All about precision miter box

For carpentry work, many devices have been invented that improve the accuracy of processing. One of them with an interesting name is a miter box intended for end machining of parts and obtaining smooth, neat joints. With the help of this tool skirting boards, door and window frames, moldings, cornices are processed - everything where there is an angle connection.

Views

The simplest miter box is a V or U-shaped box with open ends and a slot in the side walls made at a certain angle. The box is made of plastic, wood or metal profile. The cuts are made in 15 ° increments, which is enough to obtain the required angular cuts. Sawing is done with a saw without setting with fine teeth, the so-called slotting. In this case, it is best to use a butt saw, since the steel plate on the back of the tool gives it additional rigidity and at the same time serves as a limiter for the cutting depth.

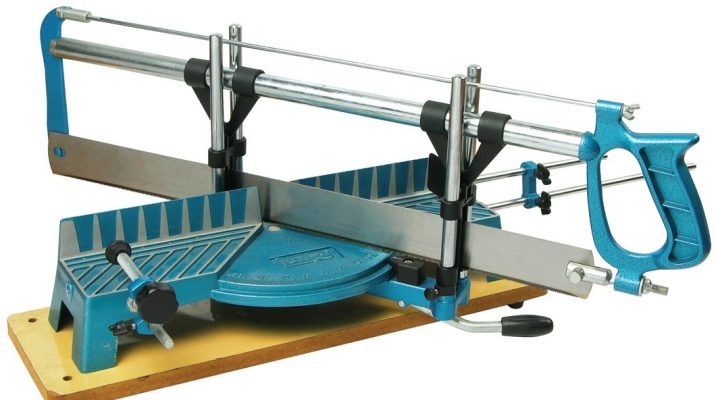

For processing parts on an industrial scale, it is more convenient to use a rotary device with a hacksaw or a precision miter box. A slotted plate and a special replaceable saw, mounted on a rotary disk-shaped base with a graduation applied to it to determine the correct sawing angle, allows you to cut at any desired angle. For some models of a precision miter box, the angle of inclination relative to the surface of the workpiece can also change to obtain an end cut at an angle in two planes at once.

Manual processing is suitable for small-scale work, but if you need to perform the same type of cuts in a large volume, then an electric precision miter box is used. The unit is a circular saw fixed on a rotary bed with the ability to change the angle of inclination for facing workpieces.

In addition to a simple and rotary miter box, there are tools designed for one type of work. These are devices for obtaining dovetail joints and straight spikes.

Instructions for using the miter box

Initially, the miter box was invented for working with wooden products, but now, having selected the correct cutting blade, with the help of the miter box, you can trim materials of various hardness from metal to foam, getting neat cuts.

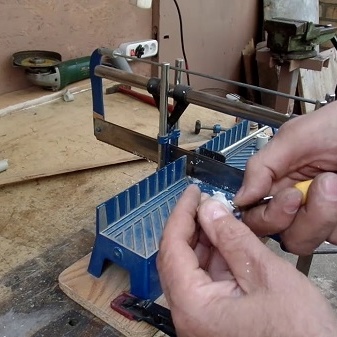

Working with a miter box is not particularly difficult, but a minimum skill is still needed. The work algorithm can be represented as a sequence of several operations.

- The base of the fixture is attached to the work surface using a clamp or self-tapping screws.

- Marks are made on the workpiece to indicate the location of the cut.

- The workpiece is fixed on the miter box platform with a mark opposite the slot in the side plate.

- The degree of the cutting angle is set and fixed so that the saw moves only in one plane.

- The end is cut.

When working with the device, it is important to take into account several nuances and not forget about the well-known rule, according to which you need to measure seven times and cut off once.

- What angle should be obtained - internal or external. To obtain an inner corner, the back of the workpiece is made longer, if an outer corner is needed, then the outer side of the part will be longer.

- Remember that any corner has two rays - right and left, so the slices should be positioned so that a solid line forms when they are joined.

How to choose a miter box

When choosing a miter box, you need to pay attention to the material from which the device is made, and the number of options for the set cutting angles. Conventional miter boxes are made of wood, plastic or metal and are easy to make yourself. The saw can be included in the kit or it can be selected so that the blade fits into the slot without effort. For non-professional use, a simple miter box is enough, which allows you to cut sections at an angle of 45 and 90 °.

Precision miter boxes can have either a plastic or a metal base and are equipped with a bow or bow saw. Since the device can handle materials of different hardness, it is possible to replace the saw blade with a blade suitable for a certain type of material, since it is impossible to work with metal and foam with one saw. The hacksaw should be quite tough, thin and with fine teeth. The blade length, suitable for a particular job, is selected in the range from 29 to 60 cm.

Where a high accuracy of fitting the joints of the product and obtaining the ends of a non-standard shape is required, it is better to choose a device with additional functions: the ability to securely fix the workpiece using a clamp or special devices, a fixed inclination of the cutting blade applied to the platform with a ruler to obtain parts of the same length, a limiter cutting depth.

And there are also moths with a movable carriage, convenient in that there is no need to move the workpiece itself. Tilted carriage models are used to produce cuts of complex geometric shapes. Due to the fact that the miter box is a fairly simple tool in terms of configuration, no spare parts are provided for it. Of all the parts, only the saws are replaced.

In the rating of models of precision mowers, the most famous Fit Profi and Champion 180, as well as the model of the Zubr brand. The miter box under the Stayer brand is in good standing with consumers.

In the next video, you will find a detailed review of the Gross 22759 rotary miter box with a hacksaw.

The comment was sent successfully.