Dimensions of wood screws

When carrying out repair, finishing and construction work, as well as in furniture production, special fasteners are used - wood screws. What are their sizes and how to choose the most suitable one - read the article.

Standard

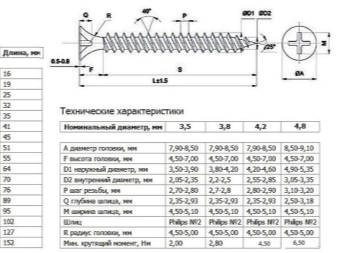

Sizes of universal screws are measured in two quantities - length and diameter. Their shank has an incomplete screw thread and less self-tapping characteristics.

The dimensions of wood screws are measured in accordance with GOST 1144-80, 1145-80, 1146-80.

Dimensions of different types

For working with wood, fasteners with rare threads are used. It is this structure that helps do not damage fastened parts. Also, craftsmen sometimes coat the material with oil for easier screwing and to reduce the destructive effect on wood. There is also a two-start or variable thread pitch - it is used for materials with a dense structure. In hard and dense wood, almost always holes for self-tapping screws are drilled in advance. This is done to make the process go faster. For the soft type, there is another reason: if the fasteners are installed close to the edge, the prepared hole will prevent the material from cracking.

The materials for making self-tapping screws are carbon steel, stainless steel and brass. Fasteners made of carbon steel are more popular, they have a low price and, with the right choice, will last for a long time. After a certain type of processing, the hardware acquires its own color.

- Black... Obtained by the oxidation process - this is a redox reaction, due to which an oxide film remains on the surface of the product, or by the process of phosphating, when a layer of poorly soluble zinc, iron or manganese phosphates is created on the surface.

- Yellow - obtained during the anodizing process, this is an electrochemical reaction, during which an oxide film forms on the surface.

- White - these are galvanized hardware.

By the type of end, fasteners are sharp or with a drill... Sharp ones are designed for soft materials, and those that have a drill are for denser materials or for metals thicker than 1 millimeter. There are also hardware and without ending, used in the assembly of furniture. Dimensional parameters of fasteners depend on the type and size of the fastened parts. The size chart is very large and includes more than 30 types. The length of the products varies from 13, 16, 20, 25, 30, 35, 40, 45, 50, 60, 70, 80, 90, 100, 110 and up to 120 mm. External screw thread diameters in millimeters - 1.6, 2.0, 2.5, 3.0, 4.0, 5.0, 6.0, 8.0 and 10.0.

The self-tapping screw should be as long as possible so that it can go through the first part and go into the second at least one quarter (or more) of its thickness. Such a mount can be called reliable. The smallest self-tapping screws for wood are also popularly called seeds, since their shape resembles sunflower seeds. Self-tapping screws for fastening drywall profiles are small fasteners, for their size they are called "bugs". Produced galvanized with cross recess. On the back of the head there are grooves for braking the screwdriver. The size of the diameter is 3.5 millimeters, and the length of the rod is 9.5 and 11 millimeters.

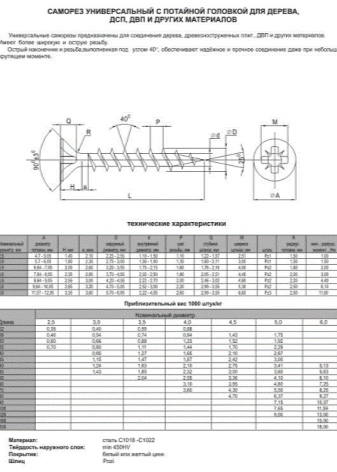

Countersunk head and straight slot

Used for parts that must fit snugly together. It is not necessary to pre-drill the grooves, since the special shape of the head allows the hardware to completely "enter" the tree.The recess for the tool on the head is a slot. It can be straight, cruciform, anti-vandal, hexagonal.

They are used in the manufacture of furniture and for sheathing.

Yellow and white cross recessed

Yellow and white (otherwise colored) self-tapping screws are used for fixing various parts to wood with preliminary preparation of holes. Resistant to the corrosion process. For production, soft steel is used, finished products are galvanized. The self-tapping screw has a sharp end and a countersunk head. Most often, door fittings are attached with these hardware.

Hex head

Very similar to a standard bolt, features a wider thread pitch and a sharper end... For screwing, keys of 10, 13 and 17 millimeters are used. Mainly used when working with material for the roof, for fixing any details on the fence, etc.... Hex fasteners are usually equipped with special rubber gaskets for sealing.

With press washer

Their main difference is a wide and flat head, along the edge of which there is a special protrusion for better clamping of parts... It has a fairly wide range of applications, suitable for metals, plastic, plywood, fiberboard. The dimensional grid of hardware with a press washer is small, all have the same diameter - 4.2 millimeters. The length ranges from 13, 16, 19, 25, 32, 38, 41, 50, 57 to 75 millimeters. Very often there are low quality self-tapping screws on the market. You can distinguish them by the cap - it is rounded and almost flat in shape, respectively, the slot is shallow. The metal of such products is not processed in any way and may bend or break during operation. Even self-tapping screws with a zinc coating quickly deteriorate and corrode, since the galvanized layer is very thin. Also, the size of the diameter of such fasteners can be 3.8–4.0 instead of the declared 4.2.

High quality self-tapping screws are an order of magnitude higher. Their cap is made in the form of a trapezoid and has a deep, pronounced slot. They can also be called reinforced. These hardware transmit the torque much better.

How to choose?

When choosing self-tapping screws for wood, do not dwell on metal or universal fasteners. Narrow-profile hardware will hold together a wooden structure better, and universal ones are optimal for joining metal and wooden surfaces. First you need to choose the type of screw head, the main point here is the connection to be made. Further, the type of slot. The most popular head recess types are TORX. They take the best torque from the tool.

Thread type - all over the screw rod or not. To connect two wooden parts, hardware with an incomplete thread is suitable. The length should correspond to the size of the element to be screwed on. There is a zone without threads under the head, and thanks to it, there is a tight fit of materials to one another. To facilitate screwing into dense wood, it is recommended to take fasteners that have a mill or mill. Only hardware with incomplete screw threads is equipped with it. It consists of several grooves located at the beginning of the thread. They help to "soften" the wood surface.

It is imperative to pay attention to the size of the diameter and length of the screw rod in order to prevent cracking of the wood during operation. An important point is where the thread originates from, it should be from the very end. A loop located far away indicates that the end is not pointed and blunt. Working with such fasteners will bring a lot of problems.

The choice of color also depends on the material with which you will work. For wood, yellow self-tapping screws are best, but they have a higher price. Black fasteners have a number of disadvantages: they are susceptible to corrosion, and stains can occur on the wooden surface. This is not so critical for metals, because the bond can be painted over.Also, black hardware is quite fragile - if you twist them, the hat may break off. An example would be flooring. Boards tend to dry out and bend, because of this, the load on the self-tapping screw increases, the head breaks off. Therefore, the wooden floor starts to creak.

If there is metal material in the connection, zinc-coated self-tapping screws will do. It is also worth considering how the hardware will be screwed into the prepared hole or not.

For information on how to choose the right self-tapping screw for wood, see the next video.

The comment was sent successfully.