Sclerometers: features and tips for choosing

A sclerometer is a device that makes it possible to assess some of the characteristics of various materials by the method of damage. The first serious methods of testing the strength of metals and minerals appeared in the 19th century, they were based on making cuts with sharp objects and files. Over time, assessment methods have become more sophisticated and more accurate.

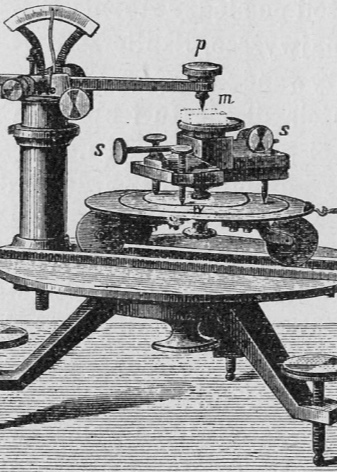

The first prototype of a modern sclerometer was a device created by the German physicist Seebeck in 1833.

Purpose and scope

Now the term "sclerometer" refers to any apparatus with which the studied surfaces are scratched, thereby checking such indicators as:

- the ability to resist the impact of a harder object (hardness);

- the ability to restore its structure after exposure (plasticity);

- ability to resist abrasion (wear resistance).

In particular, this tool is a tester for the hardness of a material such as concrete, therefore it is also called the “concrete hammer”. The area of use for this tool is the construction industry.

The tool allows you to determine the quality of materials from which various structures, buildings and structures are erected. This is necessary to study their integrity, timely prevent destruction and exclude the appearance of victims.

Types and principles of work

The modern construction market produces three types of sclerometers: mechanical, electronic and ultrasonic. The first two types perform measurements according to the shock-impulse method standardized by GOST. It consists in determining the length of the bounce of the built-in mechanism, which transmits the impact to a hard surface.

Mechanical instrument has an elongated shape, similar to an enlarged ballpoint pen. An impact firing pin with a spring is mounted inside it, and outside there is a scale that displays the pressure withstand by the surface. This is the simplest of the existing devices, which has a significant error and a small range of applications.

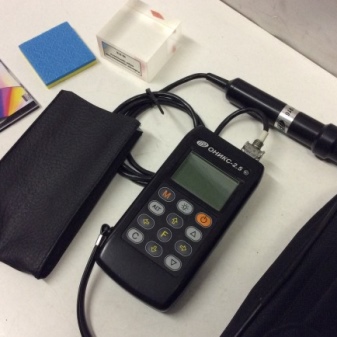

Electronic apparatus outwardly similar to a mechanical one, but it has a much smaller size and is additionally equipped with an electronic device. This device displays the measured values taking into account the temperature error, and operates on only two batteries. The electronic device has a smaller error and can be used not only on concrete, but also on composite, metal, brick and marble surfaces.

Ultrasonic type calculates the strength of materials by the time and speed of the emitted wave. The body of the tool is made of plastic, on the front part there are keys and a display, and on the side there are two contacts. Like the electronic one, this device has the function of saving the measurements taken and runs on batteries.

Peculiarities

Each type of apparatus has its own characteristic features.

For ultrasound models, these are:

- the ability to exchange data with a computer;

- convenient control and configuration of the device using buttons and interface;

- shutdown with a long break in use;

- memory for saving measurements;

- sounding the process of work;

- automatic change of waves;

- the ability to search for defects and cracks.

Distinctive features of electronic models are:

- ability to record measurements;

- the ability to transfer indicators to a PC;

- sorting function of measured data;

- change in the direction of the impact.

It should be noted that electronic models have an optimal price compared to alternatives.

The specificity of mechanical models is as follows:

- the ability to work at a temperature of - 40 °;

- low cost;

- high error;

- great weight.

Characteristics of modern models and tips for choosing

Any modern model of a tester for the strength of solid materials facilitates the processes of all areas of construction work. With the help of a small device, it is easy to carry out quality control even on masonry without serious damage.

The main characteristics of all types of sclerometers include several parameters.

- Measurement error... The largest error in mechanical models. It is usually not indicated, but often reaches 20%. And also mechanical models have the highest frequency of breakdowns. For electronic, this figure is 5%, and the smallest for ultrasonic equipment: 1%.

- Working strength range... For mechanical devices, it is 60 MPa, for electronic devices - 100. For ultrasonic devices, the interval varies in time and speed.

- Comfort of use... It is less convenient to use a mechanical device due to the lack of preservation of results and a large weight (1 kg).

- Price... In this indicator, the opposite is true: the most expensive is an ultrasonic device.

If you make a rating of the best device, then the leader will undoubtedly turn out to be ultrasonic, since it is ahead of others in all respects, except for the price.

It is best to choose the latest models of popular manufacturers of measuring instruments for purchase. The top companies producing quality products include Interpribor with Onyx devices, Condtrol with the same name, as well as Schmidt Hammer and RGK.

For an overview of the IPS-MG4 sclerometer, see below.

The comment was sent successfully.