Cable cutter: features, types and their characteristics

When carrying out electrical work, a tool such as a cable cutter is often used - this is a compact device that helps to neatly cut electrical cables. Before buying a cable cutter, it is necessary to take into account the characteristics and types of the device as a whole, the features of the products of various companies, as well as the rules for working with it.

Main functions

Such a tool is very popular for the installation and dismantling of cables. This device looks like pliers, only it is equipped with special sharp jaws on the inside, with which the cable is usually cut. And also this tool may have additional compartments for stripping insulation from conductors. However, not all cable cutter models are equipped with this feature. There are models of devices that are used for laying high-voltage power lines.

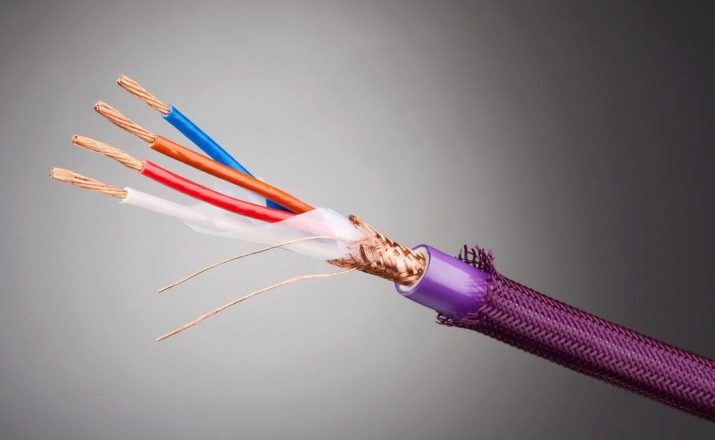

Such a tool is designed to work with a very wide range of wires. Cable cutter models are available that can cut the following wires:

- reinforced cable with a large cross section;

- reinforced fibers;

- copper cables;

- aluminum cables;

- optical fiber;

- twisted type cables;

- armored;

- coaxial.

Important! It must be remembered that there is no universal tool that can work with all types of materials at once. Each of them needs a different type of device. If you use your cable cutter for other purposes, it is likely to deteriorate quickly.

Varieties

On the market for devices for electrical work, there are various types of cable cutters, which differ in ease of use and price segment. Each type of device has its own unique set of characteristics. It is worth considering in more detail the popular types.

- Deserves special attention device capable of handling live wires... It differs in that it is equipped with reliable insulation, which minimizes the risk of contact between the hands of the master and the surface of the cable. Professional models of this type are usually used only with a special dielectric material in the hands of the installer, for example, rubber gloves.

- The most widespread are mechanical or manual types of tools. They are small in size, as a result, and light in weight, and are used mainly for domestic purposes. Such cable cutters can be used to cut wires with a diameter not exceeding 2 cm. The exact range of the device is usually represented on its handle in the form of the inscription "D = ... mm", where in place ... a specific number of millimeters is indicated.

The materials that hand-held cable cutters can handle are limited to copper and aluminum. It is not recommended to cut cables containing a wire rope or steel screen. Such wires can deform the tool blade. On the handle of the cable cutter it is usually written what materials it is intended for.

The mechanical electric devices themselves are divided into several types.

- Electrical scissors have a design similar to the stationery counterpart. But their blades are shorter and tighter. A similar tool is usually used in the repair of electronics, as well as household appliances, which often include small thin wires.

- Lever type pliers most similar in appearance to pliers and equipped with small inwardly rounded blades. This design allows a large touching area to be covered when cutting the cable. And also on the inner sides of the handle there may be special notches designed for stripping wires.

- The most powerful hand-held cable cutter is sector option, in the design of which there is a ratchet mechanism. It allows you to cover a fairly thick cable. The lever arm in such models is usually increased due to the fact that it consists of long tubes. This design feature reduces the load on the hand of the master during work.

- Hydraulic cable cutter is a much more massive device, weighing 7 kilograms. It is used to work with power lines in the air or underground. The tool is capable of cutting very thick wires because the metal for the blades in its construction exceeds the density of the materials that make up such wires. It is called a hydraulic cable cutter because it consists of a hydraulic cylinder that will pull the stem when the handle is wiggled. This provokes the occurrence of strong compression, as a result of which the wire is cut. The handle itself is a hydraulic cylinder, the rod of which moves the blades with a push, while the hydraulic fluid is pumped using a thin lever. It is impractical to use this type of cable cutter for cutting thin wires. The process becomes inconvenient due to the fact that the device is not compact. And this design also works rather slowly with the expectation of cutting a cable with a large diameter, for example, 160 mm and even 250 mm.

- Electro-hydraulic models differ from the previous ones in the way of pressure on the hydraulic cylinder. The analogue of a lever in such tools is an electric motor, and hydraulic fluid is pumped in just after pressing one button. Such devices for cutting electrical wires are divided, in turn, into battery and network devices. Rechargeable batteries have a removable battery that allows you to work where there is no power supply. Network devices, on the other hand, work only when plugged into an outlet, therefore, cannot be used outdoors. The weight of such structures is the largest. But their distinctive advantage is the fastest speed of work.

Popular models

Before choosing a cable cutter yourself, it is recommended that you familiarize yourself with the characteristics of the products of the most demanded companies on the electrical equipment market.

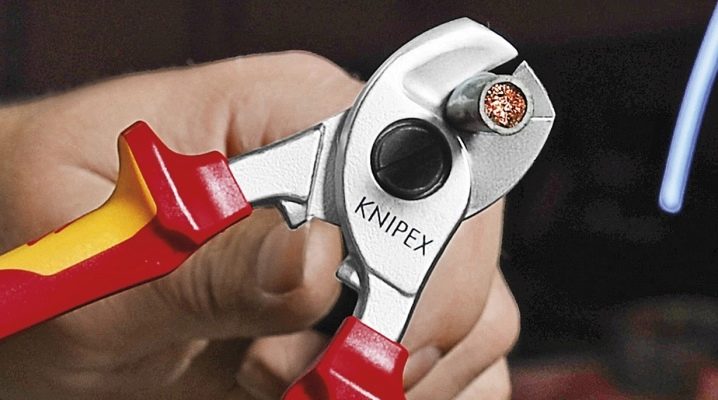

- Knipex Cable Cutters characterized by a long service life. They are often equipped with parts for stripping single core cables. Some models, such as Knipex KN-9511200, are capable of cutting both thinner and tighter wires.

- Tools of the firm "Zubr" are made of durable materials. They are easy to use and can cut wires neatly. Buyers highlight the Master 23343-15 model, which is of high quality at a very affordable price. However, it is not suitable for handling armored cable.

- German quality presented in cable cutters by Gross... For example, the Gross 17725 can operate at voltages up to 1000 V. An added benefit is its anti-slip design. The handles of the tool are very comfortable and the blade is coated with a special anti-corrosion layer that will ensure a long service life of the cable cutter.

- Rigid Firm specializes in the production of ratchet-type cable cutters. Such a mechanism makes the process of cutting wires easier, thereby providing not only productive, but also comfortable work.

How to use?

Cable work can be carried out by both professional electricians and amateurs, depending on the scale of the work. Non-professionals can only cut a cable that is not energized in a domestic environment. To do this, you need to perform the following sequence of actions:

- make sure that the electricity in the apartment is turned off;

- if you are dealing with an electrical appliance or household appliances, make sure that it is not turned on;

- carefully calculate the location of the cable cut, since an error can completely break the equipment or require redoing the entire system;

- Place the cable in the space between the blades and cut it at the intended location using the movement of the cable cutter handles.

As you browse through the lists of the best cable cutting tools and the specifics of the job ahead, you will be able to find the best quality hand, hydraulic or electric powered tool.

For more on cable cutters, see the video below.

The comment was sent successfully.