Electric nail guns: features and types

The nailing tool allows you to perform monotonous work faster and without much physical effort. Modern units represent a wide variety of species. To find the right one, you need to take into account all the nuances and features of this tool.

Peculiarities

The electric nailer has several names, such as nail nailer, nailer, nailer, nailer, or simply nailer. The design of the device consists of a body, a handle with a trigger, a special device called a magazine for nails, and a piston that provides a pressure of 4-6 atmospheres. This is enough for the nails to firmly enter any surface.

The piston device is activated by pulling the trigger. Simultaneously with this action, compressed air is pushed out of the handle. Nails with some acceleration are firmly in the base. Fasteners are unable to pass through walls. The nails themselves do not have kinetic energy, therefore, at the moment of stopping the action of the pistol, they also stop their course.

The devices are actively used in construction and finishing works, and they are also used by furniture assemblers.

The only inconvenience in using a nailer is the need to purchase special nails. Conventional fasteners do not fit it.

The use of assembly guns significantly reduces the time to complete the work, saves physical labor costs. When it comes to large-scale work, it also significantly reduces the cost of fasteners. In addition to professionals, the gun is actively used by home craftsmen. The features of compressed air driven nail guns differ in the use of nails or staples.

Staple versions of pistols are distinguished by a simpler device. Some models are equipped with special studs. They prevent the tool from slipping out of the hand. Other products are equipped with re-shot protection mechanisms.

Among the advantages of electric models are the following:

- light weight;

- normalized recoil force;

- ease of use.

There are also disadvantages:

- energy dependence, which is why the tool cannot be used in buildings under construction with electricity that has not yet been supplied;

- low resistance to moisture;

- weak power and low speed of operations;

- limitation in the permissible size of nails - 65 mm.

Network options are convenient for finishing work. It is convenient to fix panels and other light sheet materials with small hardware, pins or pins. When working, it is recommended to take into account the mandatory presence of a socket for connecting the tool. An ordinary household 220 volt network can act as a power source.

What are they?

The types of electric hammers are divided into mains and battery. The small battery-powered nailer is better suited for hammering in topcoats. The tool is usually equipped with an impact force adjustment. High precision is essential in nailing finishing material. After all, from the excessive power of the striker strike, ugly dents remain in the cash.

Such units are more expensive due to the cost of a good battery. Powerful battery models are not cheap, and you need two.One for the duration of the work, and the other for the reserve, when the working copy runs out of charge.

The cordless nailer is more convenient to use on trestles, stepladders, under the ceiling. The construction battery version is more used as a roofing tool that is not suitable for working on concrete. On the plus side, up to 700 nails can be driven in on a single battery charge.

Low weight and small dimensions of electrical network options are one of the advantages of these tools. The drum magazine of the devices allows you to charge up to 300 nails. This number of nails adds significant weight to the apparatus. Cassette versions of products are considered the most convenient to use. The cassette does not increase the size of the tool, but allows you to get to hard-to-reach places: it is convenient for the lining, which is nailed to the ceiling.

One cassette holds about 150 fasteners. Electric nailers are characterized by a rate of fire of the order of one shot per second. It does not count as fast, but it is effective for finishing that requires precision.

For ease of use, net nailers are supplied with long electric wires (about 5 meters). This allows for continuous work that can only be stopped for lunch or when consumables in the cassette run out. Low-power devices heat up during long-term operation. The impact control of the mains tool has a very wide range.

Neilers are subdivided according to their area of application.

- Roofing electric guns. They are equipped with drum cartridge belts. As fastening elements, brushed nails with an enlarged head are used. The permissible length of nails is 25–50 mm. The tool is used to fix soft sheet roofing materials.

- Finishing guns needed for fastening moldings, platbands, skirting boards and glazing beads. Acceptable fasteners are thin, capless studs that fit in cassettes. The tool is equipped with a depth adjustment and a rubberized tip that does not scratch the surface.

- Frame nailers are similar in principle to the previous version, but allow the use of nails up to 220 mm. The tool is used when erecting structures made of wood, for example, rafters.

- Cover nailers allow the use of fasteners with a length of 25–75 mm with a standard head. The tool is used in finishing works using plywood, chipboard and other sheet materials.

- If the sheet material is supposed to be installed on the crate, special devices for drywall are needed. The tool fits rough nails with a length of about 30–50 mm. It allows you to screw in and drive in fasteners at the same time. Products are sometimes mistakenly called screwdrivers.

- If a washer is used as a fastener, you need to choose naylers for installing insulation.

- Another version of an electric gun is called a parquet. The main feature is the L-shaped hairpin. The clogging is adjusted at an angle to the surface with special rollers. The tool is supplied complete with attachments and other necessary accessories in a special case.

Rating of the best models

The pros and cons of popular assembly gun models are judged by customer reviews. For everyday life, devices are selected that are undemanding to maintenance, maintainable and versatile.

These include the nailer "Zubr"... Small hardware is suitable for the tool. It is actively used by furniture makers. The product is networked, provided with a 2.5 meter cord, mobile. There is protection from accidental use in the form of a special key, there is a regulator of the impact force. For the device to work, a 220 volt home network is sufficient. In addition to hardware, pins and staples can be loaded into cassettes.

Tools "Bison" not suitable for finishing, as it leaves traces around clogged fasteners. The disadvantage of the product is the possible jamming of the striker and fasteners. To fix the problem, you will have to turn off the device and disassemble the cassette.

DeWalt product - cordless version of the nailer with a rack magazine. The DCN 692P2 series stands out for its weight of 4 kg and excellent balance. The convenient depth adjuster is optimally positioned above the barrel. The recoil is small, even with 50–90 mm nails. The tool can work at an angle of up to 350 degrees.

There are indicators of jamming and overheating. Stuck hardware can be easily removed. Cassettes are designed for 55 hardware. Of the shortcomings, the coil backlash that appears over time is noted, which users attribute to the frequent use of the tool. Average service life - 70 thousand shots.

Hilti BX 3 ME - mounting option on a battery, which is characterized by increased power. The tool can be used to fasten metal parts to concrete and brick. The built-in battery is rated for 700 shots. The barrel of the device is designed in such a way that it allows working at right angles to the structure. The support piece can be removed if necessary.

The model is quite expensive in price. Another disadvantage is the lack of a regulator. Fasteners for the tool are advised to take only branded ones. Cheap counterparts break easily.

Not suitable for work on concrete with small hardware. The positive characteristics of the tool include non-slip handles, protection against accidental shots, and the visibility of a battery charge. Among the disadvantages is the small capacity of the cassette - 40 fasteners.

Nailer Bosch GSK 18 V-Li has a high operating speed and a volumetric cassette for 110 fasteners. The device is universal, suitable for various areas. The kit contains two batteries at once. The tool is equipped with a convenient carrying and regulator. Fasteners can be easily inserted into cassettes. The material of the handle is non-slip.

How to choose?

The choice of a nailer should be based on the following parameters:

- classification;

- area of operation.

The main varieties of the instrument are subdivided into drum and cassette. In the first version, the fasteners are fastened together with a wire. The result should be a roll.

In cassette versions, the nails are connected to each other by a straight line. This usually happens with a special plastic device. It takes the form of a rail or clip. The weight of the first variety is greater due to the fact that more nails are placed in it. At the same time, this condition makes it possible for a larger number of operations without additional recharges.

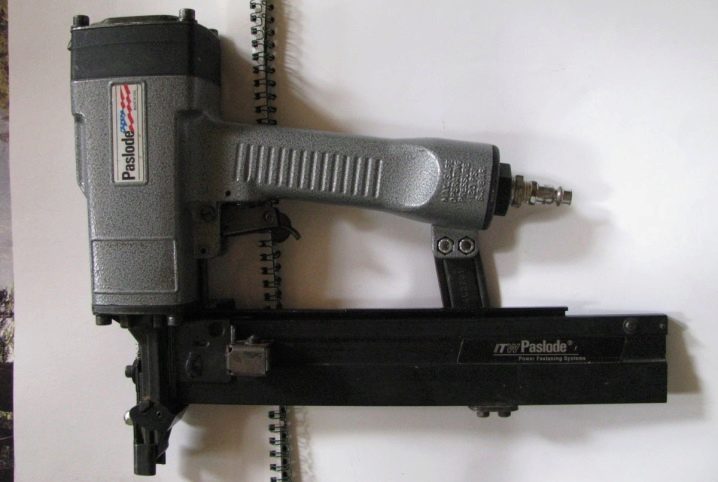

The classification by field of application, presented in the article above, is conditional. Individual models are difficult to unambiguously relate to any category. Tool types are often divided into groups based on the type of drive system. She, in addition to electrical, is also of the following types:

- mechanical;

- pneumatic;

- gunpowder;

- gas;

- combined.

Special technological solutions are hidden in the combined nailers.

This gun is equipped with a pneumatic cylinder containing compressed nitrogen. It makes the piston system move. Its return to its place is provided by an electric motor connected to the accumulator block. The cycle is considered a closed type, but the battery requires periodic recharging after about 500 shots. Positive aspects of the combined modification:

- good rate of fire in comparison with conventional electrical units;

- no exhaust when compared with gunpowder or gas cannons;

- autonomy and greater convenience in comparison with network options.

The device has disadvantages, but they are insignificant:

- the need to monitor the level of recharge;

- high cost.

The division according to the area of destination is associated with the restriction on the possible use of certain fasteners. Manufacturers themselves often subdivide their products on this basis. However, in practice, many models are equipped with adaptive nozzles. They allow different types of fasteners to be used in the same drum or cassette.

Usage Tips

The main advice for all nailer buyers is to carefully study the operating information. Precautions are needed for greater safety in the work and maintenance of this type of tool. Failure to follow the safety precautions can result in serious injury. To avoid any trouble, the operator should be aware of the following.

- When working with the pistol, it is recommended to wear protective goggles with side shields, which will provide protection from flying objects.

- The power supply for any assembly gun must only be certified. The use of substandard elements may result in an explosion.

- It should be understood that the tool contains fasteners that could damage the operator or others. The instrument should never be turned on for entertainment purposes.

- If the nailer is powerful, it can be a good idea to use headphones to protect your ears from excessive noise.

- It is important to store the tool in a place that will be inaccessible to children and unauthorized persons. Access to the instrument must be limited and the storage area must be dry and clean.

- It is advisable to remove flammable liquids and gases from the place of work with the gun, since the included tool produces sparks.

- It is important to check the fastening of the parts before using the tool. It is important to periodically check the number of fasteners loaded into the cassette.

- When loading fasteners, do not press on the "Start" button.

- The working position of the tool is often downward. Deviation from the corner of the work surface can lead to bruises

Special care must be taken when returning the spring mechanism to its place. Continuous operation entails a firm and quick pull on the trigger. During work, do not lean too close to the surface. If the instrument makes strange noises, turn it off immediately.

.

For more on electric nail guns, see the video below.

The comment was sent successfully.