Profiled sheet machines

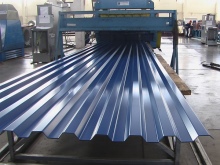

In modern construction, various materials are used, among which corrugated board is especially popular. To create such a material, special machines are used, the features and types of which will be discussed in more detail in the article.

Appointment

Profiled sheet is a demanded material not only for construction, but also for other areas. One of the key advantages of corrugated board is its low price, which is explained by the simplicity of manufacturing products.

Besides, products made from this material are distinguished by high indicators of reliability and durability. The production of profiled sheet is carried out using home-made and mechanized equipment - machine tools.

Any unit works according to a typical scheme. At the very beginning, the flat steel sheet is introduced into a system of rolls, which subsequently shape the billet into the desired configuration. As a result of the operation carried out, it is possible to give the flat steel sheet the desired geometric shape. The technology of broaching rolled steel is used in most models, regardless of their type.

Equipment for the production of reliable profiled products is installed in spacious rooms in order to provide access to the structure from all sides.

Views

For the manufacture of a profiled sheet, different units are used - from manual to fully automated. It is worth considering in more detail the features and characteristics of popular machine models.

Mechanical

Such machines are considered the most simple and demanded. The equipment is suitable for equipping small workshops and private farms. The advantages of the mechanical unit are its compact size and ease of control.

A properly configured handheld device is capable of handling both single blank sheets and rolls. The thickness of the material that the machine can handle must be no less than 0.4 mm and no more than 0.6 mm, the maximum width is 2 meters.

Advantages of a manual bending machine:

- no need for electricity;

- compact size;

- ease of maintenance and operation;

- the possibility of manufacturing roof elements.

The equipment is started by a person manually. The downside of the machine is low productivity.

However, for a small business, the operation of such a unit will be sufficient to achieve the required production capacity.

Automated

Large lines used in industry. Automated machines are characterized by high productivity rates. To install such equipment, you will need to take into account a number of conditions.

- The room where the machine will stand should be spacious. The area of the room should not be less than 100 m2.

- The floor must have a level concrete surface. Additionally, you need to provide a large gate to bring the equipment inside.

- The machine is designed to handle a large amount of material, which requires a crane.

- The automated unit is powered by electricity. Therefore, it is necessary to provide the equipment with 380 volts of electricity. The maximum allowable power must not exceed 23 kW.

An automated line is a whole complex of equipment, which includes the following elements.

- Roll unwinder. Installed at the beginning of the unit. Designed for unwinding galvanized steel with subsequent supply of material from the roll to the machine.It also regulates the level of sagging of the material, the speed of the profiled sheet.

- The machine on which the profiled sheet is rolled. There are two types - pneumatic and hydraulic. It is the main element of the line mechanism. After the unwinder, the raw material goes to the machine, where, with the help of rollers, the flat sheet is transformed into a profile one.

- Scissors. Sharp and large, designed for cutting sheets to the desired size. To increase the rigidity, the guillotine is installed on the bed.

- Material receiving device. An automatic stacker is provided in the design of the element, which regulates the speed of receiving finished products and forming packs.

- Control system. Provides communication between the elements of the automated line and controls the operation of individual mechanisms.

An experienced operator who has certain working skills should regulate the work of a dimensional machine. It is also worth putting auxiliary workers to help the operator.

equipment requirements

Before buying equipment for the production of profiled sheets, it is worth taking into account the peculiarities of this area.

- The material becomes more in demand during the construction season. If you plan to use large automated machines, it is worth providing storage space for equipment during downtime.

- The room where the machine will stand must have a concrete floor with the most even surface.

- The temperature in the room with the equipment should not fall below 4 degrees Celsius. If the machine is automated, then the temperature during operation of the unit should not be lower than 10 degrees.

- In the room, it is necessary to provide a place where steel in coils or blanks will be stored.

- The machines should be located so that the operator has access to the main systems and components in the event of equipment breakdown or failure.

- Unwinding devices of automated machines should be located near the storage of raw materials.

If the room does not provide a place for storing material, you can organize a warehouse in an adjacent building.

Choice

When choosing a machine for a profiled sheet, the following factors must be taken into account.

- Performance. If you plan to produce small volumes of material, you can give preference to manual equipment.

- Dimensions. Manual machines are compact in size, automated ones, on the contrary, require large areas for placement. This point also needs to be taken into account.

- Price. Financial capacity is a key factor in determining the choice of the right machine.

- Functionality. Here you should not run after modern models with a large set of additional options. It is better to give preference to machines capable of producing one type of product. This will speed up production and save on equipment maintenance.

Additionally, it is necessary to provide for the purchase of equipment for the machine. It should be as reliable and secure as possible.

A machine for the production of a profiled sheet is equipment without which it will not be possible to obtain a workpiece of the desired shape and size. Therefore, it is worthwhile to carefully study the characteristics of the unit and decide which device is suitable for work.

For profiled sheet machines, see the video below.

The comment was sent successfully.