Subtleties of plasterboard installation

Having decided to start repairing a residential or office space, you need to think in advance what finishing materials you may need for this. Drywall is the first option for any finish that comes to everyone's mind. Lightweight, inexpensive, easy both in installation and in further operation - these are just some of the advantages of this material. Plasterboard is suitable for almost any interior, whether it is the simplest country house or a fashionable mansion. The thing is that it is the inner layer between the wall itself and the wallpaper, plaster, stucco and other finishes.

Peculiarities

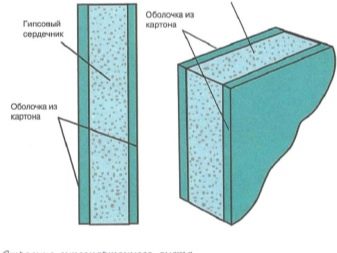

In principle, any sheet of this finishing material consists of two layers of very dense cardboard, which has little in common with the stationery multi-colored cardboard we are used to for school applications and drawing. The very name "gypsum board" suggests its constituent parts - a bonding mixture based on gypsum and highly durable industrial cardboard. Between the above two sheets, a layer of mineral or synthetic filler is laid, also with the addition of gypsum.

The secret to the success of drywall lies in its composite composition, that is, the multicomponent nature of the material. Here and fine particles, sometimes reinforced fiber, polymer or carbon base (also called a matrix). Any natural material has exactly the same structure, density, strength and other characteristics that nature has endowed it with. The composite material is created artificially by a person, due to which it is possible to lay exactly that composition of components and in such proportions as it is necessary to give it the necessary shape, texture, and so on in its basis or matrix.

Thanks to the possibility of self-modeling of material properties, it combines an internal porous medium to retain heat and prevent moisture from passing through, and a completely smooth outer surface. Such a matte layer of cardboard is convenient for covering both walls and ceilings in almost any room, because on top you can apply a variety of plaster, wallpaper, stucco and paint.

Views

First, you need to figure out what types of drywall are and how not to get confused when choosing exactly the name that you need. On the price tags in hardware stores, you can often see the abbreviation - GKL sheet. Do not be alarmed - this is a professional designation of the same drywall, but depending on its functional purpose, this or that letter may be assigned here.

Actually, the gypsum board itself or standard general-purpose drywall can be used exclusively for interior decoration of both residential and commercial premises. Such material is often taken for the manufacture of interior partitions in modern offices - the effect of individual rooms is visually created, although sound insulation in this case is minimal. It is also practiced to install partitions when the sheet does not reach the ceiling, since there is simply nothing to fix it from above.

Such a GKL sheet is not suitable for any climate., since it can withstand only a "normal" temperature by the standards of the middle latitudes of Russia - from about -20C to + 35C, then it will no longer be able to adequately perform its functions and will either swell from the heat or shrink from frost.For a house in a tropical jungle, it is also not recommended to install an ordinary gypsum board sheet, because it can withstand humidity no more than 70%. Since we are talking here mostly about the central part of Russia, then its residents have nothing to worry about when buying finishing materials. In the conditions of, for example, the Far North, before purchasing wall or ceiling drywall, it is worth consulting with a professional.

From the outside, drywall for standard use looks like a pale gray sheet, which is very convenient for further coating with paint or plaster. The gray color is faded, so it will not stand out even against the background of a thin layer of paint or plaster. This option is appropriate if, according to the author's intention, it is necessary to create a kind of surface with the effect of "unfinished" or an old abandoned factory in the loft style. Nowadays, this technique is often used when arranging art spaces or galleries.

In order not to be mistaken when choosing in the store, look for the dark blue GKL factory marking. Do not think that this type of drywall is of poor quality and can only be used in the construction of temporary structures such as cabins or public places. You just should not decorate them with external walls or rooms with extreme temperature changes, such as a sauna. In fact, you can even decorate a children's room with an ordinary GCR sheet without fear for the health and safety of your child.

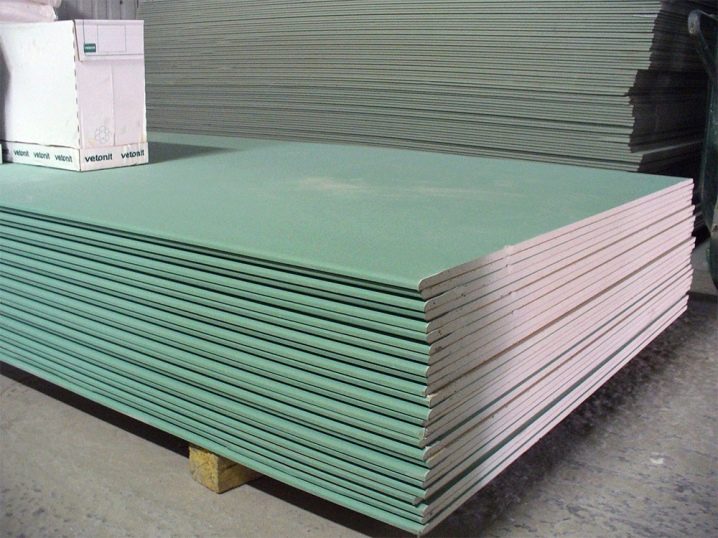

If you see a sheet of gypsum plasterboard on the shelf of a store, then it is moisture resistant drywall. The temperature in the room when finishing with this kind of material, as well as in the situation with the previous view, should not exceed standard norms. But the humidity is allowed higher than 70%. However, this does not mean that external walls or a shower stall can be clad with such material, because the essence of cardboard is unchanged - with prolonged exposure to water, it gets soaked.

An important advantage of the moisture-resistant function is, as it were, antifungal components sealed inside the sheet based on silicon or its oxides - crystal, quartz, silica, capable of absorbing the entire bactericidal environment. And the cardboard itself differs from the previous GCR version - binders with the effect of impregnated additives are sewn here, that is, impregnation with protective antiseptics.

The factory markings for GKLV sheets are of the same bright blue color as that of ordinary drywall, but for distinguishing the surface itself is no longer gray, but pale green. For the price, such a finish will already be several times more expensive, so you need to think about whether you really need to add the cherished moisture-resistant function.

As mentioned above, you can easily lay ordinary drywall in the children's room. If the floors and walls are often washed here, or the child is busy with creativity, coupled with the ability to spill water from the paint on the floor, then the GKLV sheet may also come in handy. It is also useful when the microclimate in the house itself is not very good, if there is a tendency to the formation of molds in the building.

GKLO is the new abbreviation for drywall with a fire retardant function. This name does not mean that such sheets can be used to decorate a bathhouse and similar premises. Just a short contact with an open fire and a short period of exposure to an elevated temperature is all that such a material is capable of. However, the so-called anti-fire function can sometimes save human life, for example, in case of fire. If ordinary drywall starts burning almost immediately, then in a room sheathed with GKLO sheets, a person will have 5-7 minutes in reserve to get out of the fire hazardous area.

Resistance to high temperatures is achieved due to the inclusion of fibers with reinforcement elements in the middle part of the sheet interspersed with cardboard. The outer layer of such drywall is impregnated with an anti-flammable or fire retardant liquid.

In appearance, drywall with a fire-resistant function does not differ much from the simple version of the material - it is the same gray. But the factory marking of the red "fiery" shade will immediately tell you for what purposes the finishing sheet is used. In terms of cost, it is several times superior to even moisture-resistant drywall, but this is the downside of including reinforcing fibers, which are expensive in production, in its composition. In homes where fires often occur due to gas leaks or old electrical wiring failing, this option may be the most suitable, despite the high cost.

Universal drywall for all occasions - both with moisture-resistant and fire-resistant functions, is designated as GKLVO. Such a finishing material can be found not in any hardware store, since due to the high price, it is almost never used in the decoration of residential and office premises. Combining both protective reinforcing fibers and water-repellent inserts, this sheet weighs many times more - not every wall can withstand.

Often, internal factory and industrial premises are trimmed with such drywall, where the risk of both fire and flooding is quite high. In private houses, where, for example, carpentry or pottery mini-workshops are equipped in outbuildings, GKLVO sheets will also come in handy.

In order to still find this type of drywall in the store, the developers came up with an interesting marker - they combined the color signs of both moisture-repellent and fire-resistant sheets. So, its surface is painted in a pale green color, as befits a cardboard with a waterproof marker. The lettering, on the other hand, is bright red, like the fire-resistant version. In any case, if you get confused, feel free to ask the seller for advice. He will quickly find the right option, because the choice of universal drywall with a full functional spectrum is not so great even in stores in the capital.

Also, drywall is divided into the following categories according to the place of installation.

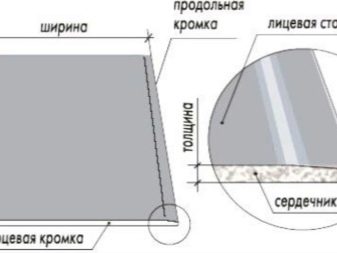

- Wall-mounted drywall - the most demanded option. In principle, if properly cut, it can be used for sheathing almost any more or less straight surface. Such a sheet is also perfect when installing partitions, both in offices and inside a small living room. Its thickness may be different depending on the set of additional functions such as fire resistance, but the average gypsum board sheet has a thickness of 10 to 13 millimeters.

- Ceiling plasterboard does not differ much from the wall, especially the composition of the cardboard or texture. The main feature is a lightweight design option in terms of filling with various materials and inclusions to increase strength and other indicators, since a heavy sheet of the ceiling simply cannot withstand. The ceiling version should be thin so that it can be easily cut even after fastening for the subsequent insertion of lighting fixtures. The average thickness of the ceiling sheet is 8-10 millimeters.

- Not as common, but no less popular than the previous two names arched drywall... The name speaks for itself - this type of finishing material must bend in different directions in order to lay it twisted in the manner of an arch, niche and other curves, or just in a non-standard room.

The sheet, which can take on various forms, most often contains reinforcing fibers., due to which you can bend it and make it freeze in this position. In fact, almost any arched drywall is fire resistant, so its price is noticeably higher than the usual ceiling or wall. As practice shows, only small areas in the room need a similar type of decoration, therefore, arched drywall is purchased in addition to the usual one in small sheets, 1-2 meters in length.Naturally, in order to bend, the material must be not very thick - no more than 6-7 millimeters.

The most popular when ordering in stores is an ordinary gypsum board sheet with parameters 1.2 x 2.5 meters. Its weight is about 30 kg. This information must be taken into account when going for drywall - it is worth calling a partner and renting a freight vehicle or ordering store delivery.

Instruments

Installation of drywall in residential or commercial environments does not require any complex professional tools. It is enough that every home “jack of all trades” has in a suitcase on the mezzanine. This is the indisputable advantage of drywall - ease of installation and a minimum of fixtures for it.

The following tools are required.

- Saw or hacksaw. Suitable for both cutting wood and synthetic polymer materials. You need such a saw when dividing solid gypsum boards into separate pieces of the desired size and shape. In addition to the usual saw, it is better to stock up on its disk version, since it will be more convenient for it to make long and straight cuts, separating parts of the drywall from each other.

- Electric jigsaw and drill. The first tool is needed to cut out parts of complex shapes, especially if these are not sheets of soft drywall, but parts of a metal frame. A drill, respectively, will be needed to fasten the sheets to the frame and adhere them to each other. If possible, you can buy a special drill attachment for mixing dry mixtures, since all this will be needed for frameless installation on glue.

- Screwdriver has already become a familiar tool in any apartment. It is needed to install fasteners when fixing plasterboard parts at the time of frame assembly, most often from metal profiles. In principle, the same manipulations can be carried out with a drill and a screwdriver, but the screwdriver acts softer, so the chances of breaking a rather fragile drywall structure are significantly reduced.

- Knife it is better to take a special construction one in order to cut the edges of the parts with high quality after cutting. However, if you do not want to spend extra money, use a well-sharpened ordinary kitchen knife with a thin long blade with skill.

- Roulette. Both automatic and laser are suitable. You can also use just ordinary metal, which is well suited for measuring the profile after marking and cutting into separate parts.

- Construction plumb line not required, but very convenient to use at the time of inspecting the position of the gypsum board in space during the installation of the walls.

- Paint brush, rollers of various shapes and a universal set of spatulas - everything you need for the correct application of the primer after installing drywall.

- Directly primer mix or acrylic putty, necessary for applying the top layer to the gypsum plasterboard in order to prepare for the subsequent coating with varnish, paint, wallpaper or decorative plaster.

- Plastic containers large capacity, where soil or glue will be kneaded. It is advisable to have a separate disposable container for each type of mixture, which you do not mind throwing away later.

- Emery cloth for mashing irregularities, so that each next layer lays down smoothly and without gaps, because in the future this can affect both the strength of the structure and the formation of mold in places of poor grouting.

- Insulation, laid directly between the wall and a sheet of drywall during the construction of partitions or wall decoration for the purpose of insulation and sound insulation. It can be either mineral, created specifically for interaction with drywall, or ordinary glass wool, which also keeps heat well.

- Rack and horizontal profiles, brackets, fasteners and self-tapping screws are absolutely irreplaceable things when installing a metal frame and stitching individual gypsum board sheets together.

How to calculate the expense?

Before starting repair work, it is necessary to thoroughly measure the area of the room to be finished so as not to buy extra sheets of drywall. The calculation of the area of the walls, like the ceiling, is done traditionally - the length of the surface is multiplied by the height. Window and door openings do not need finishing, so first you need to calculate their total area in the same way, and then subtract them from the area of the entire wall as a whole.

Drywall is most often sold in whole sheets - this should be taken into account when buying the so-called surplus "in reserve". They usually take no more than one fourth of the required area of the room, so that it does not turn out that a huge, expensive gypsum plasterboard sheet remains superfluous, which then simply has nowhere to put for storage. However, if the room for the repair is of a non-standard shape, there are curves or niches for which it will not be possible to accurately cut the desired shapes the first time, it is better to be able to redo the work with the help of spare drywall.

When calculating the amount of purchased material, it is usually taken as a basis that the width of almost any sheet is standard - 1200 millimeters. Only length, weight and thickness vary here. In length, the sheet is gaining from two to three meters in increments of half a meter. The thickness of the gypsum board sheet is chosen depending on the functional accessory - 6 mm is suitable for finishing arches, slopes and other non-standard elements where drywall needs to be bent. The thickness of 9.5 mm is ideal for ceiling slabs - it does not weigh down the entire structure, but it also protects from the noise of neighbors. For walls, they most often buy a sheet of 12 mm thick, which, together with a gasket made of insulation, retains heat and creates good sound insulation.

As mentioned above, some of the material can go to the trash can.if the sheets are cut poorly or the dimensions are incorrectly calculated. The self-tapping screw can also come off and ruin a piece of sheet, so take better 1-5 meters more than you need for a minimum overlap of the room. For example, horizontal profiles for mounting a frame with a standard section of 28X27 mm are mounted 4 pieces at each intersection of frame beams - two at the top and two at the bottom. Such profiles consist of a main body and whips, the total length of which is equal to the perimeter of the room, multiplied by two.

Another integral element in the frame installation of drywall is rack profiles with a section of 27X60 mm. They are fastened along the entire length of the wall with a distance of approx. 500-600 mm between the individual parts. In order to correctly calculate the required number of such components, you need to divide the length of the wall by 0.4 and multiply by the height of the room.

An average of 5 brackets are prepared for each rack-mount profile, but buy an extra 10-15 pieces just in case. Part of such a fastener can be lost during transportation and preparation for repair, and part can simply break during installation.

Self-tapping screws are the main consumable, so it is better to buy them thoroughly. For a room with an area of 20 sq. m, purchase them at least 400-500 pcs. Nowadays, even in regional stores, such a trifle is almost everywhere, so if necessary, you can always quickly buy them.

With the frameless installation method, a special construction adhesive is needed to fasten drywall to walls and ceilings. Its consumption is calculated based on 1 sq. m wall, and for each type of glue it is individual. Brief instructions for consumption are usually given on the packaging. Even if you plan to finish only a small section of the wall, stock up on a second bag of glue. It is not uncommon for craftsmen to mix up fast-setting glue incorrectly or do not have time to use it, and then the product has to be thrown away.

Room layout

Before starting the installation of drywall, it is necessary to mark on the plane of the wall or ceiling where which element will be located, as in a children's application.The boundaries of individual sheets and the joints between them can be outlined with a simple pencil. He also marks the contours of door and window openings at the level where the gypsum board will be attached.

For the correct installation of the frame, it is also better to first mark the boundaries.where each horizontal and vertical beam will stand. Such markings are straight lines running at the same distance from each other, most often with a step of 50-60 cm.

To carry out better markings of the room, you can use a device such as an electronic or laser tape measure. It automatically measures edge-to-edge distance by placing it against one end of the wall and aiming the beam at the other, helping to avoid errors in calculating the required material.

Frame

The most popular way to install drywall is to put gypsum boards on a pre-fabricated and installed frame. Its main advantage over the frameless method is the ability to perfectly join sheets even on uneven and inclined surfaces, hiding all the roughness. In addition, a rather large gap is formed between the frame and the drywall, where electrical wires, lighting fixtures and other equipment can be mounted in a hidden form, the inside of which should not be visible to the inhabitant of the house. In the same gap, a layer of internal insulation or soundproofing material is often laid.

The presence of a distance between the wall and the cladding can narrow an already small area. rooms in a small high-rise building. This problem for a country house or apartment with a sufficient area does not seem to be a problem at all. Yes, and it is easier to change or repair part of the drywall covering by removing it from the frame than trying to tear off a sheet attached to glue from the wall. If the neighbors are flooded and water flows through the gypsum plasterboard, then the only way to quickly restore a suitable appearance of housing is to have a repair based on the frame installation of sheets that quickly separate from the wall.

Frames are of two main types - metal and wood. Their assembly technology is identical - wooden bars or metal beams are fastened together in the manner of a mesh. The first material, of course, is more environmentally friendly, and cheaper at a price, but, nevertheless, not as popular as metal. The thing is that wood requires additional processing with fireproof, moisture resistant and antifungal impregnations. However, even with these precautions, such a frame can simply rot before the outer plasterboard sheathing.

If there is a desire to install hidden electrical wiring between wooden bars, then the wires will have to be hidden in an additional protective box, which ultimately will be quite costly for the budget. But the most uncomfortable situation can arise with a sharp temperature drop in the room, because the tree tends to expand in such situations. The wall swells in unfavorable conditions, and the drywall begins to lag behind the surface of the frame. Often, such a misunderstanding can be found in suburban huts, where the owners rarely come - the house stood in the cold in winter, then people arrived - they heated it up, and the process began.

All of the above disadvantages of wooden frames do not mean that in no case should they be installed. With proper assembly, processing with the necessary compositions, and most importantly, a successful choice of a drier wood species, an equally wear-resistant frame is obtained that can hold drywall for decades.

So, it's time to proceed directly to the installation of the frame. This process can be conditionally divided into several stages.

- Preparing the room itself for installation, that is, removing furniture, covering the floors with a protective film, cleaning the walls from previous layers in the form of wallpaper or plaster.Frame beams are a structure that occupies almost the entire free area of the room, therefore, having introduced them into the room, it will already be difficult to perform any manipulations other than installation in it.

- If electrical wiring and other communications in the form of wires are sewn into the wall under the frame, then they must be carried out, pulled into bundles, and possibly put into boxes before starting installation.

- According to the rules, first, the installation of both upper and lower metal beams or profiles, directed in the horizontal direction, is carried out. With the help of self-tapping screws, these profiles are installed immediately around the entire perimeter of the room. The first beam goes from wall to wall, and the next ones - joint to joint with neighboring ones. Screw the upper profile to the ceiling, and the lower one, respectively, to the floor.

The best way to ensure that both U-profiles are secured evenly is to pull on the construction cord like an impromptu ruler. Watch also the plumb line, which is mentally lowered from the longitudinal center line of the upper profile. Ideally, it should coincide with the same line of the lower beam - this means that everything is installed correctly, without deviations and curved lines.

- Now you can fix vertical profiles from above - either close to the wall also using self-tapping screws, or by separating them from the wall with additional brackets. It all depends on the degree of evenness of the wall - if it is practically straight, that is, the irregularities protrude within 5-10 mm, then we attach horizontal and vertical metal rods almost close to the base. When the wall is uneven or tilted, it is best to attach the beams vertically with brackets.

It is not necessary to screw these additional parts close to the ceiling or floor. - the brackets must rise at least 300-600 mm from the edge. They should not be sculpted close to each other either - observe the minimum step of 10 cm.

The last stage is the installation of rack profiles, which need to be adjusted in size to the distance from floor to ceiling, having previously measured and cut equal parts with a grinder. All beams are fastened together with special U-shaped holders with paws, which, in turn, are screwed into a single structure with self-tapping screws. The legs at the holders at one end hug the tie of the horizontal and vertical profiles, and at the other end they are attached to the wall. Excess and protruding parts of the holders after fastening can be cut off with special scissors.

Frameless structures

Having a small apartment, not everyone can afford to install a bulky frame for wall decoration with drywall, which eats up a lot of useful space for furniture. Low ceilings also do not imply frame installation, since screwing the chandelier at a level where it can be hit by your head is simply inappropriate. For such cases, frameless drywall installation is just suitable, when the sheet is attached directly to the wall or to a thin substrate.

There are several ways to directly attach the plasterboard structure to the walls and ceiling, depending on what kind of adhesive is inside - between the wall and the sheet.

The most popular way is, in fact, bonding sheets with construction glue. It is sold in the form of a dry mixture, which is bred immediately before installation. The glue hardens quickly enough, therefore, before diluting the composition, it is necessary to prepare all the necessary tools - a stirring stick or a special attachment for a drill, as well as a disposable container.

Depending on the degree of unevenness of the wall, the adhesive is applied using different technologies. For example, if the surface is practically smooth or there are small indentations up to 10 mm, then you can apply the glue as on a regular applique board. First, you need to smear it with a thin strip along the perimeter of the sheet, and then, pointwise in the center, make several circular applications.When the roughness of the wall is visible with the naked eye, that is, in a volume of about 20 mm, the glue is applied pointwise along the entire perimeter with a thick layer in the form of semicircles.

If the wall in the room has open potholes or destruction, then it is better to pre-seal them with inserts from cut pieces of the same drywall, and then mount the main sheet. When large irregularities are encountered more than once, but are distributed over the entire surface, then it is worth attaching whole strips under each other from a spare cutoff the size of an average pothole and a distance between the stripes of 20-30 cm as a substrate.

The second most popular method is finishing with polyurethane foam. This option is more suitable for wooden walls, as there is less chance of swelling of the wood when the two come into contact, especially if the foam has a low coefficient of expansion.

With any method of frameless installation of drywall, the algorithm of actions is as follows.

- Prepare the walls, that is, cleanse of previous layers of paint or plaster, soak with a special primer, preferably on a water-based emulsion.

- After carefully measuring the room, cut drywall sheets of the required size, number them. Just like the walls, the gypsum board sheet must be impregnated with a primer and allowed to dry.

- After 1-2 hours, apply foam or glue to both surfaces, carefully applying joint to joint to other parts. Having pressed the sheets against the wall, it is necessary to hold them in this state until the glue dries. It is better to carry out such an operation in at least four hands, or for reliability, in addition to glue, fasten the parts along the edges with self-tapping screws.

- After hardening, pieces of foam or glue protruding in the corners can be cut off with a special knife and the surface in the areas of joints and irregularities can be sanded.

Mounting

In order to sheathe the walls with drywall with your own hands, you will not need so many skills and tools - self-tapping screws, rack profiles and a screwdriver from the basic set. The pre-prepared sheets should be cut to the size of the room so that, ideally, the entire wall from floor to ceiling can be covered with one piece, without joints in the middle. It is better to work with a partner so that you can fully hold a sheet several meters long. During the facing of door and window openings, it is most convenient when one person presses a sheet of drywall to the desired hole, and the second draws the outlines of the window or door, in order to then cut everything along the line.

The simple process of installing gypsum board sheets occurs in several stages.

- When installing plasterboard sheathing, the first sheet is placed clearly in the corner of the room, pressing the edges against the opposite wall, floor and ceiling, respectively. If the first is the finishing of the wall with a window or door, then the desired sheet, as on spacers, is pressed against the corners of this space.

- Aligning the sheet with the frame details and pressing tightly against it, you first need to screw the surface to the vertical profile with self-tapping screws. At the same time, the screwdriver should be set to not the most powerful mode, so that the screw, when screwed in, does not damage a sufficiently thin drywall. It is better if the cap is not lower than 1 mm recessed into the surface of the sheet. The distance between the elements to be screwed in should be approximately 20 cm - this is the optimal gap for a standard sheet width of 120 cm.

- After making sure that the sheet has been tightly laid in the sinuses and it independently holds on to the vertical rack profiles, in the same way, you need to attach the drywall to the horizontal jumpers with self-tapping screws.

- The second and all subsequent sheets must be tightly pressed against the neighboring ones and oriented in the strict horizontal position of their arrangement, also on the basis of visual comparison with the already installed plates, and not only along the plumb line.

- Windows and doors should be sheathed according to the same algorithm as ordinary walls, but according to pre-adjusted and cut shapes.It is possible and even necessary to sew up door slopes at the last moment, since this is already considered a fine decorative finish.

- And now the GKL sheets are installed, but this does not mean that the repair is over. After all, you still need to finish all the irregularities and joints, as well as the places by screwing the self-tapping screws, with putty, preferably with the addition of a reinforced fiberglass mesh. This know-how will allow you to avoid diverging from tremors and other vibrations of the joints. The mesh will also help keep the wall from swelling from the inside with a sharp temperature drop. After applying the first layer of putty, for reliability, it is better to smooth it with an emery cloth and apply again after drying.

- If not only the external beauty of the walls is important, but also their insulation, then a special insulation material must be laid in the gaps of the frame before laying the drywall. Most often, mineral wool or glass wool is used - after all, these materials are good for sound insulation. In specialized premises such as recording studios or dance halls, for total sound insulation, special synthetic materials are purchased - pads, and they are fastened like a regular insulation.

- After applying the second layer of plaster, it is necessary to smooth the surface again with sandpaper, and then you can proceed to the external decor in the form of installations from tiles, mosaics, wallpaper, paintings and any other elements.

Finishing work

The final stage of the plasterboard installation is the final finish. But before gluing wallpaper or applying decorative plaster, it is necessary to prepare a gypsum board sheet.

To begin with, use an emery cloth several times as if on a smooth sheet surface., and with enhanced control at the joints of the plates, roughness, soldering of self-tapping screws or excess glue coming out to the surface. Next, you need to apply a layer of primer with moisture-repellent and antifungal functions and let this mixture dry and absorb for at least a day.

For gluing wallpaper, glue is applied and the joints of individual wallpaper sheets are pre-marked. If the outside is finishing with decorative plaster, then, as a rule, it already contains adhesives in its composition, so you do not need to add anything to it.

If you only want to paint drywall without applying additional finishing elements, it is better to apply this paint in several steps, letting each layer dry for at least 5-6 hours.

Tips & Tricks

It is not difficult to independently mount a wall or ceiling made of plasterboard, but in order not to overpay in vain and at the same time choose the right quality material for your home, there are a number of recommendations.

- For residential and constantly heated premises, an ordinary GKL sheet is suitable - its characteristics are enough to last long enough. The level of its environmental friendliness and low toxicity makes it possible to mount it even in a nursery.

- For rooms with high humidity and a tendency to the formation of fungus, such as a bathroom or kitchen, it is better to use moisture-resistant drywall, although it is more expensive than usual.

- If a private house has its own boiler room or boiler room, then in such a place it is better to work with fire-resistant drywall and not be afraid of temperature changes.

- Where you can spend a lot on a universal GKLVO sheet is for the attic. If it is a semi-open or weakly glazed room, then there will be temperature drops, high humidity, and fungus. Also, any installer will advise you to attach a good layer of mineral insulation here.

- When the area of the room allows at least a little, it is better to use the frame method of plasterboard finishing everywhere, since this is the only option in which the subsequent dismantling of the sheets will take place with the least damage.

Advantages and disadvantages

Gypsum cardboard as a finishing material has a number of undoubted advantages:

- Low price compared to natural facing materials.So, in hardware stores, a gypsum board sheet costs from several hundred rubles to several thousand, depending on its functional purpose.

- This material is easy to install, it does not require special training from the master and complex tools. It only takes 2 people to finish a 20-30 square meter room in one day.

- The smooth surface of drywall is suitable for further finishing with almost any decor, be it wallpaper, plaster or paint.

The downsides include the following:

- The ability of drywall to eat up space in small rooms due to the frame protruding from the wall.

- With frameless installation, in the event of flooding or other reasons due to which it is necessary to dismantle the sheets, they will have to be torn off by their roots without the possibility of restoration.

- Relative fragility of drywall when cutting and mounting on self-tapping screws. But when modeling individual parts, its ability to take different forms and bend can be attributed, rather, to the pluses.

Everyone chooses the finishing material for the renovation according to their tastes, abilities and wallet. However, drywall can be called a versatile option with the most benefits at a very modest cost.

For a few more tips for installing drywall, see the video below.

The comment was sent successfully.