What is corrugated board and how to choose it?

Decking is a reliable and versatile material that is popular with developers. It is suitable for roofing, wall cladding, partitions and fences - all you need to do is choose the right type of steel sheet according to the task at hand.

What is it and why is slate better?

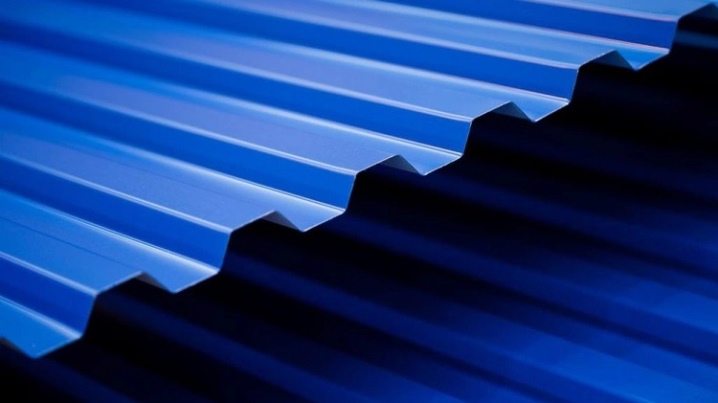

The material is a metal sheet with a corrugated surface. It has pronounced stiffening ribs that run along its entire length. This allows the profiled sheet to withstand increased loads. Steel sheets differ in profile shape and coating material, which affects the characteristics and determines the scope of application.

Often there is confusion between the two names - professional flooring and professional sheet. In a global sense, it is the same sheet material with a profile obtained by cold rolling. However, often the word "profiled sheeting" is understood as the roofing, and the name "profiled sheet" is used for products that will be used for the construction of partitions, fences, wall cladding. It can be concluded that the differences lie in the characteristics.

As a rule, the following indicators are taken into account.

- Rigidity. For the roof, more durable sheets are needed that can withstand a serious load - the effect of the wind, the weight of the snow in winter. With this in mind, the profile height should be at least 35 mm.

- Soundproofing. A material with a stiffer profile eliminates loud noise during heavy rainfall.

- Processing features. Due to its higher strength, the corrugated board is less susceptible to bending, so it is easier to make a fence from a corrugated sheet. It can be given any shape without much effort.

In any case, the material in the store can be named differently, so it is better to look at the labeling - there is all the necessary information that will help you find suitable products.

Decking has gained massive popularity relatively recently. Previously, slate was widely used as roofing, but you should not return to it.

There are several reasons why you should choose a corrugated board if you are planning a roof renovation.

- Ease. The slate has a weight of about 9 kg per m2. Steel sheet - on average 4-5 kg, depending on the type of profile. It is obvious that with light material, installation work will be faster, and it is also easier to transport it.

- Strength. Although slate can withstand horizontal loading well, it can crack when bent or struck. Also, the material will crack from uneven laying and may break if stepped on while cleaning the chimney or during any other work that needs to be done on the roof. The corrugated board calmly withstands the weight of a person and is resistant to impacts.

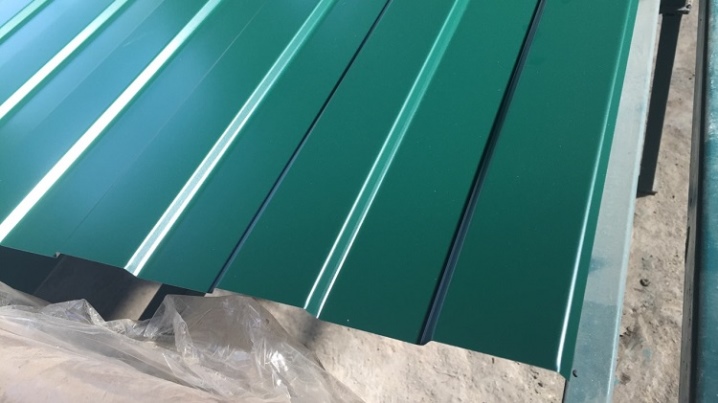

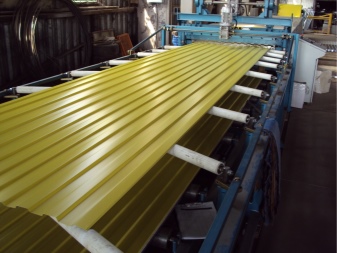

- Aesthetics. Standard slate gray looks inconspicuous, and color slate does not differ in brightness of colors and a variety of options. When buying corrugated board, you can choose any tone from the RAL palette, and some brands also offer branded shades. In addition, the coating can be glossy or matte, it does not fade in the sun.

- Features of operation. Slate absorbs moisture, which leads to the appearance of moss and the gradual destruction of the material.In addition, dust accumulates abundantly on the porous surface, so you will have to constantly clean the roof to make it look neat. Such problems do not arise with corrugated board, and it is not difficult to take care of it - you can water it with a hose to wash away the dirt.

- Fire safety. Although slate does not burn, in the event of a fire, it begins to "shoot", creating sparks, which can lead to the appearance of new fires or cause injury to people. The corrugated board does not support combustion.

For the price, both materials are quite affordable, although the cost of metal sheets can vary, depending on the characteristics. Nevertheless, the performance of the corrugated board speaks for itself. This material will make a durable and beautiful roof.

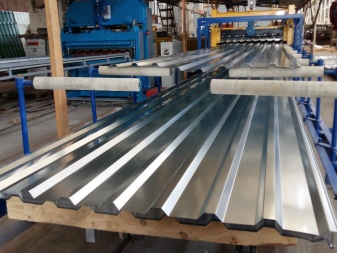

How are decking made?

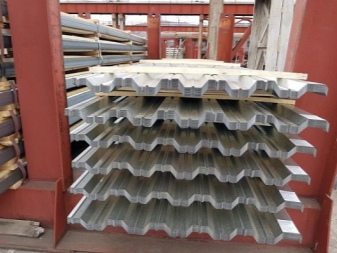

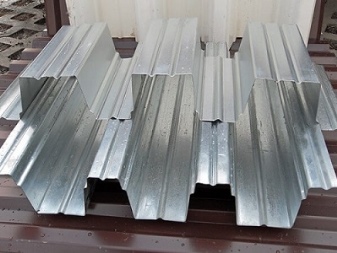

The production of material is almost completely automated - this allows you to receive sheets in large quantities and makes them available to buyers. For the manufacture of profiled sheets, the method of cold rolling is used. Profiling is done in one of two ways.

- With one-step rolling of all corrugations. Such equipment requires less floor space and allows you to optimize production processes.

- With consistent rolling. This method minimizes the likelihood of scrap on metal products.

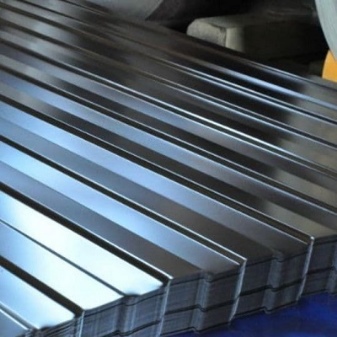

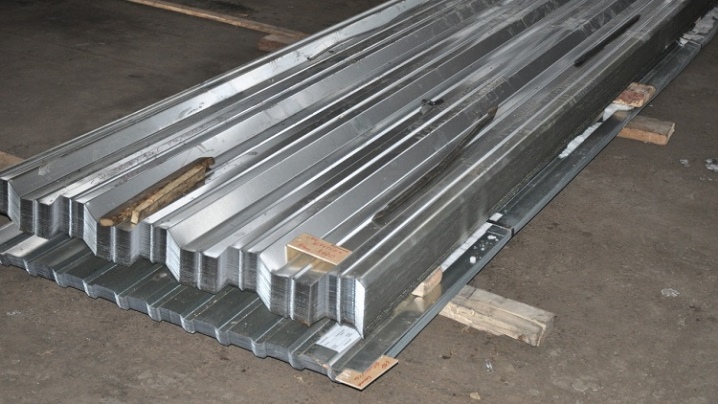

After rolling, the final stage of processing follows. The metal is cut by hydraulic shears in accordance with the specified parameters, then the product enters the receiving device, where its characteristics are automatically evaluated. Profiled sheets are made of stainless or ordinary steel - in this case, the surface is covered with a layer of zinc to avoid rust. Lighter products, usually aluminum - this material is used to lighten the weight of the structure.

For production, the GOST regulations are used, which dictate the permissible parameters of the product. They may differ depending on the original composition of the steel. There are also separate standards for protective coatings.

Properties and characteristics

Performance is directly dependent on the type of profile, so it makes sense to consider the features of the most common types in order to choose an option for a specific task.

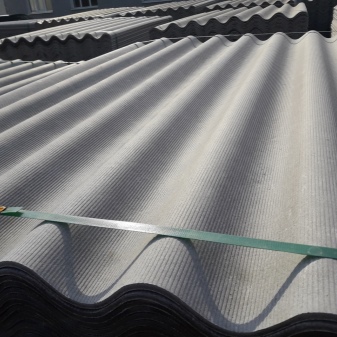

C8

Such sheets have a wavy surface and not too high strength. Most often, they are used to install fences, cladding, but sometimes they can also be used as roofing, if the roof has a large angle of inclination, and snow will not accumulate there. They have the following characteristics:

- thickness - from 0.5 to 0.7 mm;

- length - up to 12 meters;

- profile height - 8 mm.

C21

Sheets with a trapezoidal profile. Protected with a non-corrosive polymer coating. Suitable for roofs with a lathing pitch of no more than 80 cm, for cladding the walls of garages and other structures, for arranging a fence on the territory. Product parameters:

- thickness - 0.4-0.8 mm;

- length - up to 12 meters;

- profile height - 21 mm.

HC35

Durable products have a ribbed surface and a protective polymer coating. Well suited for installation on roofs with battens up to 1.5 meters. The flooring is airtight and reliable. You can also use the sheets as partitions and sandwich panels. Properties of the profiled sheet of this category:

- thickness - from 0.5 to 0.9 mm;

- length can be up to 12 meters;

- profile height - 35 mm with a trapezoid step of 200 mm.

H57

The profile of such sheets has the shape of a trapezoid. Feature - the presence of gutters. This allows the use of a thicker layer of insulating material during installation, which increases the reliability of the structure. Sheets are used in roofing works, for laying fixed formwork, installing shield barriers. Product features:

- thickness - 0.6-0.9 mm;

- length - up to 14 meters;

- profile height - 57 mm.

H114-600

Decking of this category is characterized by increased strength. This is facilitated by the presence of an additional stiffener.The weight of these sheets is more than that of others, it can reach 15.3 kg per m2. Products are used for the installation of structures subject to significant stress. Sheet parameters:

- thickness - from 0.8 to 1 mm;

- length - up to 13 meters;

- profile height - 114 mm.

Description of species

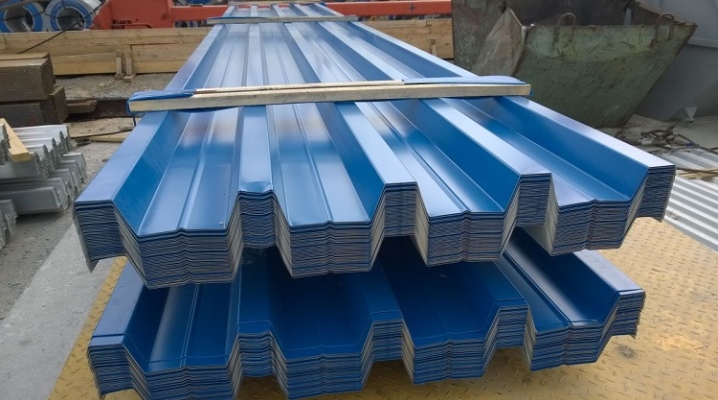

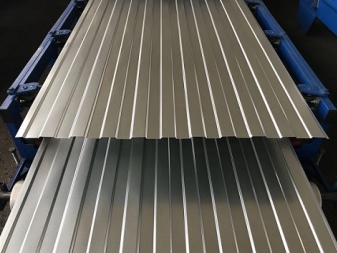

Manufacturers produce many types of profiled sheets for the construction of practical or decorative structures. On sale you can find options with different types of profiles - curly, arched, sea wave, trapezoid. Smooth and flat rolled metal without corrugation does not belong to the profiled sheet. You can find perforated products - the presence of holes facilitates installation. According to the type of coating, the profiled sheet is painted or galvanized. The most common classification of the profiled sheet is by scope. There are three types of products.

Carriers

Such sheets are used for the installation of structures subject to severe stress. These can be roofs on which a lot of snow accumulates, load-bearing walls or partitions, floors. The products have a long service life - from 40 to 60 years. Sheets can be recognized by their high profile and additional grooves required for strength. This category includes brands: H57, H114.

Wall

Usually they have a rectangular or trapezoidal profile. They are used not only for wall cladding, but also for the construction of fences, including decorative ones. Sheets of this type are thinner, so they are easy to process - cut, bend, drill holes. C8 and C21 brands are in demand.

Roofing

These products have sufficient rigidity and strength to withstand loads, but at the same time are lightweight so as not to weigh the roof down. The sheets are distinguished by an attractive design and a variety of colors. They are also used to install fences. Examples of brands: НС44, НС35.

Geometric data and volume

The length of the sheets can be up to 14 meters in some varieties, but more often it is limited to 12 meters. If necessary, the products can be cut, since such large specimens are not always needed. For example, for the installation of fences, sheets of 2 meters are often ordered, for wall cladding - 3 meters, and a length of 6 meters is also in demand. When buying, pay attention to the width. It is indicated in two dimensions - general and working. The first is the initial width of the sheet, the second is the one that turned out after the formation of the corrugation. Calculations for construction take into account the latter.

The thickness of products can reach from 0.4 mm to 1.2 mm. This is quite enough to create a durable coating, since the stiffeners reinforce the material, allowing it to withstand significant loads. The weight of the sheet depends on its dimensions and thickness. It is also influenced by the distance between the corrugations and the structure of the coating.

Usually indicate the weight per square meter, but knowing the parameters of the product, it is easy to calculate the area and understand how much the whole sheet weighs.

Colors and design

RAL and RR palettes are used for painting rolled metal products. They contain a large number of shades, for example: red, yellow, pink, green, blue, purple and others. You can also order the original painting for a timber or other texture. Even after a long time, the coating does not fade under the influence of sunlight and remains as bright.

Sheet marking

Products have an alphanumeric code that contains the main characteristics. It is not difficult to understand the notation. The first is the letter, and there are three possible options:

- C - wall sheet;

- H - carrying;

- NS are versatile products that can be used for cladding and roofing works.

This is followed by a number indicating the height of the profile. It can be written with a hyphen or right next to it, for example: НС-44, НС-21, СС10, С8, Н57.

After that, you can see three more numbers:

- sheet thickness;

- total width of the product;

- length.

The complete marking usually looks like this: C18-0.7-750-6000. You can understand that this is a wall sheet with a profile of 18 mm, its thickness is 0.7 mm, and its total width is 0.75 meters. The length of this product is 6 meters.

Popular manufacturers

When buying, it is better to choose products from trusted companies that have won a good reputation in the market. As a rule, large factories use modern equipment, which minimizes the likelihood of rejects and allows them to produce products with different parameters. There are many manufacturers who can offer quality decking.

- "Neva Steel". Located in St. Petersburg, it has existed for over 15 years. It produces finishing and roofing materials, as well as insulation, drainage systems, window structures and other goods for construction and repair.

- SevZapComposite. Located in Nikolskoye. It specializes in fiberglass and composite products, including the supply of profiled sheets for roofs and walls.

- Far East professional flooring plant. Located in Vladivostok, it produces various types of rolled metal products.

- Profmetal. The manufacturer from Stupino offers everything you need to equip the facade and roof.

- Ural Roofing Materials Plant. One of the oldest companies, which has been operating for over 25 years, is located in Yekaterinburg. Supports wholesale roofing materials.

Nuances of choice

It is important to choose the material that meets the tasks. Then the coating will not cause problems and will last a long time. In addition, there are other points to consider.

- It is better to buy the product from one supplier. It will be more profitable to immediately calculate the required amount of material and order a batch. This eliminates the need for a long search for a sheet similar in tone if the products suddenly run out.

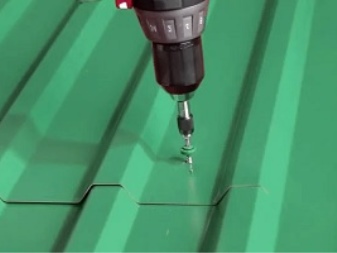

- Fasteners and accessories should be ordered together with the cover. This will ensure that the parts and the sheet are the same shade.

- Examine the packaging carefully. It should be intact, no damage. Also, the products themselves should not have defects - scratches, dents and other traces.

If you are planning roofing work, it is best to order long sheets. With short ones, the material consumption will increase due to overlapping laying, in addition, a large number of joints look unaesthetic.

Applications

The professional sheet is used in industrial and private construction. Thinner sheets are used for interior wall or ceiling decoration in workrooms. Partitions are made of them in large trade pavilions and hangars, used for the installation of kiosks. Sheet material of medium thickness is used for cladding the facade of a house or bath. You can also make a visor over the gate or a canopy over the porch from it, lay it on the roof of the gazebo. The most durable sheets with a large profile height are used for the installation of load-bearing floors, roofs with a wide lathing pitch, they are used for formwork when pouring the foundation.

Profiled sheet is often used to install fences. From it you can assemble a fence of any height, mount a large gate for the entry of vehicles or make a decorative structure for a front garden. It is not recommended to use corrugated board where there is a possibility of constant exposure to an aggressive environment. This can lead to corrosion. Also, the material is not suitable for roofs without lathing - with such a roof structure, condensation will accumulate under the sheets.

Operation and care

Although working with a professional sheet is not too difficult, there are certain nuances that you should know so as not to spoil the material. It is often necessary to cut products, but not all tools are suitable for this. Can be used:

- an electric saw with a special disc for a profiled sheet;

- a hand hacksaw for metal - if the amount of work is small;

- shears for corrugated board - electric and mechanical, suitable for thin sheets.

Gas cutting devices are not recommended - metal deteriorates from heating.Also, do not use a grinder, since the abrasive coated disc creates edge damage, which can subsequently lead to corrosion.

An equally important point is drilling holes. They are usually required to install fasteners. For this purpose, it is better to use special tools - a hole punch or punching pliers. If you need to put self-tapping screws, then a drill is also suitable, but it is important to monitor the speed of revolutions and do not forget to remove the shavings.

It happens that you need to bend the sheet along the corner, make a U-shaped bar or arch out of it. This can be done using a special bending machine - there are not only industrial, but also manual models that are suitable for private use. Some craftsmen can bend the sheet across at home with a hammer, but with this method, there is a high probability of getting an uneven line.

The corrugated board should be laid in a certain way so that the coating is reliable:

- laying starts from the bottom corner of one of the roof ends;

- wind strips must be installed after attaching the end row;

- if the sheets lie vertically, then the overlap should be at least 20 cm.

You can correctly lay the corrugated board with your own hands, if you follow a step-by-step work plan and follow safety precautions. As for leaving, there are usually no difficulties here. The roof is washed by rain, and snow disappears without any problems in the spring. Walls sheathed with sheet can be washed with a hose or use a soapy solution. If scratches appear, it is recommended that you purchase a paint of a suitable color in order to eliminate the defects.

The corrugated board is unpretentious, the coating of this material can last a lot of time, provided that the technology of installation and processing is observed.

The comment was sent successfully.