All about end cutters

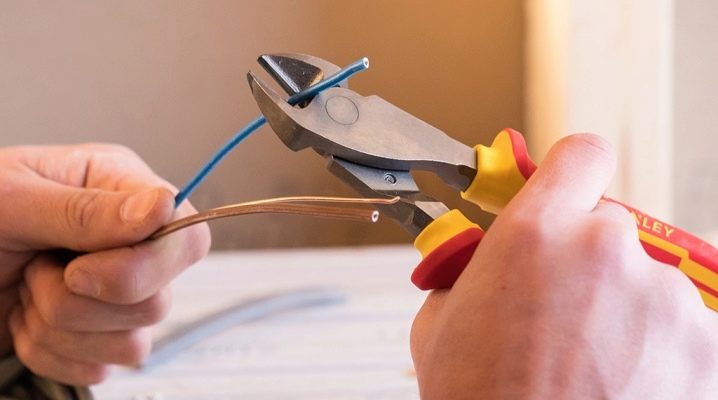

Nippers (or needle-nose pliers) are specialized construction tools designed for cutting various types of materials. There are several types of cutters on the construction market: side (or side cutters), reinforcing (bolt cutters), and end cutters. It is about this subspecies of needle-nose pliers that we will talk about today. From our material, you will learn the principle of the structure of the instrument, the area of its use, as well as the rules for selection.

The principle of structure

Any nippers (regardless of the type, manufacturer and material of manufacture) consist of two main elements:

- handle (thanks to it a person has the opportunity to work with the tool);

- cutting parts (usually called sponges).

End pliers have jaws at 90% angle

The handles of the nippers must be covered with insulating material. - this is necessary to ensure the electrical safety of the user. In addition, depending on the design of the handles, nippers can be insulated or insulated. The coating of insulated pliers is made of a special dielectric, and the handles of insulating models have cutting inserts as part of their design.

Generally speaking, handles are lever guides. It is their coating that should not wrinkle, slip - it should be resistant to moisture and other liquids, including those that contain a large amount of chemicals.

In addition to these details, the design of the needle-nose pliers includes a special screw lock (it can be single or double), as well as a return spring. The lock is necessary in order to connect the jaws and working parts. And the spring is used to return the handles to their original position or to guide the tool jaws into working condition.

Scope of use

End pliers are used in various fields of human activity:

- in electrical engineering for cutting power cords;

- for working with wires and fittings;

- for cutting aluminum cables of different thickness;

- for working with hardened wire;

- for cleaning wire strands from insulation and other work.

How to choose?

In order to carry out the work most efficiently, it is necessary to purchase a quality product. For this, when choosing, it is important to pay attention to some of the characteristics of the tool.

- Smooth and uniform coating. There should be no scratches, dents or other damage.

- The cutting jaws should fit snugly together, but not overlap.

- If you want to make it easier to work with the tool, and do not want to exert too much effort to bring it into an active position, then pay attention first of all to the nippers with two hinges.

- If you are doing electrical work with needle-nose pliers, pay particular attention to inspecting the handle insulation.

- For professional use, choose the reinforced lever cutters in sizes 120, 160, 180, 200 and 300 mm. Quality tools of this kind are produced by the Zubr and Knipex companies. And also professionals advise you to pay attention to a tool with an absolutely flat cut.

- In addition, when buying, pay attention to the fact that the nippers comply with the Russian GOST (the quality of the needle-nose pliers is regulated by GOST 28037-89). Feel free to ask the seller to show you the certificate and license of authenticity of the product.

An overview of the Knipex nippers is waiting for you in the video below.

The comment was sent successfully.