Vibrating suspensions for drywall: features and characteristics

Vibration suspension is an important element of soundproofing structures. It perfectly dampens vibrations and significantly reduces the transmission of structure-borne noise to the frame of the noise protection structures.

Specifications

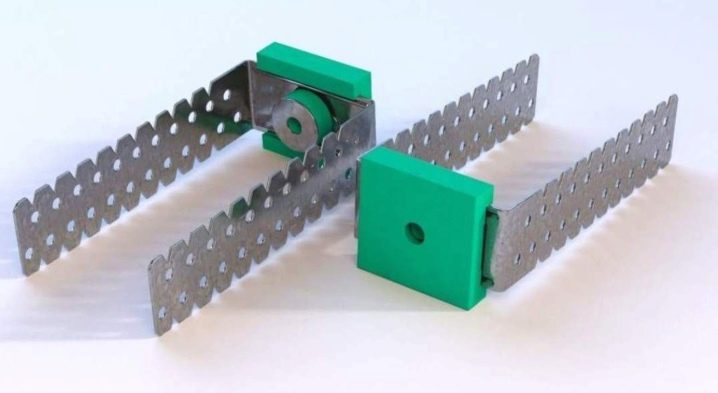

A vibration suspension is a U-shaped metal profile that has an insert made of an elastic material on its upper crossbar, which is often used as rubber, rubber or polyurethane. These soft washers absorb and dampen the acoustic wave. This happens due to the fact that the force of sound waves is spent on compression of the gasket and rotation of the hinge element, without reaching the plane of the protective structure. The thicker the polymer absorber, the greater the vibration amplitude it can damp. The vibration suspension is fastened with an anchor to the wall or ceiling, and the counterpart is attached to the profile using self-tapping screws.

Advantages

High customer demand and great popularity of vibro suspension due to the following product advantages:

- obstacle to the penetration of low-frequency noise due to high vibroacoustic properties;

- simplicity of construction and installation;

- versatility (most products can be used for installation of both ceiling and wall structures);

- moisture resistance, anti-corrosion properties and long service life.

Views

In the modern market of building and finishing materials, vibro suspensions are presented in a wide range. Products are classified according to the place of use, type of fastening, size and material of sound-absorbing washers.

According to the type of mounts, the box-type vibro-suspension is considered the best. It absorbs sound waves as much as possible and prevents them from penetrating the surface of the plasterboard wall or stream. The disadvantages of this type are the high cost and the need for accurate placement of the studs before installing the profile.

In terms of size, vibro suspensions for gypsum board are standard, designed for fixing on a profile, having a width of 6 cm, and economy class, combined with a narrow profile (4.7 cm wide). According to the scope of application, the products are divided into wall, ceiling and universal types. According to the material for the manufacture of noise-absorbing elements - for products made of rubber, rubber and polyurethane.

Vibration suspensions of all types are designed for loads up to 30 kg. The frame depth adjustment is carried out due to the presence of several holes located on the sides of the U-shaped structure.

How to do it yourself

You can also use home-made vibro suspensions. To create such elements yourself, you will need perforated plates and pieces of porous rubber. The number of suspensions is calculated individually and depends on the area of the wall or ceiling finish.

For example, in a room with an area of 15 square meters, 45-50 vibro-suspensions will be needed to mount a ceiling structure.

The suspension manufacturing technology is very simple. On the middle part of the perforated plate, it is necessary to fix rectangular rubber elements, after which the edges of the plates should be bent.

It is recommended to use multiple rubber layers for better performance. This will contribute to better damping of sound vibration, and increase the soundproofing properties of the plasterboard structure.

After the vibro suspensions are manufactured, it will be necessary to check their quality. To do this, fix the products on a wooden block, after which you will need to hit them on the floor. Immediately after the impact, it is worth observing the vibrations of the plates and determining their ability to damp vibration. The faster the vibrations damp, the higher the vibration isolation properties of the suspensions.

For more information on how to make a vibration suspension with your own hands, see the next video.

How to choose

When choosing vibro suspensions, it should be remembered that the most important quality of products is their strength. A significant load is placed on the suspension to hold drywall sheets, soundproofing material and a layer of putty. The simplest types of ceiling suspensions can withstand up to 12 kg of weight load, and budget options for wall products can easily hold 15 kg. Reinforced specimens are designed for 30 kg for the wall, and 20 kg for the ceiling.

The soundproofing properties of gypsum plasterboard structures largely depend on the suspension's ability to dampen vibrations and suppress noise. This indicator depends on the quality, thickness and area of the rubber or polyurethane washer. To ensure higher sound absorption, you should choose products with a larger area, thickness and elasticity of the material.

Installation features

Plasterboard installation on the ceiling consists of several stages.

- Measurement of the ceiling plane. It is carried out using a building level and consists in determining the lowest angle from which the distance necessary to place the lamp and soundproofing material is measured.

- Installation of guide profiles for the frame. Previously, a sealing tape is glued to the metal structures that will adjoin the floor. This eliminates the appearance of noise bridges, which, in turn, has a beneficial effect on the sound insulation properties of the structure.

- Marking to mark the places of installation of rack rails with jumpers. The location of the vibro-suspensions is also noted.

- Fastening vibro suspensions using dowels with further lowering of their edges.

- Installation of support rails frame and their fastening using vibro-suspensions.

- Laying soundproofing material on the frame and plasterboard sheathing.

The installation and operation of the vibro suspension is no different from the use of a conventional direct mount. The main task is the correct choice of fastening material, which depends entirely on the type of ceiling. It is necessary to connect vibrating suspensions with the frame profile using press washers or self-tapping screws.

When installing a soundproof structure, it should be understood that the full soundproofing effect cannot be achieved. Nevertheless, the use of sound-absorbing devices can significantly reduce the level of extraneous noise and make the stay in the room more comfortable.

The comment was sent successfully.