What kind of stone cutters are there and how to choose them correctly?

Nowadays, different types of natural stone and its artificial counterparts enjoy record popularity as building and finishing materials. In addition, materials such as marble and granite are widely used by sculptors as well. It should be borne in mind that stone processing requires special equipment with appropriate performance characteristics. That is why it is worth analyzing what industrial, household and professional stone cutters are and how to choose them correctly.

What it is?

All modern stone cutting machines, regardless of their type and purpose, are technological equipment designed to process hard materials with maximum precision.

Such machines allow you to cut stone so that in some cases the joints between the individual elements will be practically invisible.

The achievement of such outstanding results is primarily due to the rigid design of the machines, which in the classic design consist of the following key elements.

- Frame - the basis of all equipment, the quality and geometry of which largely depends on the accuracy of work. It is this parameter that is one of the defining ones when choosing a model of a stone cutting machine. Experienced specialists in the process of machine tool inspection focus on the rigidity of the frame, checking it for deflections under the influence of different forces.

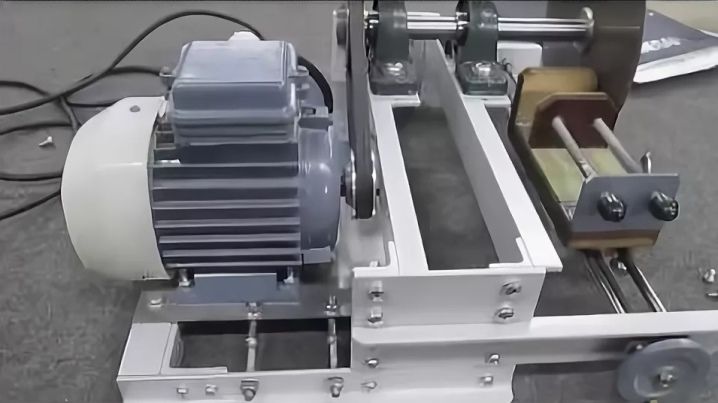

- Power point. In the overwhelming majority of cases, we are talking about electric motors connected to a network with a voltage of 220 or 380 V, depending on the type of stone cutting equipment. A predictably important characteristic of any model will be the power of the motor that is installed on it. And in this situation, everything is extremely simple - the higher the indicator, the more efficiently the equipment will work and the larger the stones can be processed on it.

- Transmission... In this situation, we are talking about a unit that is responsible for the transfer of torque from the power unit (electric motor) to the working tool (cutting discs). It is worth noting that machines with a lower and rigidly mounted drive are equipped with a full-fledged transmission. As a rule, this unit is a belt drive, but high-precision machines are equipped with chain and gear mechanisms.

- Work item. The cutting head, called by many professionals a cut, here is a shaft to which, in different ways, depending on the modification, rotation from the motor is transmitted. It is equipped with a special clamping nut designed to fix the cutting discs according to the grinder principle. By the way, on the basis of angle grinders (angle grinders), fairly high-quality and efficient handicraft stone cutters are made. Moreover, devices for fixing such devices can be found on sale, with the help of which they are transformed into the described technique for performing high-precision work with hard materials.

- Auxiliary equipment in the form of a pump, providing the supply of coolant to the cutting element during the operation of the machine. In addition, we can talk about a whole arsenal of additional devices, which, as a rule, are purchased separately as needed and taking into account the peculiarities of the work performed.

Particular attention should be paid to the way the motor is mounted on stone cutting machines.... There are two options, one of which is to locate the drive under the bed. In this case, the power unit itself and the cut are static, and the material to be processed is pushed onto the cutting blade. The second option is to position the motor over the bed. In this case, together with the cutting head, it moves along the guides. This type of equipment is considered safer.

In addition to all of the above, modern models of stone processing equipment may have other structural elements. Often they are equipped with mechanisms that provide automated feeding of the working part or the workpiece for modifications with an upper and lower drive, respectively.

Such systems maximize the safety of equipment operation, since a person will only need to configure and activate the installation. The latter will do all the work on her own.

Views

At the moment, manufacturers present on the market a fairly wide range of stone cutting machines. Taking into account design features, all available models can be divided into the following categories.

- Manual, which can be both mobile (belong to the mini class) and stationary. In this case, we are talking about desktop typewriters.

- With bottom static and top movable drive.

- With vertically and horizontally oriented feed, as well as combined (universal) versions.

- Wirewheels with a diamond component, tape and equipped with diamond discs.

Depending on the configuration, equipment and purpose, the machines are divided into:

- stone splittersused in the production of facing materials, as well as paving slabs and other products with a chipped structure;

- gaugeused in leveling stone slabs;

- detachable, which have received the widest distribution.

Household

As such, stone cutting machines for domestic purposes do not exist. This is due to the fact that we are talking mainly about professional equipment. At the same time, electric tile cutters can be attributed to this category of modern tools. Devices of this class are widely and successfully used in finishing works of varying complexity.

In this case, one of the key points will be the accuracy of cutting the material, taking into account the permissible deviations. In situations with ceramic tiles and porcelain stoneware, this figure is from 0.5 to 1 and no more than 0.5 mm, respectively. When using such mini-machines, it should be remembered that the quality of the work will be reflected in the results of the work and, in particular, the condition of the cut edges:

- shaft grinding;

- clamping nut surfaces;

- cutting disc included in the basic equipment delivery set.

Avoiding chips and maximizing the quality of cuts will allow constant monitoring of the position and tightening of the working element, as well as the settings of the machine. An equally important point is the correct selection of disks.

Professional

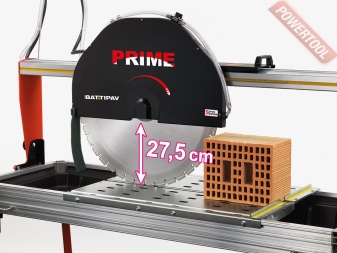

As already noted, the execution of a cut when processing porcelain stoneware allows deviations from the linear dimension within 0.5 mm. Such precision is provided by professional models of stone cutters. An equally important parameter is the power of the equipment, thanks to which a stable 2800-3000 rpm is provided when the machine is operating under load. This performance eliminates the need to process materials, including facing bricks, after cutting.

Many manufacturers do not include discs in the basic set of professional stone cutters. This is due to the fact that experienced specialists independently select the most suitable working parts for the equipment they use in their work.

Manufacturing

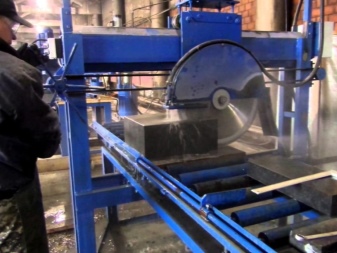

The main characteristic of industrial technology for the processing of hard materials is, of course, maximum precision. In this case, the cut is performed both perpendicularly and at an angle set by the operator. It is worth focusing on the fact that during the operation of such large-sized machines, the error is hundredths of a millimeter and therefore it is considered to be zero. The high quality of the cut is due, among other things, to the inadmissibility of gaps between the facing plates made of natural stone.

Workshop models of machines are equally successfully used in the production of both finishing and building materials. In this case, it is important to take into account the width of the cut itself, determined by the characteristics of the working elements. Predictably, this indicator will be higher for industrial machines, compared to cuts when performing work with simpler samples of equipment. On the other hand, the production machine allows large slabs and pressed agglomerates to be quickly and accurately cut into workpieces of the required size, regardless of the filling.

Popular models

As already noted, stone cutting equipment of various classes is widely represented in the modern market of Russia and other countries. At the same time, in parallel with the model lines of leading domestic and foreign manufacturers, the lists of the most popular models are constantly updated.

Taking into account the numerous reviews, one of the leaders in the ratings can be called the products of the Russian brand "Practice"... According to current statistics, the model 2380 is in well-deserved demand. This unit can handle any stone at 800 watts. The machine is equipped with a working disc with a diameter of 2300 mm, which allows you to make diagonal and oblique cuts with good accuracy. The maximum values for the depth, length and thickness of cut are 25, 500 and 43 mm, respectively. The unit weighs 30 kg and differs from competitors in compactness.

The next hit of sales is the German stone cutter Fubag Master Line 6 Star 660. In this case, we are talking about the optimal ratio of the cost of equipment and its quality. For a relatively low price, the manufacturer offers an 800-watt machine weighing just under 30 kg. At the same time, the cutting depth reaches 50 mm, and its length is 0.6 m. One of the important features of the model is the equipment of the equipment with a powerful fan, which significantly increases productivity.

Another very interesting stone processing machine is offered by a company from the United States. Hammer... I mean the PLR 1200 HammerFlex model, one of the clear competitive advantages of which is its affordable price. At the same time, for relatively little money, you can purchase a device with a capacity of 1.2 kW (3,000 rpm). A diamond cutting disc with a diameter of 230 mm is used as a working tool, providing a cutting depth of up to 36 mm.

Naturally, in the considered segment of the market for specialized tools and equipment, the products of companies from the Middle Kingdom are represented. And in this context, it is worth paying attention to the model DIAM PLK-400 / 2.2... This professional device has a power of 2200 watts. The maximum disc diameter that can be used is 400 mm, resulting in a cutting depth of 135 mm.

How to choose?

Basically, when choosing a machine for cutting stone and other hard materials, several of the most important criteria will be the main ones. On the other hand, it is strongly discouraged to ignore the key performance characteristics of the vehicles in question. This is most relevant when it comes to the selection of a professional tool.

Particular attention should be paid to the following points.

- The purpose of the machine and potential tasks that will be solved with its help... It is worth remembering that not all models of the described equipment are universal. So, some machines have a narrow specialization and are intended, for example, to prepare a stone before its further processing.In this case, one maximally even edge is simply formed, starting from which the sawing (cutting) is carried out in the future.

- The basic performance characteristics of the plant play a key role. Their list includes the depth and length of the cut, on which the maximum size of the workpieces to be processed directly depends.

- Maximum load for which the equipment is designed... It should be noted that even semi-professional models of equipment in this case should have high performance, taking into account what materials they are focused on. Also, a high-quality device should work stably in harsh conditions for a sufficiently long time, including in continuous mode.

- Precision in cutting and other operations... Typically, this parameter appears in technical documentation.

- Hardware settings. The functionality of the stonecutter model is determined by the ability to change such important parameters as the depth and angle of cut, as well as the dimensions of the workpieces at the exit, etc.

- Availability and quality of various protective elements.

In addition to all of the above, it is worth focusing on the condition of the working surface of the machine, as well as the quality of the guides, if any. Another important point is the volume of the coolant tank. This parameter largely determines the performance of the equipment.

It is also recommended in the process of choosing a stone cutter model to carry out a comparative analysis of the performance indicators of all candidates.

The comment was sent successfully.