Trowel (trowel): types and applications

The question of what a trowel (trowel) is, what a tool looks like, often arises among people planning to independently start construction or repair work. Without this device, it is impossible to correctly lay bricks, concrete blocks, and cope with the distribution of plaster. How to make the right choice of a building tool for a bricklayer and a concrete worker, for liquid wallpaper and other materials, it is worth telling in more detail.

What it is?

A trowel is a construction tool that looks like a flat trowel attached to a handle. The colloquial name "trowel" is used in everyday life quite often, replacing the traditional name. A trowel is used to create stone, brick, and other building masonry, using it to distribute bonding solutions along horizontal and vertical surfaces... In household use, it is also used for minor repairs, plastering, working with liquid wallpaper.

The differences between different types of trowels are determined by their purpose. The main structural elements remain in common:

- working part in the form of a flat blade;

- a neck connecting it to the holder;

- lever;

- butt.

Externally, the trowel looks like a scapula with a platform of rectangular, rounded or conical shape. Its parameters are determined by the type of tasks being solved. The working part is made of durable sheet steel with a stainless or galvanized coating. The neck plays not only the role of fastening, but also spreads the platform with the handle in different planes. This trowel differs from a spatula similar in purpose to it.

In addition to determining the bending angle, the neck in the trowel also plays another important role. It determines how the hand will be gripped when working with the tool. The handle, which is attached to the neck, is usually made of materials with a rough surface. It can be wood, plastic, rubber, or a combination of different materials.

Heavy steel and lead handles are rare, but they have a significant advantage - impact resistance.

The butt in the design of the trowel also plays a rather serious role. It is made of durable materials and is located at the end of the handle. This element is tapped on the masonry stone to ensure it is correctly positioned. The butt must be firmly in place, its displacement during operation may cause the handle to split..

The scope of the trowel is quite narrow. The trowel is considered a specialized tool for masonry work. with concrete mortars, other building mixtures. Even with a flat and smooth platform, it is convenient to distribute tile adhesives and plasters. By blows from the working part of the tool, you can create original chips on the surface of stone and ceramic tiles. And a trowel is sometimes used as a scraper.

Varieties of the instrument

As a professional masonry tool, the trowel has a corresponding GOST standard that determines its main parameters. This document contains the dimensions, characteristics, purpose of the trowels. It is very important to consider all these factors when choosing the right tool for specific types of work.

For a concrete worker

The metal trowel, which the master works with in this case, slightly resembles a bucket due to the rounded front part. Myself the tool has a triangular working platform 120-180 mm long... The main purpose of concrete trowels is leveling the mortar in the screed, stirring the prepared composition.

Do not confuse them with a tool for foam blocks: glue is applied to them with other types of trowels.

Working with concrete mortar with a trowel is often associated with the use of mechanized tools. When using special mixers, it is with this tool that you can easily and quickly clean off excess mixture from the walls. Distinctive features of this type of trowel can be called massiveness, as well as the smooth stainless surface of the working platform.

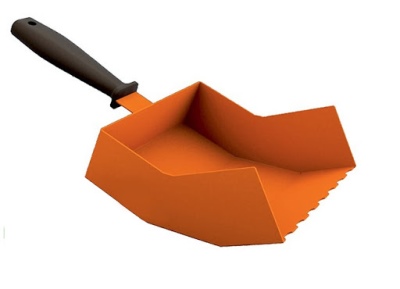

For aerated concrete, a special bucket trowel with a notched edge is most often used.resembling an excavator bucket. Its blade width varies in the range of 100-400 mm. The main difference between the tool is its versatility. Such a trowel can simultaneously capture the mixture, participate in its application and form a relief.

For a bricklayer

The trowels used for masonry are the classic version of the tool.

The trowel of a bricklayer, stove-maker has the following characteristic features:

- triangular shape (closer to the trapezoid);

- rounded corners;

- dimensions 120-180 mm;

- indirect neck bend angle.

Such trowels are used for laying various mortars on a mineral or cement basis.

In construction, they are used for the installation of gas blocks, bricks, foam concrete, natural and artificial stone. It is believed that the tool for a bricklayer and a concrete worker is completely interchangeable, but practice shows that there are still differences.... It is much more convenient to work with specialized devices, moreover, the difference in the position of the handle can give an experienced craftsman some discomfort.

For the tiler

The tile trowel is available in a wide range of sizes and the working platform can be up to 17.4 cm in length. They all differ in a teardrop shape with a rounded nose. For jointing and other types of work that do not require a large amount of adhesive, special models are used. A small trowel for filling joints is much better than a spatula, it is quite possible to choose a universal tool that is convenient for use when laying with different sizes of gaps.

The classic purpose of a trowel when performing tiling work is also quite obvious. With its help, the prepared solution or adhesive is thrown onto the tile. Typically, these tools have a slightly rough paint finish to ensure good adhesion. The solution thrown with a trowel is spread over the tile with a comb.

For finishing works

A trapezoid trowel with sharp corners is also used. He is indispensable in the work of a finisher. With the help of this tool, plaster compositions are scooped up and scribbled... Work with them is carried out with a trowel with a smooth surface, which allows the mixture to easily come off the scapula. This type of product is not used for smoothing and smoothing.

For plastering

A trowel with a wide drop-shaped base and a pointed tip is also included in the group of finishing tools, not masonry ones. Its shape is selected taking into account the peculiarities of the work performed. Plastering trowel is used for leveling mixtures on the surface of the walls... This option is well suited for classic compositions, Venetian coatings, but special spatulas are much more suitable for the bark beetle.

In general, trowels are rarely used today in plastering work. They were replaced by various options of spatulas, allowing not only to level the surface, but also to give it a certain decorative effect.Trowels are used less often, but provide wider surface coverage, which can be important when working with quick-setting mixtures.

For the initial stage of plastering work, a trowel resembling a bath ladle is used. - with a bottom and tapered walls. It sprays a liquid solution onto the surface. This tool has practically no neck - the handle is fixed directly on the base.

Trowel

If the notched surface of the trowel is considered optimal when working with decorative plasters, then where it is required to bring perfect smoothness, it is the trowel that remains indispensable... The trowel has noticeable differences from the classic trowel. Its work platform is square or rectangular, and the neck and handle are not located at the back, but in the center. This combination allows you to make the "smoothing trowel" convenient for finishing the surface.

Trowels are used for finishing ceiling and wall surfaces... They are convenient for applying Venetian plaster and other compounds that require the perfect smoothness of the finished coating. When ironing, it is also impossible to do without using a trowel. Surface treatment with such a tool allows you to compact the decorative coating, make it glossy.

Trowel with a comb

In contrast to the classic "trowel", the trowel with a comb has serrated projections on both edges. The length of their sides varies, it can reach 8 mm. These square teeth are designed to work with adhesives, which must be applied not in a continuous layer, but in stripes.... Trowels with a comb are considered a special tool for tilers. They easily replace spatulas and are also suitable for ironing surfaces.

Jointing trowel

The narrow and long jointing trowel also has its own specialization. It is used when filling joints in masonry between building blocks, natural stone... The width of a flat platform with a rounded end is determined by the type of material to be worked with. Trowels are an alternative to a putty knife, they allow you to accurately and quickly fill the voids and gaps in the masonry seams. They are also called rusticated ones.

For internal and external corners

Trowels used in plastering work can have a narrow specialization. Their angular variety is used in cases where it is necessary to ensure correct and accurate finishing in places with difficult access.... The special shape of the "book" with an angle of 90 degrees allows you to apply the solution, evenly distributing it.

Corner trowels are divided into external and internal.

For liquid wallpaper

When working with modern finishing compositions, the tools have to be selected appropriate. The trowel for liquid wallpaper is designed taking into account the characteristics of this material.

It allows you to:

- adjust the coating without damaging it;

- see the result (transparent trowel);

- reduce the pressure exerted on the surface.

Tools of this type can be made from polymeric materials rather than metal.

Most often, acrylic trowels are taken, solid or combined. You can take the appropriate spatulas in the kit. It is better to take metal trowels from stainless steel, ironing and corner... Acrylic models often have a plastic ergonomic handle for a more comfortable working experience.

Transparent trowels for liquid wallpaper have proven themselves especially well when working with decorative coatings. They not only allow you to see the result of labor, but also make it possible to control the thickness of the layer, immediately detect defects.

Plastic trowels are safer, do not damage the setting coating. They do not stick to the composition, like metal counterparts, they glide well.

For slopes, corners, areas around outlets, a trapezoidal trowel is useful... When processing niches, arches, rounded elements, a trowel in the form of an iron will be absolutely indispensable. When preparing everything you need to apply liquid wallpaper to the walls, you should make sure that the right tool is at hand.

How to choose?

The main criteria for choosing the right trowel are not only in its functionality or purpose. Much more attention should be paid to the materials from which the working part of the trowel is made.

- Stainless steel... This is the most durable type of base, resistant to corrosion, shock loads, mechanical damage. From a polished shiny surface, the solutions come off as easily as possible. Tools made of this material can be easily cleaned, but when working, they require more care and accuracy.

- Black steel... As in the case of stainless steel, this material is cut by stamping into pieces of the desired size. To protect against corrosion, the surface is painted or covered with a galvanized layer. The mortar adheres to the surface of an ordinary steel trowel quite well, which leaves more room for maneuvers when throwing, aiming. Black metal tools are more difficult to clean, but much more suitable for those new to masonry.

It is worth paying attention to the design features of the handle. The best solution is considered to be a combined version of plastic with a rubberized coating. It strikes a balance between lightness and ease of use.

Composite handles are well balanced and comfortable to hold in the palm of your hand.

How to use it correctly?

Working with a trowel when laying stone, grouting joints or smoothing the surface always has its own characteristics. To master the subtleties of the art of owning a trowel will be useful to absolutely everyone. Moreover, even a home craftsman periodically has to carry out repair or plastering work.

Here are the basic rules when working with a trowel.

-

Technique... When working with cement mortars, throwing the mixture onto the masonry surface is carried out exclusively with a hand. You don't need to use your elbow or shoulder, or the fatigue will come too quickly. It is worth considering that each set of material adds weight to the trowel's own mass of 400-600 g.

The hand should not be allowed to feel the load too quickly, otherwise it is unlikely that it will be possible to complete the work quickly.

- Acceleration... This point is very important when working with plaster compounds. At the moment of throwing, it is necessary to collect the mixture on a trowel, and then perform a sharp movement from oneself with a stop. In this case, the solution will easily come off the working platform of the trowel, being on the surface to be trimmed due to the force of inertia.

- Individual adaptation... The bend of the tool neck determines the comfort in working with a trowel when performing a certain range of tasks. But it must also correspond to the anatomical features of a particular person. If discomfort is felt when pouring or distributing the solution in the hand, it is worth experimenting with the angle of the neck. A correctly set trowel will provide maximum speed and ease of use.

- Working with liquid wallpaper... This type of composition is radically different from classic plaster. The same trowel can be used for both sketching and smoothing. In this case, the mixture is applied to the surface of the tool, then it is applied to the wall, rubbing the material in a circular motion.

It is not necessary to observe a single direction of movement of the trowel - it may well move haphazardly.

- Application when laying... On a building stone, brick, the mortar is applied with a trowel from the butt edge. There is also a technique in which a layer of the assembly mixture is applied to the base in excess, so that when laying, part of it is on the side. Excess cement must be removed immediately with the same trowel. At the end of the masonry, a narrow trowel is taken, jointing is performed.

Considering all these recommendations, it is possible to provide convenience when using a trowel in carrying out construction and repair work.

This tool is still in demand and relevant. The ability to own it will allow you to do without outside help when performing simple types of masonry, gluing tiles or plastering walls.

The comment was sent successfully.