All about jointers

A jointer is a mechanical hand or electric tool used to level the surface of joinery made of wood. It is present in the arsenal of any master - the processing of not a single solid wood can be done without this tool.

Let us dwell in more detail on the features of the jointer and its popular varieties, as well as give recommendations on the selection and safe operation of equipment.

What is a jointer?

This woodworking tool is needed to change the quality of the surface treatment of the wood blank.

It depends on how well it will work, how tactile and visually pleasing the finished product will be at the exit.

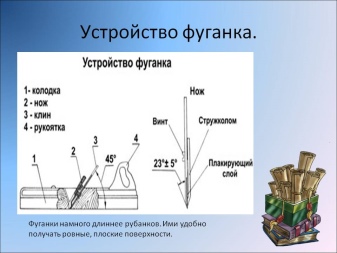

A jointer can have different design features, but in mechanical models it is in any case represented by a combination of the following basic parts:

- pens;

- hulls;

- knife.

Most often, the body is made made of wood, although on sale you can also find metal tools... Models in a wooden version are optimal for working with softer types of wood, the metal is designed for exposure to significant loads with high intensity.

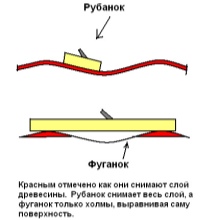

Quite often, novice users have a question about what is the difference between a jointer and a similar plane - both tools allow you to remove layers of wood from the surface.

Despite the functional similarity, there is a difference between them, which is as follows.

- Plane in plumbing it is necessary for the primary processing of the wood surface. Usually, a thin layer of material of a given thickness is removed from the surface of the workpiece. Planing is done to remove bumps and knots. Design features provide for the presence of a knife, as well as a block; in some models, a pair of sharp cutting surfaces is installed.

- Jointer, in fact, is a separate version of the plane, it is considered its more elongated version. Thanks to this structure, the device is pressed against the wooden surface to be treated with maximum force. In this design, two blades are installed - they are the ones that provide finishing. Thus, it is obvious that the jointer, in contrast to the plane, is used for finishing the workpiece.

What is it needed for?

If we dwell more specifically on the functions of the jointer, then it should be noted that such equipment is used in those cases when it is necessary to align large fragments, while initially the workpiece can have significant parameters of length and width.

When planing an initially uneven surface shavings are obtained in the form of small pieces, with repeated treatments it becomes continuous - this indicates that the surface has become perfectly flat.

Classification

In stores there are jointers of different types, the features of which directly depend on the solution of certain tasks assigned to the locksmith.

To size

Depending on the size and configuration, the following jointer options are distinguished.

- Grinder - is a separate type of equipment, which is distinguished by a short body and a slightly increased rake angle.This equipment has a small chip discharge slot. The scope of use of such jointers comes down to removing all kinds of scoring, as well as leveling the end-shaped sections.

- In some cases, plumbing is used half-joiner, it is distinguished by its reduced length. In this case, the width remains at the required level. The semi-finisher is indispensable when processing large-sized wood blanks.

- Falzebel - indispensable for sampling and quartering. Features include a removable sole. Unlike other varieties, this instrument is characterized by a noticeable width and has a rather specialized design.

- Zenzubel - provides a double-sided knife made of high quality steel. The width of this part is 33 mm.

Also on sale mini jointers, they are most often used in everyday life, since they have a rather compact size, but at the same time very high performance.

By material

The materials from which the jointer body is made can vary significantly. Most often found on sale wooden tools, since they have a simple design and at the same time their price is much cheaper. Such options are suitable for a home workshop and, accordingly, for domestic use.

Metal constructions designed for use in particularly harsh industrial environments. Metal is indispensable for high-intensity work, as well as when processing hard wood.

By appointment

The classification of jointers is often carried out according to the purpose of the equipment and how the task is set. In general, tools can be divided into two groups - household and professional.

- Household tools look small and have an affordable cost, they are distinguished by reduced technical and operational parameters.

- Professional jointers larger, they have found their application in the industrial sector. The main advantage of such models is considered to be a long period of operation, continuous operation for a long time and high productivity.

For the processing of wooden blanks that have not been previously processed, the scherhebel is used. In the vast majority of cases, metal is used here, it can withstand even the most intense use.

If after processing it is necessary to fix the finished parts to each other, then preference should be given jointer type tsinubel... This model is distinguished by the presence of notches on the blades - as a result of processing with such a tool, light grooves are formed on the coating.

As the practice of plumbing shows, such a surface is optimal for subsequent gluing, since it provides maximum adhesion of surfaces. If the products obtained at the exit do not need to be glued, then you can do single or double jointer.

By the principle of work

There are two basic types of jointers, depending on the principle of operation: manual and electric.

- Desktop manual jointers can be found in almost all workshops. Their peculiarity lies in the simplicity of design, as well as in a fairly affordable price.

- Nevertheless, in recent years, electric jointers. They are distinguished by simplicity and high efficiency of use. The only drawback of such products is the rather high cost.

Brand rating

Among the most popular manufacturers of jointers are the following brands.

"Anchor Corvette".

The equipment of this company is famous for its versatility, it is designed for low-intensity calibration of sawn timber. Thanks to the well-thought-out layout of the equipment, the tool allows you to perform rough planing, as well as planing at several angles and thicknessing of wood blanks. Jointers of this brand equipped with an additional magnetic starter and a thermal protective coating for the motor... The working potential of the tool is designed for use in a domestic environment.

Interskol RS.

One of the most budgetary and at the same time quite successful developments. It is distinguished not only by high quality, ergonomics, but also by a very impressive working potential. The thermal protection relay of the collector motor is responsible for the duration of work in intensive mode. The security system is also at a fairly high level - the button for activating the tool is hidden under the casing, and the button for turning off the equipment is duplicated by a wide "fungus" that is carried outside the protective cover.

This is a budget model intended solely for home use... The tool can be used irregularly, in low intensity conditions. Enough will be a nice bonus low noise level, and automatic feed, which allows you to achieve an effective result of thicknessing wood of any types

JET JWR.

Represents a group of amateur portable machine tools that grab the attention of consumers good ratio of cutterblock speed, automatic feed speed and collector motor power... The designs of this brand are distinguished by a well-thought-out system for removing chips, the quality of workmanship of folding tables. The protective system of the motor is kept exclusively at a height - it assumes a "claw" mechanism that turns on when the thermal relay unit hits it back, thanks to which the mechanism is able to catch workpieces.

Machines from this manufacturer are in demand by joiners for tasks that require increased accuracy. The only thing that does not allow the equipment to be classified as a professional category is the need for constant cleaning of the jointer sinuses from accumulated shavings.

"Kraton" WMT.

Supplies equipment compact size and fairly low weight - This is a very significant factor for use in home workshops. Such jointers are distinguished by accuracy and reliability, the model is mobile, so it can be used on the road.

The start button is located under the protective cap, next to it there is a button that activates the thermoregulation unit. The planer is stationary under the work table, after switching on the unit begins to move in the vertical plane. Among the advantages are ease of use and high quality wood processing.

Hitachi.

The tools of this brand are distinguished by precise adjustment of the planing depth and increased shaft speed. All this allows us to classify the tool as professional and semi-professional equipment.

The working potential of such jointers makes it possible to process building materials used for the manufacture of doors, windows and other various spatial structures made of wood.

Provided automatic workpiece feeding system. With the correct settings and the selection of a timber or board of suitable dimensions, no problems arise in the work. The only task of the user is to bring the workpiece to the roller receiving it, set up the tool and promptly remove the sharpened element from the desktop.

Selection Tips

When buying a jointer, first of all it is necessary proceed from conditionsin which the tool will be operated, of those purposes and tasks that you set for the equipment. The tool, intended for domestic and industrial use, has a different structure and different technical and operational properties.

It is very important to focus on such parameters as:

- the total number of knives on the working part of the tool;

- power characteristics of the installed motor;

- equipment weight and dimensions;

- the speed of movement of the workpiece to be processed;

- way of removing shavings;

- working potential of the unit;

- body material.

Instructions for use

Jointing is a process of processing wood surfaces of very different densities. Experts give the following recommendations for working with the tool:

- the device is taken by the handle with the left hand, while the pads are held with the right;

- jointer leads near the line of direction of the columns;

- the bottom surface of the wood blank must be precisely leveled, this result can be achieved using preliminary jointing;

- simultaneous processing of several workpieces is allowed only when using a machine that has the necessary technical capabilities.

We draw special attention to the fact that when using the jointer, all safety rules must be observed:

- wear goggles and protective clothing;

- in the process of work, it is strictly forbidden to place your hands at the cutting site, as well as touch the blades;

- before starting work, the jointer must be firmly fixed.

In general, it should be noted that the jointer is considered to be a fairly popular tool. Nowadays, it can be found in almost every carpentry workshop, regardless of whether it is used for domestic or industrial purposes. You can choose the right jointer only on the basis of an understanding of what kind of work you intend to carry out using this tool and in what mode.

For examples of operations performed on a planer machine, see the following video.

The comment was sent successfully.