All about the cycle

Many novice craftsmen want to know what a cycle is, what work can be performed with such a tool. The main field of application of this tool is surface treatment of wood and parquet, ship modeling, but it is suitable only for fairly delicate work. It is worth talking in more detail about how to choose a manual scraper, how to use it and do it yourself.

What it is?

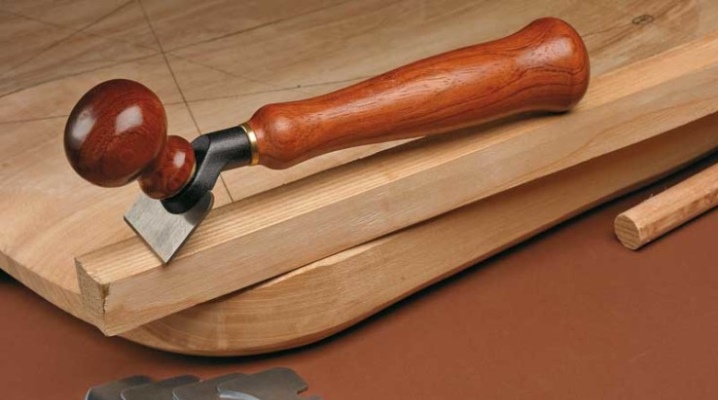

A scraper is a hand tool, which is a miniature scraper with a handle and a cutting sharpened blade, positioned perpendicular to the surface to be cleaned during operation.

The miniature tool fits comfortably in the palm of your hand. Depending on the width and shape of the blade, flat or volumetric surfaces of objects can be processed. The most widely known scraper is the tool used in the installation of parquet flooring. Their distinctive feature is the removal of the minimum layer from the surface of the wood - the shavings have a thickness of no more than 0.04-0.08 mm.

Other jobs can be done with loops.: prepare skis, snowboards, surfboards, create boat models. Allocate joinery and parquet cycles with different scopes. In addition, there are curve options - without a handle. The modern version of the cycle is a mechanized tool, with the help of which the old covering is removed from the parquet floors.

When using such a scraper, the work proceeds much faster and more efficiently.

The main material for the manufacture of scraping joinery tools is carbon steel. The standard knife thickness reaches 1.5 mm, its sharpening angle is 45 degrees, like a plane. For parquet varieties, steel grades 7HF, 9HF, U7GF, U8 and others are used, phenolic compressed masses or natural hardwood (oak, beech, hornbeam, maple, ash) are used for handles. In this case, the sharpening of the blade is performed at an angle of 25-30 degrees.

Glass cycle used for cleaning aquariums, window surfaces. In fact, in this case, they are classic scrapers that mechanically remove dirt.

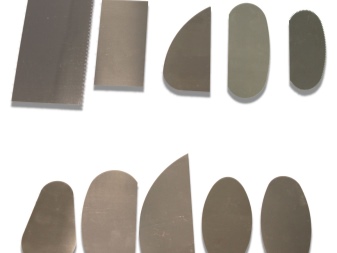

The shape of the tool blade can be:

- rectangular;

- triangular;

- trapezoidal;

- "Swan neck";

- ovoid.

When working with wood, scraping is carried out exclusively in the same direction as the fibers of the material. This avoids the formation of burrs and other defects on the surface.

Purpose of the tool

The main purpose of the scraper hand scraper is to scrape the surface of the material... It works a bit like sandpaper, but performs tasks with greater intensity. When fitting miniature parts, it is this tool that allows you to achieve the most snug fit. It is convenient for them to work on a limited surface area, to remove thin layers of wood in the corners - where a special machine cannot reach.

Until recently, the question of why a cycle is needed was mainly asked by carpenters or owners of parquet floors. Today the application of this tool is much wider. For example, handleless patterns are still used today in small carpentry jobs.

Curly loops widely used for ship modeling when creating various elements of complex shapes. Such devices are even sold only in specialized stores, focused on extremely painstaking work with the material.

Although the cycle for parquet is considered an insufficiently effective tool, sometimes it is the only way out when restoring old parquet floors in conditions that do not allow the use of machine processing.

Joiner's cycle needed for wood processing. It can also be used to remove adhesive from material joints. It is irreplaceable when processing wood with a complex, multidirectional fiber structure. Unlike grinding tools, scraping does not lead to the formation of fine dust that clogs the pores of the material. In its modern design, this tool is absolutely irreplaceable even for large volumes of work.

Cycling with hand tools is also in demand in skiing. This is where their ability to cut the thinnest layers of material without deeply damaging its structure becomes especially important. With the help of cycling, you can easily bring fiberglass skis back to life, add speed characteristics and glide smoothness to them.

With the help of a cycle, you can easily clean off old paraffin and grease, without risking damage to the structure of the ski itself.

How to choose?

When choosing a cycle, it is worth considering that the main criterion in this is instrument purpose... For example, for parquet and joinery models, even the sharpening angle will be different. Don't rely on promotional promises either. Electric cycle most likely it will turn out to be an ordinary surface grinder, which has nothing to do with the classic scraper. Of greatest interest to a craftsman familiar with carpentry are the following options for hand scrapers.

- Rectangular. They are carpentry, for smooth surfaces. The standard dimensions are 50 × 100 mm.

- Shaped or "with a swan neck". They are used when processing round or curved parts, for wood carving, creating profiles.

- Painting. Used to create original decorative patterns on plaster. Such cycles have a triangular or heart-shaped tip and are easy to use. They can also be used to scrape off the paint layer from vertical and horizontal surfaces.

- Parquet. On a curved handle, with a rounded leading edge and a mandatory burr. These tools are mounted in special two-handed pads to help you work faster and safer on large areas on a flat surface.

Don't assume that the cycle is cheap. Indeed, inexpensive plastic painting options with replaceable blades will cost 1,000 rubles or less. A good two-handed model from a well-known brand will cost 7 times more. Curly options without a handle can be bought in sets from 1,500 rubles, all-metal ones cost about 3,000.

It is not recommended to choose cheap cycles from Chinese online stores. The risks of purchasing a low-quality product here tend to be 100%.

How to do it yourself?

Homemade loop removes the surface layers of wood just as well as its industrial counterpart. Of course, in the age of power tools, their hand-held counterparts fade into the background. But if you study the issue more closely, you can understand: The cycle is still relevant for the block laying of inlaid parquet and other works that require care and attention to detail.

To do it yourself, just follow the simple step-by-step instructions.

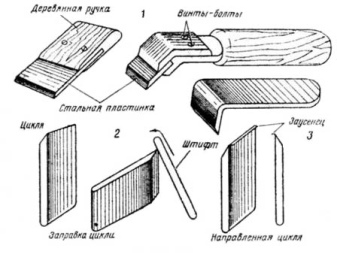

- Prepare materials. The minimum set is an old knife blade or saw blade, pallet board, protective impregnation and sandpaper for grinding. The selected piece of wood for the handle should be wider than the metal piece and long enough to fit comfortably in the palm of your hand.

- A triangular or trapezoidal blank is cut from metal... The front edge is sharpened at an angle of 45-50 degrees with a cut at 100-110 degrees, a burr is formed on it - a burr for scraping. Better to use a diamond tool.

- A tool handle with a wide base is drawn and cut out of a wooden blank. The cutting element will be mounted in it. The surface is sanded with a hand or electric tool. Finishing is done with 100 grit sandpaper.

- With a caliper you need measure the thickness of the future blade... Make a cut on the bottom flat edge of the tool. Its depth should be no more than 1/2 of the blade height

- Insert a loop into the resulting hole... If necessary, secure the cutting part additionally.

- Cover the handle protective and decorative composition.

Following these instructions, every home craftsman will be able to create a simple cycle with his own hands from the most affordable materials. Besides, simplest scraper for wood can be made from a triangular metal blank with a welded handle and a wooden tip. The triangular tool is sharpened on all sides with a slope to one side. The corners are aligned. Further, the base is welded in the center, a wooden holder is placed on it - and the cycle is ready to work.

In the next video, you can visually familiarize yourself with the instructions for making a cycle with your own hands.

Thanks! I found out what this thing is.

The comment was sent successfully.