All About Cutting Marble

Everyone at least once in their life has seen luxurious apartments with a fresh renovation in a modern style. Have you noticed what kind of material hosts often use to impress guests? Of course, marble. Marble bathtubs, sinks and tables are all the epitome of beauty and luxury. In our article, we will talk about cutting this difficult material.

Peculiarities

Marble is usually used in the interiors of apartments and houses and allows you to give them pomp and luxury. This stone is almost never used in the external decoration, which is due to the peculiarities of the Russian climate. Thanks to modern high-tech equipment for cutting marble, unique fireplaces and countertops, columns, luxurious stairs are created. To decorate a room, apartment or house using this material, you need to know its main features - these are high strength and a wide selection of shades.

The stone is produced in the form of tiles of all sizes that will last more than one year, even in a room with a high level of humidity, for example, in a bathroom. In addition, marble is resistant to temperature extremes and does not crack - thanks to this, it can be used to decorate a fireplace. However, the coating can change color with prolonged exposure to water.

To prevent this from happening, it is necessary to properly prepare the material and process it with a special compound.

Cutting methods

Professionals are engaged in cutting stone, it is quite difficult to do this at home.

Mechanical

The mechanical method of cutting involves sawing, chipping or destruction of individual parts of the working surface of the marble. Chipping is used when it is necessary to achieve natural stone images in the interior. Within the framework of this method, cuts of rope, disk and strip types are used.

Rope sawing assumes wider possibilities of working with almost all types of stone, not limited to the peculiarities of their structure. There are three ways to use wire sawing: using abrasives, using reinforced washers, wire rope cutting. Abrasive cutting is the most popular because it does not take much time, while being characterized by a sufficiently high cutting accuracy.

Physicomechanical

Physicomechanical methods involve the use of electricity or gas burners. This is usually common in the manufacture of marble monuments, since detail is important as well as precision. Within this group of methods, waterjet and diamond cutting of marble have earned a good reputation.

The combination of clarity of the result, convenience and practicality, safety ensured the success of these methods.

Each method has its own advantages and disadvantages. The advantages of waterjet cutting are as follows:

- smooth edges and cutting accuracy;

- practicality and convenience;

- minimum amount of waste;

- no negative temperature effects on marble;

- safety of use;

- ease of use with artistic cutting.

There are also disadvantages:

- high cost of the work performed;

- lack of efficiency - slow impact on the material;

- limited functionality of tools designed for waterjet processing.

Pros of processing with diamond discs:

- high cutting accuracy;

- efficiency of work;

- relative noiselessness;

- does not cause significant harm, no chips on the stone;

- spraying can be applied both to the entire surface and to its individual parts.

Disadvantages of diamond cutting:

- sawing only in a straight line;

- the need to re-process the sawing line;

- impossibility of processing the enameled structure of marble - leads to cracks.

How to cut?

As a rule, saws, machine tools and other industrial and semi-industrial equipment are used in household cutting. Each of these types of tools can be powered by electricity, diesel or manual control. The most preferred among the craftsmen who carry out sawing at home, hand saws - this is due to their affordable price. They are more practical in comparison with professional machine tools and industrial tools, since they do not require such physical activity to perform a small amount of work.

An electric saw is more productive, but less powerful than the same gasoline-powered tool options. Among the existing machines for cutting marble there are both manual equipment and stationary ones. The first options are quite mobile and convenient for home use, while the stationary ones are represented by a complex mechanism - an engine, frame and transmission, an active element. Professional are highly durable and durable.

Each model of marble cutting equipment has a special disc, which is an edge and a metal body. The edge is diamond-coated, which affects cut quality and productivity. The speed of rotation of the blade and, accordingly, the speed of cutting is determined by the type of equipment, as well as by the power. The higher the number of revolutions (speed), the stronger the friction and the faster the processing of the marble.

In this case, the disk is constantly heated, the sputtering is erased, therefore the amortization is higher.

Description of technology

A compact saw will be most suitable for home cutting (wall, floor and sink trimming). For production work, on the contrary, it is better to give preference to pavement or multi-disk. A one-time rental of a cutting machine, which is equipped with a water cooling function and a diamond wheel, will be acceptable. The machine cannot be used without cooling, otherwise the stone can be severely damaged.

You cannot work without personal protective equipment - special glasses, gloves and headphones. In addition, preliminary preparation of additional tools is necessary - sandpaper, diamond discs of different sizes, coolant, a grinding wheel, a scoop and a brush for cleaning. Preparing the diamond blade requires checking the coolant supply to prevent overheating of the equipment - water must be directed directly onto the rotating blade.

Also, the liquid provides additional protection for the texture of the marble.

The sawing line is marked with tape or a special marker, after which the marble is fixed in a cutting mechanism with a cooled circle. It is the correct and accurate placement of the material that ensures the safety of the master's work. The tiles must be fed slowly to avoid overloading the machine. Do not direct the marble to the disc too quickly, otherwise it may be completely destroyed or injured by the master. The tile is carefully guided forward until it is completely cut by the disc.

The surface formed as a result of sawing is smoothed with a diamond wheel with a small diameter or a grindstone. The integrity of the material is directly dependent on the smoothness and accuracy of the operator's movements. The work ends with the use of sandpaper - you can use both dry and slightly moistened. It is recommended to start with the 120th paper, gradually changing the types up to the 2500th.

This will maximize the smoothness of the cut.

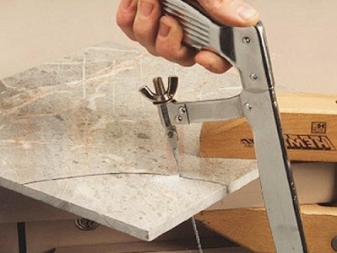

At the end, the waste is cleaned on all edges of the marble and the cooling water is removed. It is better for novice craftsmen to first practice on rough fragments, and only then use the finishing material. Particular attention should be paid to safety, including the grounding of electrical appliances. A more sophisticated technique is sawing the marble using a hacksaw combined with a diamond-coated wire. The complexity of execution, in comparison with the use of conventional electrical appliances, lies in the independent and rather skillful organization of the coolant supply.

Frequent mistakes

Among the most common mistakes are the following.

- Choosing a cheap diamond blade, which can negatively affect the accuracy and quality of the result, as well as spoil the material. Some diamond blades are not suitable for fine work with marble, but for concrete. Lots of chips, hard knitting are just a few of the consequences that inappropriate discs can lead to.

- It is necessary not to finish the stone to the very end, but to leave the "comb". After that, you need to turn the workpiece over and cut from the upper side of the same place. In this way, surface chipping can be avoided.

- Overheating of equipment. To avoid this error, the cutting must be done with coolant supply, which will also prevent the marble surface from blackening. A cooling water supply is recommended when using solid and segmented diamond discs. "Turbo" discs or discs with laser-welded segments do not require additional cooling.

- At the stage of purchasing equipment, you need to make the right choice between high productivity and precision cutting marble. Otherwise, you can choose completely unsuitable discs - solid ones are required for ultra-precise work, segmented ones - for urgent ones, but at the same time they do the work not of high quality, with a large number of chips.

- Difficult cuts need to be done in a stepwise manner. and gently break with your hands where the circle could not reach. Then process and grind.

The process of cutting a marble slab at home is presented in the video below.

The comment was sent successfully.