Choosing a pneumatic spray gun

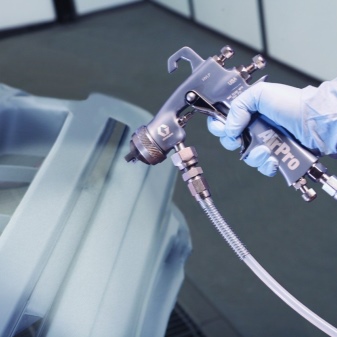

Rollers and brushes are not the only painting tools, although it is too early to talk about their obsolescence. And yet, there are such volumes and types of work in which the process would like, if not to automate completely, then at least to bring it closer to it. A pneumatic spray gun will perfectly cope with this mission.

Device and principle of operation

The main purpose of this device is to spray various kinds of paints and varnishes with compressed air. This is not exactly paint, although the name of the device means it, it can be primers, antiseptics, even liquid rubber and other agents that can spread over the surface in such an air way. Pneumatic models are combined with compressors that pump air into the paint sprayer through a hose. Under pressure, it works as a paint breaker, and it breaks up into small particles and is pushed out of the nozzle of the device.

The air flow rate in the compressors can be different - from 100 to 250 liters per minute. It all depends on the power of the device. Apparatus for high and low pressure are on sale. Household appliances are usually compact, with a power of about 2 kW, piston with an electric drive.

To store compressed air, they have receivers with a capacity of up to 100 liters.

And you can control the flow of the dye mixture using a hand gun. It looks like a simple household spray bottle, but the container does not contain water, but paint. In order to more accurately regulate the flow of paint, there is a special needle in the nozzle of the gun. The instrument has adjusting screws to control airflow, amount of paint (or other supplied substance), and the width of the paint torch.

The tank in which the coloring or other sprayed substance is stored is fixed to the gun from either side: from the side, from below, from above. It depends on the design features of the device. If it is a homemade spray device, a plastic bottle with an adapter can become the paint tank.

You can work with the spray gun in the temperature range from +5 to +35 degrees, the relative humidity should not exceed 80%. The materials used for the spray gun must have an ignition temperature of at least 210 degrees. The person working with the spray gun must take care of his own safety.

It is supposed to work in a respirator, goggles and gloves so that the chemical liquid does not get on the body tissues. The space for painting must have supply and exhaust ventilation.

The very surface to be painted must be made clean, dry and fat-free, it is also additionally treated with sandpaper, and then dedusted.

Advantages and disadvantages

The pneumatic spray gun has a major competitor - an electric device. It operates on an airless spray system, expelling a stream of material under pressure. Such spray guns are indeed very effective and quite rightly in demand, but in some respects they are inferior to pneumatics.

There are quite a few advantages of a pneumatic device.

-

The quality of the ink layer created by this device is practically unrivaled. The airless method does not always create such an ideal painting.

-

The reliability of pneumatic spray gun parts is very high.It consists of metal elements that are not so afraid of wear and corrosion, that is, it is even difficult to break it. But the power tool is often made of plastic, which requires no explanation regarding strength.

-

The device is considered universal, you can change its nozzles, spray materials with different viscosity characteristics. Electric models have replaceable nozzles, but with regard to the consistency of the mixture, they are more capricious. It is possible that too liquid composition will leak, and very viscous - it is difficult to spray.

The pneumatic spray gun also has disadvantages.

-

A compressor is needed for uninterrupted air supply. This can only be called a drawback of the device with a stretch, especially if the compressor is already available. But if a device is purchased in the form of a pistol, and there is no compressor on the farm, it will have to be bought separately. And then such a device will be several times more expensive than an electric apparatus.

-

Experience and customization required from the master. A beginner to pick up a spray gun and immediately cover the surface with high quality and without complaints is too optimistic a scenario. For example, the gun has several controls that control air flow, material flow, and torch width. To accurately calibrate the device, you need to understand its requirements, have a gearbox with a pressure gauge. Only the correct setting of the device will give that very ideal, uniform coverage.

-

Mandatory cleanliness of the air supply. For example, if the air is too humid, if it contains dirt and oils, then defects will appear on the painted surface: spots, craters, bulges. If there is a very important job ahead, a moisture separator (and sometimes even an air preparation unit) is connected between the gun and the compressor. But, frankly speaking, pneumatics in this sense still surpasses the electric tool, which does not come close to this quality bar.

With the main criterion designated as "creating a uniform layer", the pneumatic spray gun is still the most successful choice.

Types

The principle of operation of the device will be the same for all models, regardless of what year they were released, or where the tank is located. And yet, there are different types of pneumatic devices.

High pressure

Marked as HP. This is the first paint spray gun that appeared almost a century ago. For a long time it was considered the most advanced device. But he did not do without drawbacks, for example, he consumed too much air, and the tolerance of paints and varnishes to the surface was not particularly high. The power of the air stream sprayed the paint very strongly, that is, up to 60% of the substance actually turned into fog, and only 40% reached the surface. Such a unit is rarely observed on sale, because more competitive ones have appeared among hand-held devices.

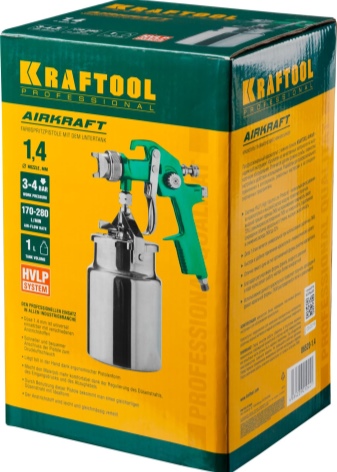

HVLP

This is how high volume and low pressure instruments are marked. This type of spraying is considered to be more environmentally friendly and efficient. Such devices appeared in the 80s of the last century. Their requirements for air supply are higher (350 l per minute), but the outlet pressure is reduced by almost 2.5 times due to a special design. That is, mist formation during spraying is significantly reduced.

These spray guns deliver at least 70% of the paint to the surface. Therefore, they are used today, not being considered a relic.

LVLP

Marked as low volume, low pressure. This category includes advanced spraying devices that are successfully used in professional applications. We developed them to optimize, perfect the painting process, and reduce the requirements for the compressor. The redesigned system requires a minimum inlet air volume of only 150 liters per minute. More than 70% of the paint (or other applied material) appears on the surface. Such spray guns are rightfully considered the most popular today.They are used by both professionals and those who independently solve small everyday tasks.

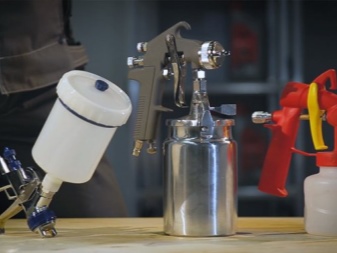

Varieties at the location of the tank

As already mentioned, it can be in different places. Mostly above or below.

With top

It works on the principle of attraction. The sprayed composition itself flows into the channel where the material is fed. The tank is installed on a threaded connection, it can be internal and external. A "soldier" filter is placed at the junction point. The tank itself in such a system is not without its peculiarities: the container is represented by a body with a lid and a vent hole so that air can enter there when the volume of the coloring composition decreases. The tank can be made of both metal and plastic.

Metal is more reliable, but weighs a lot. Plastic is lighter, it is transparent, that is, you can see the level of paint volume through its walls. But with prolonged use, plastic runs the risk of reacting with the components of paint and varnish mixtures, which is why the material is deformed and even ceases to be airtight. The top-cup device is better suited for spraying thicker formulations. One viscosity paint spray better, forming a fairly thick layer. Typically, such models with top tanks are used by professionals who paint cars, pieces of furniture and other surfaces that require a perfect, impeccable layer.

With bottom

To say that such a construction is less in demand would be untrue. The principle of operation of such a device is based on the drop in pressure indicators in the tank as a reaction to the air flow passing over its tube. Due to the strong pressure above the outlet of the tank, the mixture is pushed out and, picked up, is sprayed from the nozzle. This effect, by the way, was discovered by the physicist John Venturi already about 2 centuries ago.

The design of this tank is represented by the main tank and the lid with a pipe. The two elements are connected either by thread or by special lugs fixed above the lid. The cap, fixed in the tube, is bent at an obtuse angle in the center. Its suction tip should point towards the side of the bottom of the tank. So you can use the device in an inclined view, paint the horizontal lines from above or below. Almost all models of spray guns with such a tank are made of polished metal, on average they hold a liter of mixture. They are suitable if you need to perform large amounts of work.

By the way, a little less often, but you can still find spray guns with a side tank on sale. It is called a swivel (sometimes adjustable) and acts in the same way as a top-attachment tool. The composition fits into the nozzle under the influence of gravity, but not from above, but from the side. This is usually a metal structure.

Rating of the best models

There are many ratings, and often the same models appear in them. It is worth dwelling on them.

-

Walcom SLIM S HVLP. Quite an advanced tool that will bring 85% of the paint to the treated surface. The spraying system in it is considered optimized, the minimum volume of air consumption is 200 liters per minute. In the basic configuration, there is a plastic case to store and carry the spray gun as comfortably as possible. There is also a regulator equipped with a pressure gauge, oil, a wrench and a brush for cleaning are present in the kit. It costs an average of 11 thousand rubles.

- Anest Iwata W-400 RP. It has a very fast transfer of the composition to an object or plane, a high level of compressed air consumption (about 370 liters per minute), as well as a maximum permissible torch width of 280 mm. Packed in cardboard, sold with a filter for the applied formulations and a cleaning brush. It will cost 20 thousand rubles.

- Devilbiss Flg 5 RP. It is in great demand among inexpensive models. 270 liters per minute - the level of compressed air consumption. Torch width - 280 mm. The body is made of aluminum, and the nozzles with a needle are made of stainless steel.It interacts well with any type of paint and varnish material, except those made on a water basis. Does not have a case for storage or transportation. It costs about 8 thousand rubles.

- Walcom Asturomec 9011 HVLP 210. Of the not very expensive devices, it is considered effective, and therefore the preferred model. The basic configuration includes retaining rings, gaskets, springs, air valve stem, and cleaning oils. Such pneumatics will cost 10 thousand rubles.

- "Kraton HP-01G". A good option for an unassuming home renovation, as it costs only 1200 rubles. The body is made of durable aluminum alloy. The container with paint is connected from the side, which helps not to obstruct the view and is suitable even for beginners. The easily adjustable torch shape, the convenience of lying the refueled pistol in the hand, and the high throughput of the nozzle are also attractive.

- Jonnesway JA-6111. Suitable model for a wide range of painting jobs. Suitable for all types of varnishes and paints. It sprays well with minimal cloud, has quality components and promises a long service life. It will cost about 6 thousand rubles.

- Huberth R500 RP20500-14. It is considered an excellent option for painting a car, it works great with structures of a complicated shape. Equipped with a durable metal body, grooved, very comfortable handle, a plastic tank that allows you to control the level of paint volume. It costs a little more than 3 thousand rubles.

The most preferred spray guns for the buyer are made in Italy, Germany. But Russian devices are not ignored either.

How to choose?

The first rule is to clearly define the task for which the spray gun is purchased. And you also need to understand what are the nominal viscosity indicators of the composition that will be filled into the gun. You also need to study the build quality of the tool and the type of spray.

Let's take a look at what needs to be assessed when choosing a device.

-

Build quality. This is perhaps the most important point. All structural elements should fit as tightly as possible to each other: if something dangles, staggers, this is already a bad option. There should also be no gaps and backlash in the device. And this applies to absolutely all types of spray guns.

-

Checking the contour of the spray gun. Not all points of sale provide the client with such an opportunity, but it is nevertheless a mandatory point of inspection. The tool must be connected to the compressor, pour the solvent into the tank (and not varnish or paint). The check is carried out on a regular piece of cardboard. If after spraying a spot of even shape is formed, the product is suitable for use. It is on the solvent that this test is made, since the spray gun remains clean after application.

-

Assessment of the ability to produce the maximum volume of compressed air. The minimum indicators of this parameter will not make it possible to spray the paint and varnish composition with high quality, which is fraught with smudges and other defects.

It will be useful to talk to a consultant: he will tell you which models are more suitable for using oil paint, which ones are taken for facade work, which ones are designed for small volumes, and so on.

How to use?

The instructions are simple in theory, but in practice, questions may arise. The process needs to be worked out.

Here's how to use a spray gun.

-

Before painting, you need to conditionally divide the painting plane into zones: determine the most important and slightly less important ones. They begin with the latter. For example, if this is a room, then paint starts from the corners. Before starting the operation of the spray gun, it is taken to the side, to the very edge of the surface, and only then the device is started.

-

Keep the device parallel to the surface, without tilting, maintaining one specific distance. Painting will be done in straight, parallel lines, moving from side to side. The stripes will be with slight overlap. You need to exclude all arcuate and similar movements.

-

You can check whether the paint is well applied at an oblique angle. If an unpainted fragment appears, you need to immediately paint over the void.

-

Ideal if painting is done in one go. Until the entire surface is painted, the work does not stop.

-

If you paint indoors, you need to provide ventilation in it. And on the street you need to paint in places protected from the wind.

Ceilings are especially difficult to work with. The spray gun must be kept at a distance not exceeding 70 cm from the surface. The jet should be applied exactly perpendicular to the plane. To apply the second coat, let the first dry. The ceiling is painted in a circular motion, without lingering in one segment.

The spray gun, like any technique, requires care. You need to pull the trigger, holding it in this state until the composition pours back into the tank. The component parts of the device are flushed with a solvent. Then the solvent is poured into the tank, the trigger is pressed, the spray itself is cleaned. It is enough to wash the remaining parts with soapy water. The air nozzle can also be cleaned with a toothpick. The final stage is the use of a lubricant recommended by the manufacturer of the spray gun.

Adjustment, tuning, cleaning - all this is necessary for the device, as well as careful handling. There are a lot of types of spray guns, some are suitable for servicing anti-gravel cylinders, and for a variety of painting works. Some models are simpler, and it is better to limit their functionality so that they last longer.

But few would argue that these devices have simplified painting processes, automated them and made them more accessible to a wide range of users.

The comment was sent successfully.