Profile dimensions for drywall

In modern times, there are a lot of opportunities to make a room beautiful and comfortable with a minimum amount of costs. One of the options is to use drywall sheets, which will be discussed in more detail in this article.

Peculiarities

Profiles are a very important element in the creation of any interior. In order for the structure to withstand the plasterboard, the profile is made of steel or aluminum. Steel options are more popular, due to the fact that these are economy class models. Aluminum have better characteristics, but their price is not suitable for everyone.

There are two types of steel profiles - regular and with a protective layer. Regular profiles are not very strong, but they are cheaper. It is good to use such profiles for not very heavy structures, as well as in rooms in which there is no too strong humidity.

For rooms in which the humidity is higher, it is better to install galvanized or aluminum metal profiles.

Types of metal profiles

In any hardware store, you can find a large number of different profiles. In order to choose the right one, you need to understand how they differ from each other. There are the following types of structures:

Guide

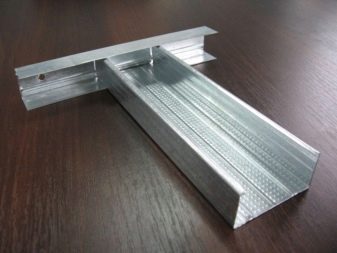

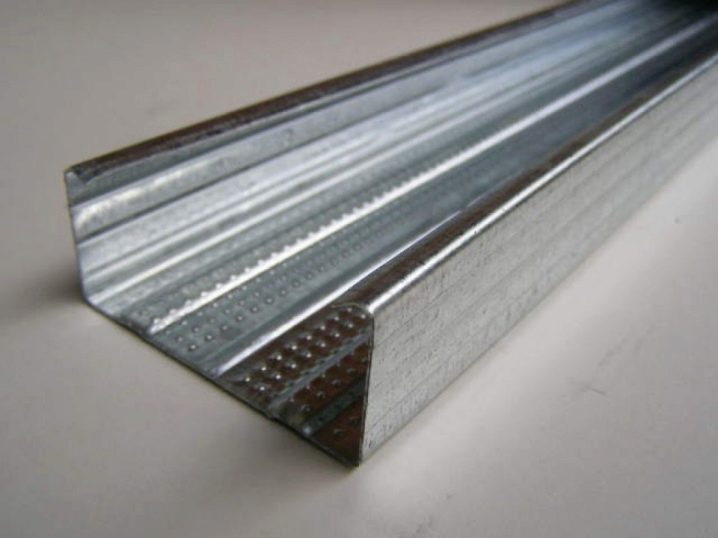

The abbreviated designation of this profile is PN (guide profile), it is also called starting. It has a U-shaped cross-section. The walls of this profile are smooth. Most often, this product is used to support various jumpers and racks, it is placed inside the structure, and the rest of the parts are put on it in the future. Sizes: 28-27.50-40.60-27.75-50,100-40 mm.

Rack

It is usually denoted by the abbreviation PS. This profile is inserted inside the guides, the rest of the parts are attached to these structures. The profile carries a large load, because of this, it must be more rigid. He also has a structure in the shape of the letter P, it has additional shelves to strengthen the structure. Dimensions: 50-50.65-50.75-50,100-50 millimeters.

It is necessary to pay attention to one important fact. If the walls in the building have a fairly flat surface, then the rack-type profile is best fixed directly to the wall surface.

If the walls are not very smooth and have a strong slope in a straight line, then the profile should be installed on U-type mounts.

Ceiling

The main designations of this model are PP and PPN (supporting and guiding ceiling profile). This profile also has a section similar to the letter n, but its section is much smaller than that of the wall profile. Inside this profile there are small shelves and additional ribs to make the frame of the structure more rigid. This profile also has a lower height, which saves space in the room. In addition, it is worth noting that the drywall used for the ceiling is thinner, which reduces the load on the profile.

It is worth noting that the transverse guides should be fastened so that the distance between the fasteners is no more than 900 millimeters.

In order to do this, you need to use spring mounts and U-shaped brackets. Crab clips can be used to more firmly connect the jumpers.

In rooms where chandeliers and other heavy structures are located, the frame should be made with additional cross beams. This will protect the entire structure from collapse. The size of the ceiling models: 60x27.75x50 mm.

Arched

The profile has a more complex structure, it has cuts on the sides, which increase the flexibility of the design. This aspect is an important plus for creating a flexible structure.

There are also a number of additional profiles. They are most commonly used for suspended ceilings and other decorative work.

To make the structure stronger in places of special bending, you can use a metal or plastic corner. This is necessary so that the structure can be bent at any angle. The corner whips can be from 2000 to 3000 millimeters. The width of each shelf can be of several types: 20.25.30 mm. The smallest bending radius of the structure must be at least 500mm.

It is worth noting that the whips themselves are quite an expensive thing, and in order not to overpay 1000 rubles for each pipe, you can create it yourself.

To do this, it is worth making many large cuts on the side edges at a distance of 40-100 mm from each other.

- The corner metal profile in the section forms a right angle, in which the central part protrudes slightly. The profile is usually used to decorate various plasterboard structures. Most often it is used to design corners in a structure. There are several types of them in total:

- Two shelves that have large and perforated holes, which are needed so that the corner looks good aesthetically and becomes part of the plaster. The rest of the structure rests on this angle.

- There is a drywall corner profile with a mesh inside. In order for the adhesion to be better, a mesh can be glued inside the structure, on which the rest of the parts will be held.

- Corner profile on a paper base. Two strips made of metal are glued onto thick paper. It is usually used in structures that carry the maximum load, for example, in window openings, various niches.

- The beacon profile is used as a base for plastering, the main purpose of this device is to level the surface. This profile looks like a metal bracket. The width and height of this profile is small, the widest is 1-3 cm.

Additional elements

Another important element used in the construction for leveling the surface with drywall is the suspension.

It also comes in several types.

- The perforated hanger looks like a metal tape measuring 125-60mm. The gimbal is divided into three parts. The central part allows you to attach the product to the ceiling, the side ones are used to hold the rest of the structure. A 90-degree bend is also made.

- Anchor suspensions are most often used to install suspended ceilings. The main advantage of this suspension is the height adjustment, which is very necessary for the installation of a false ceiling.

- Single-layer and double-layer connector. It is a connector that is used to hold together profiles that cross. It is also needed in order to make a suspended ceiling.

- Profile extender - a device that is used if the length of the profile is not enough. It looks like a brace measuring 110-58 millimeters.

How to choose the right one

In order to choose the right structure, it is very important to pay attention to what the profile is made of. For drywall, galvanized profiles should be used. It is the most durable material. In order to distinguish a quality profile, you need to focus on different aspects.

To build a good profile, there are some nuances that need to be observed.

- It should be galvanized, zinc should be almost one hundred percent. In this case, the frame will almost never corrode.

- Metal profiles, especially wall models, must be very durable. The wall profile bears the main load, and the profile must level the wall well and not corrode.

- The ceiling profile must be thick, otherwise the structure will take up too much space. The size of the product is 0.4-0.6 millimeters.

Tips & Tricks

In the process of buying and operating, be sure to use the advice of professionals in the field of repair.

- It must be remembered that walls and ceilings are never perfectly flat after roughing. In order to level the wall, you can use sheets of drywall, which should be at a certain distance from the wall. This will allow you to quickly level the wall without losing much room in the room.

- There will always be a small space between the insulation and the drywall sheets. This is necessary so that moisture does not collect between the wall and the structure. A so-called air cushion is formed between the sheets and the wall.

- There should be a gap between the wall and the drywall. This space is very important during construction, it allows you to fit insulation in this place.

- The frame is a necessary moment in the construction of arched structures, it is he who makes the structure more flexible.

- Drywall sheets do not have a high strength threshold. If you need to fix some heavy structures, you should use a profile frame, without it, the structure will simply break. The fasteners must be in contact with the main frame.

Auxiliary profiles

It is also worth remembering that there are auxiliary profiles. They are used during finishing work together with drywall and come in several varieties.

- Reinforced thick profile well suited for rooms with a heavy partition between doors. It is also well suited to increase the rigidity of a structure. Most often they have a fixed length - 3000-4000mm, but if you wish, you can buy a product with a length of 6000mm. The height of the ribs is standard - 40mm, the thickness of the walls differs from the usual profiles and is 2mm.

- Protective metal corner. It serves to protect the corners from damage during operation. After the installation work, the corner is putty, and also covered with finishing paint. In order for the paint and solution to penetrate better, a large number of small holes are used. The length of such corners is the same - 3000mm.

There is another version of the protective corner, which is not placed under the putty, but covered with plaster mortar. In order for it to better penetrate inside, a special mesh is used.

Fasteners and various connecting elements

During the manufacture of the frame, it is very important to correctly connect the structure. Sometimes this can be done quite simply by inserting profiles into each other, but this is not always possible. In such a situation, it is worth using fasteners of various types:

- Duplex connectors. This design is needed in order to connect two parts at an angle of 90 degrees in a different plane. Most often, these parts are made of galvanized steel in the form of a flat pattern. Before starting the installation work, this thing will need to be bent manually at the desired angle, the width of such a connection is 60mm. In order to secure the structure, screws must be screwed into the side parts.

- Sibling connectors or crabs. These fastening systems are used to connect two identical models at an angle of 90 degrees. They can be found ready-made in almost any store. Installing this part will not present any problems, it simply snaps into place on the back of the structure.

If the load on the frame does not exceed 20 kg per square meter, then an ordinary latch will be enough to fix the structure. If the load is greater, then self-tapping screws should be used to strengthen the fixation.

Direct suspensions

They are used during the installation of various structures that are used for the ceiling and for attaching vertical profiles to the wall. These items can be found in any store. They are made in the form of flat plates, and in order to install them, you have to bend them by hand in the shape of the letter P.

To attach a vertical or rack-mount profile, it is worth placing it between the suspension, and use self-tapping screws for fastening. The standard height is 125 mm, but you can also find non-standard suspension sizes - 75 or 100 mm. The load on such a structure cannot exceed 40 kg.

Anchor or spring hangers

They are used only in a situation where you need to dismantle a suspended ceiling. These structures allow the height of the ceiling to be adjusted and are usually used for high ceilings. The length of these suspensions can be 200-300 millimeters. The maximum load can be 25 kilograms, if the load is greater, it is worth using additional fasteners.

How to identify a marriage

There are the following types of rejects among the profiles for GLK.

- The metal does not have the required thickness. This disadvantage is very significant. The strength of the structure depends on the thickness of the metal.

- If there are traces of rust, they are also worth paying attention to. This means that the metal is poorly processed, which also leads to negative results.

- Incorrect dimensions. This is one of the most unpleasant types of marriage, due to which it is impossible to properly assemble the structure.

- A bad notch is also a disadvantage, since it makes it difficult to screw in the screws correctly.

The main thing to look for when repairing using drywall sheets is the correct choice of frame.

You should also calculate the weight of the structure in advance, since the choice of a profile and fastening systems for it depends on this. If you choose everything correctly, then the repair will not be too much of a problem.

For more information on the types and sizes of drywall profiles, see the video below.

The comment was sent successfully.