Everything you need to know about workbenches

Workbenches are used to equip garages, car services, various small and large workshops. They come in different types. They are classified depending on the purpose, design, material of manufacture. Each model has certain features that you need to familiarize yourself with before purchasing a product.

What it is?

A workbench is a workbench designed to perform a wide range of tasks. The design is indispensable for:

- sharpening, cutting, assembling and disassembling parts;

- bending of metal products;

- soldering parts;

- work with wood.

Most models include not only a work surface, but also accessories for it. These can be pedestals, open and closed shelves, boxes - they are designed to accommodate hand tools, milling cutters, electrical equipment, various fasteners and parts. Workbenches help to organize the workspace of the locksmith, carpenter, electrician and garage owner. Having installed such a design, professional craftsmen and car owners will be able to conveniently store the accessories necessary for work.

Requirements

Equipping the premises with workbenches helps to accelerate the productivity of foremen, as well as creates a more comfortable and safe working environment for them. Comfortable products must meet a number of requirements:

- have sufficient strength and reliability to withstand the loads that the work of the master assumes;

- differ in functionality - the workplace should include shelves or boxes for storing tools;

- be ergonomic - the height of the working surface and its area must correspond to the growth of the employee and his needs;

- have good stability in order to remain motionless under power loads.

An industrial or household workbench must be durable. Quality products made of durable materials are capable of maintaining functionality for 10-50 years.

Views

The arrangement of a workshop, production workshop or garage must be approached with special attention. In this case, the crucial moment is the choice of layout. In order not to be mistaken in purchasing the optimal model, you need to study the advantages and disadvantages of all their types. Workbenches can differ in many ways, each of which must be taken into account.

By material of manufacture

Work surfaces are wood or metal. Products made from natural wood are most often made with their own hands, branded models are rarely found on sale.

Wooden workbenches are made in whole or in part from wood. Hardwoods such as beech or oak are suitable for their production. Fastening of structural elements is carried out using self-tapping screws, stability is achieved due to additional spacers.

The advantages of wooden models include:

- practicality;

- cheapness;

- functionality.

Wood products have significant disadvantages. These include the inability to withstand serious mechanical loads, limited service life during intensive operation, fire hazard. The working wooden surface quickly loses its external aesthetics in case of accidental spillage of dyes, solvents, oils.

Metal workbenches, in contrast to wooden ones, are distinguished by complex assembly and a higher price. However, these disadvantages compensate for the weighty advantages:

- durability - subject to the rules of operation, the product will last 20-50 years;

- multifunctionality - various electrical equipment can be installed on metal tabletops, as well as various types of work can be performed on them (including turning, metal cutting, grinding);

- strength - the working surface is resistant to deformation under various types of mechanical stress.

Metal work surfaces are easy to clean and do not require additional corrosion protection. Such workbenches are made by domestic and foreign manufacturers in a wide range. On sale there are both universal products and models with a narrow specialization.

By size and weight

Workbenches differ in terms of weight and dimensions. When making with your own hands, the parameters are selected independently, taking into account personal preferences and needs. And also some companies are engaged in the manufacture of work surfaces to order, taking into account the area of the installation site in the room.

There are averaged sizes:

- length - 1.2-1.8 m;

- width - 0.7-1 m;

- height - 0.75-1 m.

On sale there are mini-workbenches designed for the work of one person. Their length usually does not exceed a meter, and their width ranges from 0.7 to 0.9 m. As a rule, these are portable portable models that can be moved without much effort from one place to another. Most of these solutions weigh up to 50 kg.

Industrial large and heavy workbenches are also available - they are designed to accommodate an oversized power tool, the simultaneous work of several people. The length of such models can reach 6 m, while their width should be at least 1 m. The overall metal structures have a large weight, reaching several hundred kilograms.

Most heavy workbenches are stationary models - they must be fixed to the wall surface using special fasteners. Large workbenches are often equipped with protective screens, and also provide many additional places for storing tools.

By construction type

There are many designs and configurations of workbenches. In shape, the working surfaces are straight, angular and U-shaped. The first ones are designed to be installed near any of the walls of the room. Corner models are placed in the right or left corner of the workshop - this arrangement saves valuable space. U-shaped, due to their large dimensions, it is advisable to install in spacious rooms.

Workbenches are:

- bestumbovy;

- single-pedestal;

- two-block;

- three-bollard

The best-stand structures are provided with supports - legs. They are also called pendants. Depending on the model, the legs of the workbenches are adjustable in height, removable, stationary or folding. Some non-stand models have a shelf under the work surface for storing small items.

Single-pillar variations have one pedestal located under the table on the right or left side. These can be models with a drawer and hinged door or variations with drawers. The single-bollard workbench is compact, making it ideal for use in confined spaces.

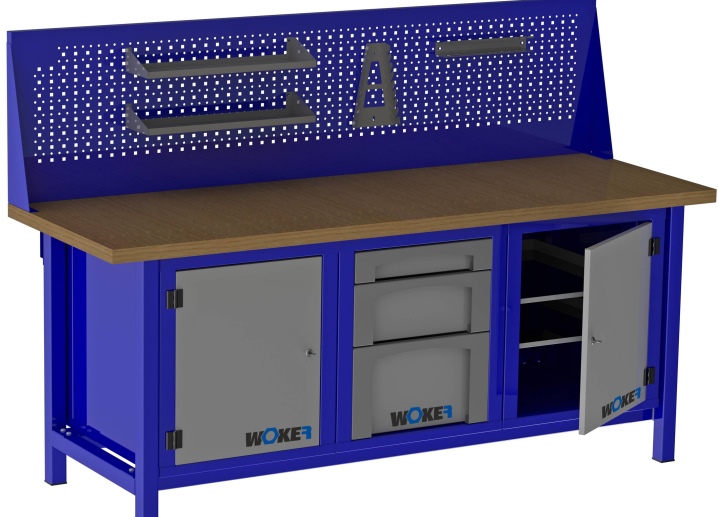

In two-pedestal models, the working surface rests on 2 pedestals located on opposite sides. Between them there is a shelf or a special partition that reinforces the structure. A three-pedestal workbench looks the same as a two-pedestal workbench, only it consists of 3 drawers on which the tabletop rests.

Drawers can be equipped with drawers. They are equipped with partitions dividing the space into parts, it is convenient to store fasteners, hardware, various small parts in them. Some models of workbenches have screens - these are vertical panels located along the entire length of the tabletop.They have holes for fixing the tool. It is easy to install shelves, various holders and hooks on the perforated screen.

Besides, workbenches are prefabricated - these models provide for the installation of various parts of the structure with a threaded connection. Sometimes there are wall solutions on sale. They are made in the form of a corner board, equipped with legs or corner stops, which reduce the risk of breakage under the influence of power loads.

By appointment

Workbenches are produced for various types of work. For example, joinery workbenches are made for wood craftsmen. These are mainly wooden models. Professional products can be single or double. They are equipped with a transverse or longitudinal vice.

There are special holes on the working surface of the joinery worktops for installing stops.

Workbenches are locksmiths. These are metal assembly or stationary structures designed for the arrangement of professional auto repair shops or private garages. They are equipped with sturdy 3-sided table tops. Locksmith's workbenches are equipped with tool boxes, shelves or racks.

Another popular model of the workbench is for a miter saw. Visually, such a product looks like a construction goat. In its center there are fasteners for installing the saw. Most of the variations offered by manufacturers are equipped with retractable stops. Thanks to them, it is possible to increase the length of the table for cutting dimensional boards.

On sale there are universal multifunctional workbenches. They are made of metal and can be disassembled. These work surfaces are suitable for an electrician, welder, milling machine operator. They can be equipped with an automatic drilling machine, electrical equipment, vice and other tools.

Combined workbenches are popular. They can be used by both joiners and locksmiths. The versatile work surfaces are comfortable to work with metal parts and wood blanks.

There are also rare models of workbenches for which there is limited demand:

- pipe structure - equipped with a chain clamp and pipe supports;

- workbench vise - a collapsible structure, the tabletop of which is divided into 2 equal parts - movable and fixed;

- tripods - portable models designed for reliable fixation of products with a large length.

For the storage of expensive equipment and tools, vandal-proof workbenches have been created. These models are more durable and reliable. In their design, hinges and locks are provided, designed to protect drawers and nightstands from burglary. To increase the mobility of vandal-resistant products, they are equipped with wheels.

Top manufacturers

Reliable, practical and durable workbenches are made by many companies. Several firms are classified as the best domestic producers.

- Verstakoff. The company is engaged in the production of metal workbenches, garage storage systems, shelving and other equipment. They offer ready-made solutions and are engaged in the production of products to order. Workbenches under this trademark, depending on the model, can withstand loads from 200 to 3000 kg.

- "Practitioner". He is engaged in the manufacture of carpentry workbenches intended for work in industrial production, in training workshops or garages.

- "Anchor". Folding work benches and support tables are produced under this brand. Products are designed for woodworking, are affordable and easy to use.

- "Master". The company has been known to domestic consumers since 1996. We offer compact tool benches equipped with a perforated back panel.

- "Bison". Domestic manufacturer of tools, shelving and other storage systems for garages.Under this trademark, wooden and combined workbenches for joinery work are produced.

The best foreign manufacturers of workbenches include the following companies: AEG (Germany), Ryoby (Japanese manufacturer), Bosch (Germany), Stayer, owned by the German concern Kraftool GmBH.

Criterias of choice

The stores offer a huge assortment of different types of workbenches, which is why it is sometimes difficult for the consumer to make the right choice. When buying a work surface, first of all, you need to decide on the size - the dimensions of the product are selected taking into account the free space in the room. If space permits, you can look at stationary professional models with numerous storage spaces. Due to the large area of the tabletop, most of the existing tools can be installed on it.

If you need a professional workbench, it is recommended to take a closer look at products with outlets - they will provide power to electrical equipment without the need for an extension cord. Similar workbenches can be purchased for a regular garage. If the area is small, it is advisable to give preference to simple single workbenches with a shallow depth. And also in this case, solutions with an angular configuration are suitable.

When choosing a workbench, you need to take into account its maximum permissible load. Serial models can withstand a load of 200-500 kg. Reinforced structures are capable of withstanding power loads of the order of 1500-3000 kg.

When choosing a workbench for an apartment or a summer residence, you should give preference to compact wooden models. It is best if they provide space for storing tools. A portable workbench without a bench can be taken out on the street or on the balcony. Such products will easily fit in rooms with limited space.

How to use?

Before starting work using a workbench, it is important to change into non-marking clothing and familiarize yourself with the safety rules of the electrical tools used. Correct use minimizes the risk of damage to the table.

Make sure the table is level before placing the tool on the work surface of the workbench. For these purposes, you can use a special device - a hydro level. Then you should make sure that the workbench does not wobble. To do this, you need to press on its corners.

If it is found that the working surface is wobbling, you need to move the product or put metal plates under the supports. In this case, it is not recommended to use paper, cardboard or wooden covers.

In addition, you need to make sure that the machine tool is firmly pressed against the table top. For a tighter fit between the vise and other benchtop tool, use a wrench. After carrying out these activities, you can start working.

In order for the workbench to serve as long as possible, it should be cleaned immediately after completion of work. After use, the tabletop must be wiped with a damp cloth, cleaning it from metal shavings and wood waste. Thanks to timely cleaning and adherence to the recommendations for use, the workbench will retain its functionality and aesthetics for many years.

We invite you to watch a great video review of workbenches.

The comment was sent successfully.