Installation of a profiled sheet

Everyone who buys and uses such material needs to know how to correctly lay a professional sheet - even if the work will be performed by hired builders, it is important to control them. The installation of the profiled sheet has two particular directions: fastening to metal purlins and to concrete. Having dealt with these topics, it will be easier to understand how to fix the corrugated board on the roof and screw it on the fence, on the wall.

Basic fixing rules

Competent installation of the profiled sheet largely determines how long it will last, and how reliable the protection of the base will be. In turn, installation errors immediately have negative consequences. For fastening, only specialized hardware is used, which ensures the greatest stability of the sheets. Violation of the integrity of the surface and decorative layers on it is unacceptable. Therefore, "traumatic" installation methods and tools cannot be used during work.

It must be remembered that the tear-off load of the wind action cannot be underestimated. Even without the announcement of a storm warning, it sometimes amounts to 400-500 kg per 1 sq. m. Therefore, the fixing of the roof must be mechanically reliable and carried out at strictly designated intervals.

This distance is calculated in advance to ensure that errors and distortion are excluded. Of course, the mounting force is carefully monitored.

Choice of fasteners

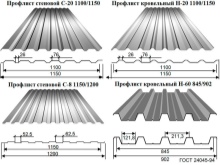

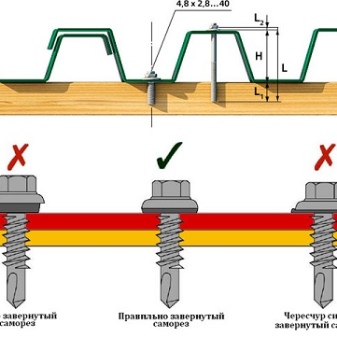

In practice, in everyday life, the corrugated board is fixed mainly with self-tapping screws. Their main types are distinguished by the material of the downstream support. Structures for fixing in wood are created taking into account its relative looseness (in comparison with metal). Therefore, the thread pitch has to be increased. This allows the threaded edges to grip large pieces of wood and hold as firmly as possible. But wood screws are also divided into two types. In one case, the tip is simply sharp, in the other, a medium-sized drill is used. Fasteners for metal are equipped with more frequent threads. It will not work to screw it into the tree, and if it succeeds, then the holding capacity will be too small.

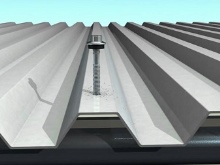

The tip always has a special drill; this is the only way to pierce both the main sheet and the base to which it is attached. Do not think that you can take a self-tapping screw for wood with a drill and screw it into steel. A much larger and more powerful drilling part is needed here. Moreover, some models are equipped with an even more powerful piercing unit; they can handle extra thick metal. It is necessary to understand that fasteners for the profiled sheet are also divided depending on where they will be used. So, on the roofs and facades of buildings, EPDM is required; for the fence, you can use hardware with press washers, which do not provide such a high sealing - yes, it is not really needed there.

Responsible serious manufacturers always mark their hardware with branded brands... As for the thickness of the zinc layer, it is impossible to establish it without examination in the laboratory - but conscientious suppliers write this indicator as well. It is useful to inspect the gasket: normally its thickness is at least 0.2 cm, and the material is springy when compressed. If you remove the gasket and clamp it in the pliers, then the paint should not crack. The length of the self-tapping screw is estimated quite simply: add 0.3 cm to the sum of the thicknesses of all parts to be connected - not forgetting at all about the gasket. It is useful to use hardware with a hexagonal cylinder head.They are the most convenient; they can be simply wrapped with an electric tool.

Often the question arises about fastening the corrugated board with rivets. The appearance of such a connection is quite pleasant. Its reliability is also beyond doubt. Quite often, the M8 V-shaped mount is used, which suspends mounting systems and parts to the wave of the profiled sheet. You need to fix such an element with a hairpin. Corrosion resistance is provided by galvanizing or by applying a mixture of zinc and nickel.

In some cases, fasteners with an M10 nut are used. It is also quite convenient and comfortable, does not cause any noticeable complaints.

Installation instructions

On the roof

When fixing the corrugated board as a roof covering, special roofing units are created. We are talking about:

- cornice;

- endova;

- skate;

- abutments from above and from the side;

- ridge.

Each of these parts has its own specific requirements. So, on the cornice, the profiled sheet is attached only over the equipped frame. It is created from a wooden lath, pressed with self-tapping screws using plastic dowels. The distance between the fasteners is normally 400-600 mm. Holes with a given pitch are drilled in advance, so that later the sheets are pressed in the designated places without problems.

The rigidity of the structure is achieved if the bars are connected with crossbars from a bar. When arranging the valley sheets, you need to start into it. Fastening is carried out in all wave lines. It is imperative to deviate from the center line to exclude errors. The gutter must be mounted strictly from bottom to top, and not along any other path. Attention: it is unacceptable to fasten the corrugated board to the roof using simple nails. This will lead to the penetration of moisture inside and to rusting of the metal or rotting of the wood. Professional safety fasteners are inexpensive and can be used by anyone, so there is no reason to refuse.

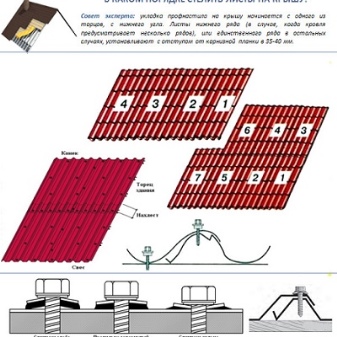

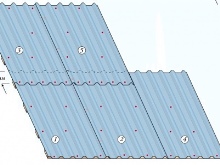

You should not take only long self-tapping screws - short ones should also be in the arsenal of roofers... Of course, the technology allows you to act in an arbitrary way, but shortened hardware can be wrapped easier and faster. The vertical laying technique is good for profiled sheets with drainage grooves. They start working on the first sheet of the first row. Then comes the initial sheet of the second row. When 4 sheets are temporarily fixed according to such a scheme, the assembly is trimmed and fixed completely. Then they are taken for the next four.

The three-sheet option is optimal if you need to mount sheets without a drain... Getting started - laying a couple of first sheets. Then a sheet of a higher row is installed. When the assembly is aligned with the cornice, it is securely fixed together. The overlap of the profiled sheet is determined by the angle of inclination of the roof. So, with a slope below 15 degrees, lay the sheets correctly - with a grip of at least 20 cm. It is highly desirable that at the same time they still go over each other in at least two waves. If the angle is from 16 to 30 degrees inclusive, you should put the corrugated board with the overlap of sheets of 15-20 cm. They are guided by the width of the waves. But with a steeper roof, the minimum overlap is already only 10 cm.

The overlaps performed horizontally should be at least 20 cm each. Each such area is supposed to be sealed. This problem is solved using roofing bitumen mastics or silicone-based sealants. Screw on 1 sq. m. profiled sheet is possible for 7-9 self-tapping screws, taking into account the arising loads. It is better to calculate the need with a margin in order to leave some reserve for marriage and unforeseen events. It is worth pointing out the typical mistakes when arranging a roof from a profiled sheet.... If too much hardware is used with a too large drill, then the tightness will be broken. And there is no need to talk about normal bearing capacity either. A very thin drill means either the fastener is broken or the thread is biting.

It is necessary to lay the sheets by pulling the self-tapping screw moderately hard so that it does not allow moisture to pass through and does not deform the gasket.

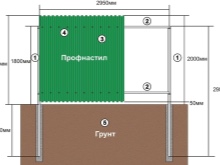

On the fence

Do not think that this kind of work is very easy. Her responsibility is no less than when arranging a roof. The optimal mounting method is the use of self-tapping screws. Rivets also work well. Important: fasteners should be made of steel, not aluminum or other relatively soft metals.

At least 5 self-tapping screws must be installed per 1 m2. It is advisable to screw them into the grooves of the waves. This guarantees a firm touch and inhibits the formation of rust. It is undesirable to mount the corrugated board by welding. A small exception is only its attachment to the wicket and gate.

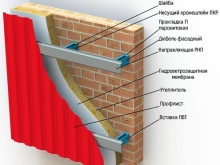

On the wall

Covering the walls with a profiled sheet is not too difficult. But you need to choose a material of increased strength. A sheet with a picture is more expensive than usual - however, its aesthetic effect is simply incomparable. It should be borne in mind that only sheets with a nondescript reverse side should be placed on the wall. The fact is that its graceful decoration costs money, but you won't be able to see it. It is not necessary to align the walls, because small defects are also invisible. However, it is necessary to remove all cracks, fungal lesions in advance. Anything that interferes with the finish is also removed from the walls.

Heavily crumbled masonry is partially knocked out and normal bricks are laid. The frame should be made as straight and straight as possible; it is necessary to fix it not by eye, but by level. When the marking is over, holes are drilled for all fasteners. Dowels and brackets are driven there. A good help is the use of paronite gaskets. When arranging a brick wall, the dowel holes cannot coincide with the seams of the masonry.

The guides are covered with insulation plates, mainly mineral wool; the insulating layer should be laid out in a continuous way.

There are quite a few other subtleties that should also be considered.... The fastening of the profiled sheet to metal girders can be done with self-tapping screws and rivets. The use of self-tapping screws is much easier, and even amateurs willingly use them. The rivet is reliable enough. However, you cannot disconnect it without losing quality. It is recommended to cover the joints and ends of the corrugated board on the facade of the fence with a steel bar of the same color as the fence. In this case, the hardware is placed in increments of up to 30 cm. For roofing installation, you can use special fasteners with a nut. Its fastening affects the installation height of the structure. It is worth noting that fastening to beams has its own characteristics.

If they reach a large thickness, installation is still possible. But it turns out to be very time consuming. The girders themselves or the timber are mounted in increments of 30 to 100 cm. An unbreakable crate is arranged under products with a wave of less than 2 cm. This rule applies when fixing to both wood and metal. Sometimes you have to figure out how to fix a profiled sheet to a concrete slab on the roof. It often seems that the simplest option is to attach it to concrete using special self-tapping screws. The problem is that the unevenness of the concrete does not allow the sheet material to be firmly and confidently attracted. Mounting on cement is not very reliable, since it does not allow for high-quality ventilation. Therefore, the lathing equipment has been and remains the most high-quality solution.

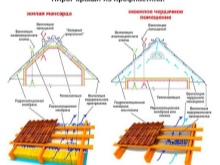

It is definitely better than even the best modern adhesives. The advantage is especially great when there is a significant load from wind and snow. It is most correct to fix the profiled sheet not on a wooden, but on a metal frame. The roofing cake can be arranged according to the classic scheme. It almost does not depend on the steepness of the roof. Ventilated facades can also be equipped on the basis of corrugated board. For them, take material with insulation or perforation. The insulated version is good because it reduces noise in the rooms. It also improves internal ventilation. From the profiled sheet to the base, a gap of at least 3 cm thick must be maintained - this is quite enough for normal air circulation and the prevention of excessive moisture deposition.

Start with markup. The step of fixing the brackets over 80 cm is unacceptable.Near the openings for windows and doors, this distance is reduced by 20 cm, it is also worth remembering about 20 cm indents from the corner. Only when the marking is over, you can confidently calculate the need for profiled sheet and fasteners for facing. You can even drill channels for brackets and anchors with a simple drill. The depth of entry is at least 8, maximum 10 cm. The mounting brackets are installed with a polyurethane gasket. 1 bracket requires 2 anchors. Rolled insulation, unlike slab insulation, is unacceptable. The windproof membrane is necessarily fire retardant. It is placed with an overlap of 10 to 20 cm. In order for the lathing to be correct, a building level is required.

The higher the required stiffness, the more important it is to reduce the distance between fasteners. It is very important in any case to determine the exact dimensions of the sheets in advance.

In the next video, you will find the installation of a roof made of corrugated board.

The comment was sent successfully.