Fire-resistant drywall: characteristics and scope

When choosing certain building materials for repair work, experts recommend relying on those that are fireproof and reliable. One of the best examples of such materials is considered to be fire-resistant drywall, which has the ability to withstand high temperatures. Many consumers have doubts about the qualities of drywall material at relatively high temperatures, but first you need to familiarize yourself with the main distinguishing features of fire-resistant drywall products and conventional drywall.

What it is?

Fireproof drywall is a special material that includes components such as cardboard and gypsum. This material is additionally processed with a special special substance (fire retardant).

Due to the properties of the materials, drywall can withstand up to 60 minutes of open firepreventing smoke from spreading and preventing further combustion. Fireproof gypsum board in its structure has crystallized water (1%), which, during combustion, slows down the further spread of fire for a long time.

A distinctive feature of fire-resistant drywall from its moisture-resistant version is the color of the material - in the first it can be red or pink.

Plasterboard materials are called fireproof, because the material is made by maximizing the compression of the elements, as a result of which air does not penetrate into the structure. The combustion process is impossible without free access of oxygen, and if there is no oxygen, then the fire will stop spreading.

The use of GKLO has a number of advantages:

- Fire-resistant drywall can be used in any room. The material is made from environmentally friendly products, therefore it is often used in children's rooms, educational institutions, hospitals.

- Moisture-resistant gypsum plasterboard has high fire resistance due to crystallized water in the composition.

- The composition of the material includes clay, which contributes to excellent sound insulation and thermal insulation.

- Unlike identical analogues of such material, drywall will last 5 years longer.

- Provides an accelerated surface leveling process.

- The building material is easily cut and bent to achieve the desired size and shape of the slab.

Despite all the advantages of non-combustible drywall, this material also has some negative sides:

- Weak indicator of strength. Any minor loads will lead to deformation of the building material. Installation of fasteners (nail, self-tapping screw, hanger) requires additional measures for strengthening.

- To paint drywall, you will need special coloring products and putties. To cover such surfaces with wallpaper in light shades (beige, white), it will take a lot of effort to cover the pink color of the drywall.

- The high price of products. The cost of a fireproof drywall product is twice the cost of a conventional drywall. However, family safety is probably more important for everyone than saving money.

GKLO reaction to fire

Heat-resistant drywall can withstand exposure to an open flame for a certain time, depending on the type of this material.When the time limit comes, the destruction of the drywall product occurs. The GKLO system has a core in the form of fiberglass (filaments from 4 mm to 3 cm long); additions to fire protection are inclusions of clay and crystallized water. It is thanks to these components that drywall can resist burning for a long time.

After the expiration of the time limit, the plasterboard shell begins to burn out, and the core begins to crack, but during this period of time, measures can be taken to prevent the spread of fire. Basically, these minutes are not enough for the fire services to get to the fire.

Types and designation

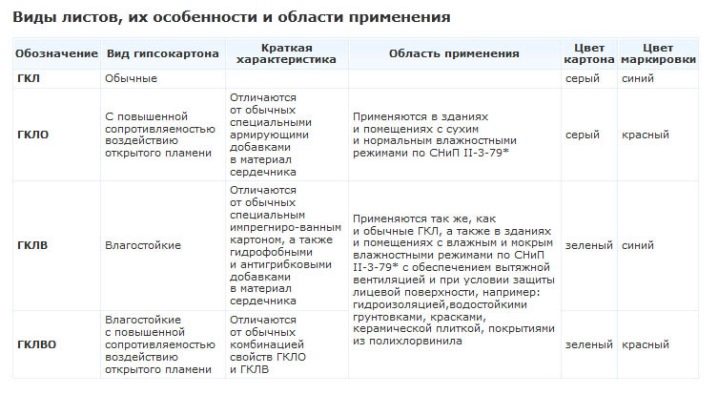

On the construction market, you can find several varieties of gypsum boards that have fire-fighting qualities.

- GKL - ordinary plasterboard sheets.

- GKLVO - moisture resistant fire resistant gypsum plasterboard sheets. They are used for finishing work in industrial premises where high humidity prevails and high fire safety requirements are set. The color of this material is green with red markings;

- GKLO - fire-resistant gypsum plasterboards with high resistance to open fire due to the reinforcing components included in the composition. GKLO is able to withstand up to 20 minutes of contact with open fire. The color of this material is gray (beige) with red markings.

Comparative table of varieties of fire-resistant plasterboard materials.

Plasterboard sheets differ in the edging model:

- PC - straight line;

- Of the Criminal Code - refined;

- PLC - semicircular from the front;

- PLUK - semicircular and refined;

- ZK - rounded shape.

Specifications

The fire-resistant model of the middle GKL sheet has approximately the following specifications:

- The standardized value is 2500x1200x12.5;

- Weight - 30 kg;

- Density - 850 kg / m3;

- Flammability discharge - G1 (fireproof);

- Flammability - B1 (fire resistant);

- Toxicity - T1 (harmless);

- Heat conductivity - 0.22 W / Mk;

- Thickness - 6.5, 9.5, 12.5, 14, 15, 16 mm;

- Width varies from 0.5 to 1.3 m;

- Length - up to 5 m.

How to choose the right one?

In order not to be mistaken with the choice of drywall product, it is strongly recommended that the product package contains a quality certificate, which must contain certain indicators of fire safety:

- D1 - smoke formation;

- B3 - flammability;

- G1 - flammability;

- T1 - the content of toxins.

You should also pay attention to the following features of drywall material:

- appearance - sheets should be perfectly flat and without mechanical damage (cracks, scratches, bends);

- product labeling - on the back of the product there must be a label describing the manufacturer, size, model, GOST;

- storage conditions - you must make sure that the storage was carried out correctly (at an air temperature of at least 10 degrees).

Scope of application

The use of fire resistant drywall is common for the following types of work:

- facing work in rooms with high and abnormal temperature conditions (swimming pool, boiler room, boiler room);

- children's rooms and hospitals;

- creation of partitions for walls in educational institutions;

- finishing works in rooms, the structure of which is made of wood;

- cladding of fireplaces and ventilation systems - heat-resistant plasterboard can be used not only as a means of protection, but also for decorating premises.

Manufacturers

Plasterboard manufacturers offer a wide range of drywall structures. The German manufacturer Knauf is very popular. 70% of consumers in Russia prefer this particular brand.

Knauf

Knauf has more than 10 of its own factories throughout Russia. Positive customer reviews are based on the fact that the material is made using high technology.The main parameters of Knauf fire-resistant gypsum board are a high fire resistance limit and a relatively small mass of material. Heat-resistant drywall resists open fire for 50-60 minutes.

Pros:

- accelerated installation process;

- additional GCR treatments are not required;

- installation work is done without dirt;

- the material allows the walls underneath to breathe;

- the thermal conductivity of drywall is higher than that of other similar building materials;

- the high strength of the product allows you to mount such special material even on surfaces that are exposed to external mechanical damage;

- affordable price of products.

Disadvantages:

- to create complex geometric shapes from Knauf drywall will require a lot of effort and additional tools;

- the price difference between Knauf products and similar materials is 15-20%.

10% of the population use plasterboard products from manufacturers of the Rigips, Lafarge, Giproc brands. Another 20% of buyers speak positively of domestic producers, namely, Magma and Volma companies.

Production of the company "Magma" - the winner in the category of value for money. Heat-resistant drywall has high parameters of class A. The fire resistance limit is about 45 minutes. Many manufacturers provide the opportunity to order non-standard size fire-resistant drywall.

Volma

Volma gypsum plasterboards have been produced by a Russian manufacturer for over 10 years. Refractory sheets are made using technology that meets all fire safety standards. The technical and operational qualities of the GKLO of this nonsense are not inferior to foreign counterparts, as a result of which the high demand of buyers looks quite justified.

Advantages:

- due to its durable and elastic construction, the GKLO allows to carry out finishing works of complex shapes (arches);

- in comparison with the prices for Knauf "Volma" products - 30% cheaper, which allows you to save on surface finishing;

- the quality of the thinned edge of the sheet allows you to cut the material evenly and without crumbling.

Disadvantages:

- has no marking lines, which complicates the process of aligning sheets during installation;

- the sheets are characterized by slight waviness.

Installation recommendations

- To enhance the effect of fire resistance, you can mount two layers of drywall or install GKLO on steel frames. When installing two layers of drywall, the laying step between the profiles must be reduced.

- Experts do not recommend installing fire-resistant material on a wooden frame, because wooden coatings burn very well. It is better to use metal profiles for installation.

- When installing heat-resistant plasterboard on top of electrical wiring, it is imperative to perform additional cable insulation.

- The installation of partitions is carried out in such a way that there are no gaps, otherwise the sound insulation will be insufficient.

- The amount of fire-resistant drywall purchased is calculated with a margin of 10%.

The use of fireproof gypsum plasterboard sheets really increases the fire safety of the living space. Also, GKLO can regulate the humidity in the room due to the fact that this material has the property of absorbing excess moisture. If the air in the room has become dry, then the opposite process occurs - the return of moisture into the air space. We can say that installing drywall helps to normalize the indoor climate.

In the next video, you will see the fire resistance test of drywall.

The comment was sent successfully.