All about metal workbenches

Metal workbench - a special table, the surface of which is designed for processing materials. The table is equipped with a number of accessories, through which it is possible to facilitate work and speed up the process of completing the task. Very often there are various vices, stops or other devices that can be useful in the design. In addition to the countertop, the workbench also has shelves and drawers for documents or tools.

The advantage of such a table is the ability to adjust the dimensions in such a way that the master is comfortable.

On average, the height of the structure is 80-90 cm, and the width reaches 100 cm for ease of operation. The length depends on the individual preferences of the master.

Peculiarities

Metal or aluminum workbenches are distinguished by their strength characteristics and long service life. Depending on the conditions in which the table will be used, the models may have additional parameters. Let's consider the main ones.

- Tabletop material. Mostly the table is made of iron sheets. The surface is covered with galvanized metal to prevent deformation. The thickness of the table top can be varied from 24 to 30 mm.

- Permissible tool load. If we talk about the serial production of workbenches, then this figure lies in the range from 300 to 350 kg. Individual tabletops are capable of accepting loads of up to 450 kg or more.

- Shelf load. The average figure is 20-30 kg, but if desired, it can be increased up to 50 kg inclusive.

- Protection. In some models, special locks are provided on the pedestals, they increase the safety of storing documents or tools.

Also, tabletops can be additionally equipped with holders, hooks or screens. All this only improves the workflow and increases the efficiency of material handling.

Species overview

Today manufacturers produce various types of tables. Workbenches differ in different categories, including the shape and material of the countertops, their ability to withstand maximum loads, and more. The most popular is the classification by design... Workbenches in this case divided into the following groups.

Non-bollard

Great option that can be placed in a small garage... The design of the table is simple, this was achieved due to the lack of overall pedestals. It should be noted that the table can be folded and the legs can be adjusted. If necessary, you can purchase model complete with drawers.

Single-column

They are distinguished by reliable assembly. Workbench construction reinforced with table topweighing up to 100 kg. The surface of the table is comfortable, additionally there is a cabinet with drawers that slide out. They may have different heights, which allows them to be used for different purposes. Also, some models have shelves instead of drawers. If desired, you can lock the curbstone with a central lock.

Double bollards

The maximum weight of such a model is 115 kg. The design provides for the use of two driver boxes. They have different heights and can be equipped with locks. The maximum load per drawer is 30 kg.

There are other models that have their own special functions.

Accessories

In metal workbenches, additional accessories may be provided to facilitate work and improve the quality of material processing. Among the equipment that can be included in the kit, there are:

- built-in panels;

- block equipped with sockets;

- lamps for illumination of the table top;

- tool holders;

- shelves;

- vice.

Some models equipped with hooks, which allow you to keep the required number of tools at hand and not constantly climb into drawers or on shelves after them. Such accessories are excellent assistants to the master, they increase the ergonomics of the workbench design and increase the working space.

How to choose?

For most, the garage is a second home in which you can carry out various experiments and build entire structures. Therefore, they often approach the arrangement of such an effective space with responsibility.

Particular attention is paid to the purchase of a workbench. In this case, you need to consider several criteria that will help you get a reliable table. First of all, you need decide on the goalfor which you plan to use the table. Usually, its acquisition is conditioned by the need to carry out the following processes:

- support of the vehicle and its technical inspection;

- locksmith or repair work;

- correction of defects in various materials;

- quite often workbenches are used to develop their own hobby.

The question that arises when choosing is material of manufacture. The most popular are metal tables, as they have an increased service life and high strength indicators.

The disadvantage of a wooden workbench is poor assembly and short service life. On the surface of such a table, it will not be possible to process complex metal elements, since the tree simply cannot withstand the loads that will be applied to it. The frame of such tables is made of oak or beech, additionally reinforcing it with self-tapping screws, anchor bolts.

Despite the low price of wooden tables, which is significantly lower than that of metal options, such workbenches have many disadvantages. Among the common ones are:

- the inability to perceive impressive loads;

- reduction in the service life of the frame in the case of increased use;

- susceptibility to decay and cracking of the countertop surface;

- lack of the required area to accommodate several types of equipment;

- deformation of a wooden surface under the influence of chemical agents, which include paints, solvents, oils;

- high risk of fire hazard if chemicals are located near the table.

If you plan to handle a large amount of material or often spend time in the garage, you should give preference to metal workbenches. They will cope better with the task at hand and will help to achieve effective work.

To assemble such a table, you will need special equipment, as well as certain skills in working with metal structures. The fact is that the connection of some elements is ensured by welding, so it will be necessary to provide for this moment.

Metal workbenches have high indicators of structural strength, look stylish and can last a long time. Yes, they are expensive, but this cost justifies itself. The advantages of metal structures include the following factors.

- Long service life reaching 50 years or more.

- A wide range of models and various equipment configurations. Manufacturers regularly release new workbenches, offering customers both standard and versatile or professional, designed for a narrow specialization.

- A wide range of functions. With the help of a metal tabletop equipped with various tools and boxes, the master will be able to perform any type of work, which includes turning, grinding or cutting.

- Mobility.Some models can be disassembled, allowing for more garage space if required. Also, the craftsman can equip workbenches with hooks, shelves or other elements.

- Resistant to deformation. The surface of the table is not damaged, does not bend and is not covered with scratches during operation.

Metal workbenches versus wood structures do not require careful maintenance... The surface is resistant to various types of impact. It does not rust and does not require regular painting.

Dust or chips remaining after processing the material can be removed from the table surface in a matter of seconds.

How to do it yourself?

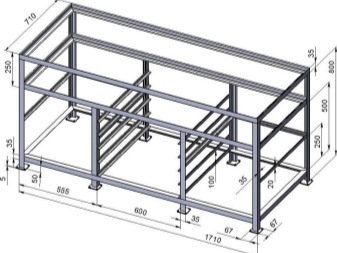

It is not necessary to order expensive workbenches to equip garages with them. If desired, such a table can be assembled at home using a drawing and suitable materials and tools. For this you need:

- Bulgarian;

- overalls;

- roulette and level;

- devices for the installation of fasteners;

- steel profiles;

- strips and sheets of steel;

- wooden boards and plywood;

- fasteners;

- dye.

The procedure for making a homemade metal workbench is complex, therefore it will take time and a responsible approach. It is carried out in several stages.

- First, you need to cut the material into separate elements, taking into account the dimensions. So, for example, a frame is created from shaped pipes, the corners are used to form stiffeners, which will strengthen the strength of the structure. Guides will be made from steel strips installed on the sides of the table. Plywood is intended for the assembly of boxes.

- The next step is to weld the frame. First, the pipes are welded, then the corners, on which the tabletop will subsequently be laid. Also, this stage includes the manufacture of the main frame for the countertop.

- The third stage is the creation of boxes. It will be necessary to determine in advance the type and amount of equipment that will be used in the future. This is necessary in order to select the number of boxes and their height.

- Next, the wooden boards are laid in the frame of the table top. They must first be prepared by processing and laminating the surface.

- The penultimate step is to attach the steel sheet to the wooden countertop. It can be welded if possible.

- The last step is to install the boxes. It is desirable to paint them.

Metal workbench - a reliable type of industrial furniture, characterized by durability and ease of use.

The metal workbench is presented in the video below.

The comment was sent successfully.