Manual pipe benders: what are they and how do they work?

During repair work, it is often necessary to change the shape of the pipes. You can achieve the desired result using a special tool - a manual pipe bender. In our article we will tell you more about the device of this tool, its varieties and give an overview of the most reliable models.

What it is?

A pipe bender is a tool designed for bending pipes made of a wide variety of metals. The use of the equipment makes it possible to ensure the most uniform deformation at the required angle. Bending occurs smoothly, the appearance of breakages, unaesthetic folds is excluded - this is extremely important if the pipes serve to transfer liquid and gaseous substances, in which case their throughput will remain at the same level.

With a hand tube bender, you can deform metals such as stainless steel, copper, titanium, aluminum or brass... Compression and change of shape occurs under the influence of the physical force of a person - an operator. This machine is not tied to one place, it is mobile and can be easily carried from one place to another. In order to reduce the stress on the operator's hands, the mechanism is equipped with extended levers.

The main disadvantage of such a tool is that it cannot be used to carry out work on a large scale. Deformation of pipes requires large physical costs, therefore, after several deformations in a row, the operator is very tired - one person cannot work for a long time. However, if repair work is carried out by a team of workers, then they can replace each other, and this defect will not be so significant.

Manual pipe benders are inexpensive, they are lightweight and maneuverable, so they are often used in work by gasmen, plumbers and other craftsmen involved in heating systems.

With the help of a hand-held machine, if necessary, bending can be carried out directly at the installation site, without spending time and effort on moving large-sized pipes to the production workshop.

With the help of a manual pipe bender, you can also bend the elements of frame structures:

- sports equipment;

- supports for garden vines;

- furniture;

- greenhouses and greenhouses;

- porch canopies.

The use of a pipe bender allows the production of single-sided workpieces, these works are in demand when erecting frame structures, for example, greenhouses and greenhouses.

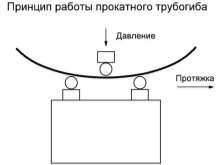

Device and principle of operation

The mechanism of operation of the pipe bending machine is based on the possibility of deformation of the tubes along a certain radius. For so that folds do not appear inside when the metal is bent, it is necessary that the size of the bend zone corresponds to approximately 3-4 diameters of the workpiece... If the machining is shorter, the desired geometry will be broken.As a result of such an impact, a material with thin walls folds into a corrugation or simply breaks.

When using a manual pipe bender to work with welded tubes, there is always a risk of seam divergence - high quality bent products can only be achieved when working with seamless workpieces made of soft material.

The principle of operation of the tool is simple: the pipe is clamped inside the machine, the arms are folded, thus producing mechanical pressure on the walls of the workpiece. The contact points are in the form of rollers, so the tool rolls without problems around the entire perimeter of the pipe, ensuring uniform pressure along the entire length. Such processing allows you to completely eliminate the appearance of dents in places of pressure.

The edges of the workpieces are blocked by roller stops during operation, so the pipe does not move away - this ensures maximum work safety.

Species overview

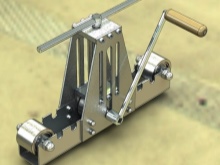

Lever

It is a handy tool that can be used on copper as well as metal-reinforced plastic and thin-walled pipes. The principle of operation of such a device is quite simple: each mechanism has a roller suspension, as well as a half-roller and a pair of levers. The workpiece is formed under the influence of the physical force of the operator and is fixed with a clamp. This processing allows pipes to be bent at 180 degrees.

The undoubted advantages of a lever tool include:

- the ability to bend metal in weight without a fulcrum;

- a large number of pipes with an equal bend angle can be processed with a roller;

- the presence of a lever multiplies the pressure on the metal and at the same time reduces the required application force of the operator.

Spring loaded

From a technical point of view, this hand-held pipe bender is the simplest tool - an ordinary elastic spring, which is able to perfectly hold its shape. There are no complex elements in this design, the impact is carried out with the help of muscle strength. Available in two versions - external and internal... In the first case, the spring is applied to the pipe, in the second it is inserted into it. Optimal for working with rolled copper, as well as plumbing fixtures made of metal-plastic.

The use of a spring tool allows you to create the desired angle, while minimizing the risk of metal damage... The advantages of such a unit also include the ability to bend pipes "by weight", as well as giving the desired shape to the pipe already connected to the water supply system. However, there were some drawbacks: there is no roller under the workpiece, so the fold can be of arbitrary shape. In addition, each spring can be used exclusively for pipes of a certain diameter.

The scope of the equipment is limited to thin-walled plumbing pipes.

Auto

Such a device is an automatic version of a manual pipe bending tool, from its "prototype" it inherited the angle mechanism of work, the ability to work "on weight" and bending along a moving roller. Such a pipe bender can be moved from place to place, and its dimensions, as a rule, do not exceed the dimensions of a standard perforator.

Suitable for deformation of the following types of rolled products:

- copper thin-walled pipes with a diameter of less than 1 inch;

- steel thin-walled pipe with a diameter of up to 25 mm.

The better the gearbox is, the longer the tool will serve.

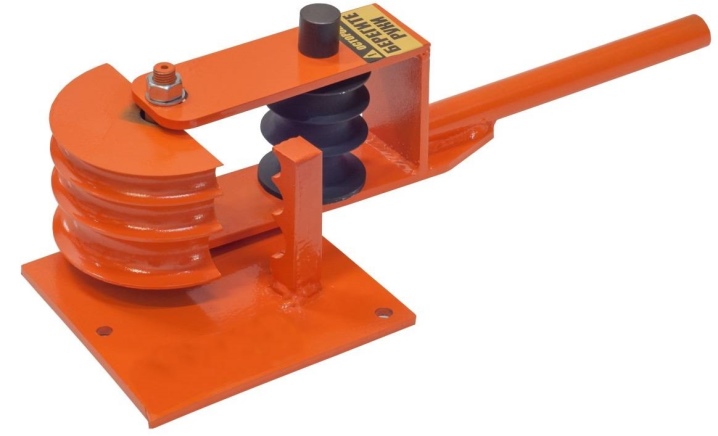

Crossbow type

This is a universal device, the functioning of which is carried out thanks to replaceable nozzles for tubes of a certain diameter. It looks like a T-shaped structure, on one side of which a pipe holder is attached. A lever that transmits physical strength is located perpendicularly. Muscle strength is most often used in the operation of the equipment, but there are models where the force goes to the bending shoe.

The crossbow pipe bender provides bending of rolled pipes in the range of 0-90 degrees, the device works with both soft and fairly hard metals, allows bending copper, brass, steel, metal-plastic. This type of pipe bender has its own drawback, and a rather significant one. Each type of rolled metal requires its own nozzle, if chosen incorrectly, this can lead to a change in the internal size of the pipe or even rupture of the workpiece.

Before starting work with thin-walled workpieces, it is advisable to fill them with sand. This will allow the pressure to be redistributed correctly.

Top Models

Today, there are hand-held pipe benders of various manufacturers on sale - Ridgid, Rems Sinus, Zubr, Stalex, Blacksmith. According to user reviews, such models have the highest performance characteristics.

Stalex TR-10 100308

This manual pipe bender is ideal for use in a personal workshop or small business. The cost of the instrument is low - about 5,000 rubles, the features of the mechanism allow you to work with tubes of various diameters without changing the equipment. The design provides for three types of frames, as well as a high stop for fixing the part. The platform has three holes to allow the equipment to be mounted on a horizontal support. The mechanism is made of tool steel, powder painted, this creates an effective protection of the material against corrosion.

The advantages of the model include:

- affordable cost;

- reinforced frame with a thickness of 6 mm;

- suitable for tubes of 20, 25 and 32 mm;

- working range of bending 0-180 degrees;

- compact size, thanks to which the module fits easily into the trunk;

- weight is only 15 kg, which creates additional convenience when working on the road.

Among the disadvantages are:

- a shortened handle, therefore, most often it is additionally lengthened to make the bend more convenient;

- poor quality of welds, which dictates the need to digest them again;

- the central hole has a matrix shape, therefore, when working with 32 mm pipes, certain difficulties arise, you have to think about where to move the attachment point.

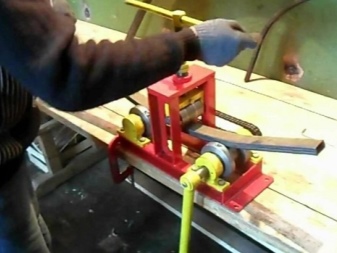

Smart & Solid BendMax-200

The optimal manual tube bending machine for working with square and rectangular profiles. It is made of dense steel, due to which there are significant loads during bending. A pair of rollers located in the lower part of the structure acts as stops, the third is supplemented with a crank handle for efficient rolling of parts. Deformation is carried out by stepwise pressing of the screw; a scale with divisions in degrees is provided on the face plate.

Pros of the model:

- body made of extra strong thick steel;

- physiological braided handle for easy grip and slip prevention;

- compact size;

- allows you to work with pipes with a diameter of 15 to 40 mm and a wall thickness of up to 2 mm.

Minuses:

- high price of equipment - from 13,000 rubles;

- lack of limiters at the edges and at the end;

- weight is about 23 kg.

How to use?

It is very important to follow the safety rules when working with the manual tube bender, as the device poses a certain risk of injury. In order to avoid damage, it is important to observe the following requirements. It is forbidden to approach the pipe from the edge from which the bend is formed.... When the guide slides off, the metal workpiece begins to spring in the opposite direction, and the pipe can hit the stomach or chest, and the impact will be quite high. This can lead to broken ribs and damage to internal organs. Ignoring this rule is fraught with the most dangerous consequences. There is also a great risk that the shaft where the roller is fixed will simply fly off under the influence of strong pressure.

If the workpiece is physically influenced in order to deform, do not hold it with your hands, you can touch the pipe only after the efforts are stopped... If the pipe bending machine is capable of operating at different speeds, then it is not recommended to set the maximum one. A high deformation rate often causes breakage of the workpiece, as a result, the pipe falls and presses the operator's legs, and if the pipe is rather long, it also grabs the limbs of people standing next to it.

You can find out how to make a manual pipe bender yourself below.

The comment was sent successfully.