

4,2*16 | 16 mm | 7,1 | 10,6–11,4 | 3,2 | 4, 05–4,3 | 1,89 | |

4,2*19 | 19 mm | 7,1 | 10,6–11,4 | 3,2 | 4, 05–4,3 | 2,04 | |

4,2*25 | 25 mm | 7,1 | 10,6–11,4 | 3,2 | 4, 05–4,3 | 2,45 | |

4,2*32 | 32 mm | 7,1 | 10,6–11,4 | 3,2 | 4, 05–4,3 | 2,87 | |

4,2*41 | 41 mm | 7,1 | 10,6–11,4 | 3,2 | 4, 05–4,3 | 3,6 | |

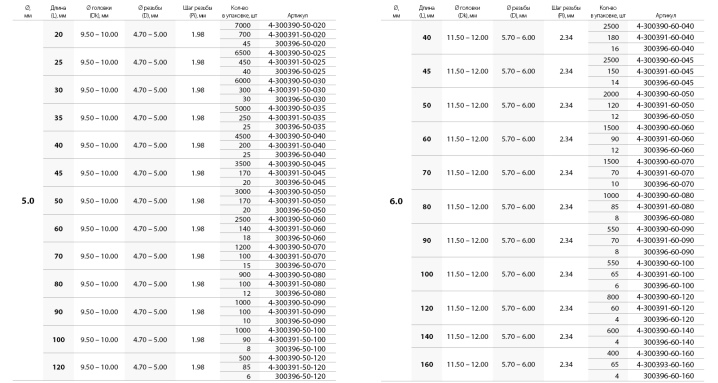

Size table of self-tapping screw for metal with a drill:

Marking | Length | Press washer diameter, mm | Int. base diameter, mm | External base diameter, mm | Drill length, mm | Drill diameter, mm | Weight 1000 pieces, kg |

4,2*13 | 13 mm | 10,6–11,4 | 3,2 | 4,08–4,22 | 4,5–5,8 | 3,35–3,5 | 1,85 |

4,2*14 | 14mm | 10,6–11,4 | 3,2 | 4,08–4,22 | 4,5–5,8 | 3,35–3,5 | 1,87 |

4,2*16 | 16 mm | 10,6–11,4 | 3,2 | 4,08–4,22 | 4,5–5,8 | 3,35–3,5 | 2,05 |

4,2*19 | 19 mm | 10,6–11,4 | 3,2 | 4,08–4,22 | 4,5–5,8 | 3,35–3,5 | 2,26 |

4,2*25 | 25 mm | 10,6–11,4 | 3,2 | 4,08–4,22 | 4,5–5,8 | 3,35–3,5 | 2,61 |

4,2*41 | 41 mm | 10,6–11,4 | 3,2 | 4,08–4,22 | 4,5–5,8 | 3,35–3,5 | 3,05 |

How to choose?

Among the wide variety of self-tapping screws for a metal sheet, it can be difficult to find a high-quality and suitable one for a specific task. So that the hardware does not disappoint, it is worth examining it carefully and clarifying the details.

- The color of the product must be uniform. If the entire batch of bolts has the same black or yellow color, then this means that each product has undergone the necessary processing and meets high strength and reliability indicators.

- The dimensions of each unit of the consignment must be the same, that is, there should be no visual differences between the hardware.

- The pitch between the turn threads must be equal everywhere.

- Pointed bolts should be free of burrs and breakage at the end.

- For good quality self-tapping screws, the first letter on the marking is always capitalized. This moment indicates that the parts were manufactured in production.

A self-tapping screw can be considered of high quality if it was produced strictly in accordance with GOST, and also used metal with good characteristics in the manufacturing process.

Experts recommend buying bolts from well-known companies and only from a trusted supplier., otherwise, there is a possibility of purchasing a poor bonding product.

How to use?

Self-tapping screws used to fasten metal structures, able to withstand enormous loads. In order to avoid cracking, sagging, breakage of hardware, you will need to learn how to tighten them correctly. Before screwing the fasteners into the metal part, the material should be cut correctly. Markup surfaces can be made with a center punch. If you need to work with a drill, then it should be installed perpendicular to the metal plate.

If the hardware has a sharp tip, then you should not make a hole in the material in advance. To screw a different type of self-tapping screw, the master will need to make a hole in advance, the dimensions of which will be slightly less than the diameter of the fastener rod.

During the installation of self-tapping screws, craftsmen should maintain a distance that should not exceed 40-50 centimeters.

When fixing the roof or covering the corrugated board to the masters it is allowed to apply light blows with a hammer on the bolt... Thanks to this type of fastener, you can make strong and reliable structures that can withstand a heavy load.If the screws for metal sheets are selected correctly, then the fasteners will hold out for a long time. Since this product is not a rarity, when choosing it, you should be extremely careful not to buy a fake.

When buying hardware in a store, you should ask the seller certificate on their quality. Experts advise using the parts strictly for their intended purpose. For example, do not fasten wood with hardware for working with metal. If you need to combine two different materials, then in this case, they are the best fit universal screws, which are able to hold together soft and hard raw materials.

For an overview of metal screws, see below.

The comment was sent successfully.