Features of marble chips

Marble chips are a versatile building material made from marble granules and a transparent adhesive base. It is popular in various fields and has many operational advantages.

Description

Marble chips are a natural mineral, crushed to the state of flour or crystals, the size of which on average varies from 0.5 to 2 cm. The particle size is determined by the external section. During production, the material goes through the stages of drying, dusting and sorting. Outwardly, it resembles sand, in origin it is a crushed stone.

Basically, the mineral is mined in the quarries of the Trans-Urals, Western Siberia, Altai, in the Krasnoyarsk Territory. The stone itself is formed during the connection of rocks under the influence of pressure and high temperature. It can have different densities, consists of dolomite, calcite, or their compounds. It may contain suspensions of organic origin, which determine the shade of the mineral.

Marble chips are made from illiquid pieces of marble, as well as its waste. The product goes on sale that meets the requirements of GOST 22856-89. The size of the granules is directly related to the mass: the larger the crumb, the more it weighs.

The flakiness of the marble chips indicates its quality. The percentage of acicular and lamellar grains in the total mass should not exceed 35%. The specific (volumetric weight) is usually 2.74 kg / m3, the bulk density is 1.4-1.6 kg / m3. The frost resistance index varies from 25 to 300.

Advantages and disadvantages

Marble chips, or the so-called living stone, are a unique durable material that has a lot of advantages:

- has strength and resistance to mechanical stress and shock;

- not afraid of exposure to sunlight, does not change color during operation;

- more technologically advanced than many plastering materials, vapor permeable, easy to rub;

- lends itself to polishing and grinding, does not spark when rubbed and hard touched;

- having an adhesive component, it has elasticity, resistance to scratches and cracks;

- environmentally friendly and safe, can be used in residential and non-residential premises;

- fireproof, has high decorative qualities and is not afraid of temperature changes;

- is a suitable anti-vandal coating for rooms where animals live.

Chipped marble is used as a topcoat on any type of substrate. For example, it can be used to decorate reinforced concrete panels, walls made of lightweight concrete, drywall, fiberboard, chipboard, plywood, wood. It can be applied to floors covered with water-based paint or acrylic paint.

Its use strengthens any joints, they become wear-resistant. Dyes are created from it, as well as various building mixtures. It does not accumulate radiation, it can be used for mulching and drainage of plants, keeping moisture in the ground. This material masks the imperfections of the base (curvature, cracks).

In addition, marble chips are considered a natural antiseptic. The crushed rock blends perfectly with most building materials and fits well into any interior style.

However, along with the advantages, marble chips have several disadvantages. For example, working with her does not tolerate delay. It must be laid in one layer at once so that the joints are not visible. Otherwise, the surface looks unaesthetic.

Before revealing the surface, you need to take into account that dismantling the crumb is a laborious task. It cannot be removed as easily as, for example, wallpaper.

Such material should not be applied to the surface of ferrous metals - this leads to corrosion. In order to prevent this problem, they resort to priming the surface immediately before facing. For all its strength and durability marble chips are not resistant to food acids.

Depending on the type of work, the finished cladding may require varnishing. It is better to remove stubborn dirt from the surface with soapy water. Rubbing the finish frequently with a coarse abrasive is not recommended.

Among other disadvantages, it is worth noting the severity of the finished base. A lot of mix may be needed for quality work. A large layer makes the walls heavier, creating additional stress on the floors. In addition, the work does not allow for alterations and adjustments.

Dimensions (edit)

The size of the granular mineral rock can be different:

- varieties with a grain size of 0.15-2.5 mm are called marble sand;

- small chips have a particle fraction ranging from 2.5 to 5 mm;

- large chips have a particle size of 5 to 10 mm;

- material with a crumb section of 1 to 2 cm is called marble crushed stone;

- on sale there is a variety with a minimum granule size (about 0.15 mm) - it is called marble flour.

The choice of one or another type depends on the scope of the material.

Species overview

In addition to the size of the fraction, the varieties of marble chips differ in the type of solvent and the method of staining. The shape of the faction may vary. For example, in the assortment of sellers you can find a tumbling mixture, which is a processed stone that resembles natural pebbles.

Such a stone is distinguished by its smooth shape and luster. Tumbled chips create a glare in the sun, are used in fountains, aquariums and swimming pools, contributing to the creation of an atmosphere of sea tranquility. This eco-friendly material can have a different fraction size (20-40, 10-20 mm and less).

The finishing material is sold in bags. The weight of the bags can be 2, 10 and 15 kg. At the same time, colored varieties are most often sold in small bags. In addition to them, gray and white crumbs with a particle size of 5-10, 10-20 mm are sold in a volume of 2.5 kg.

White

A white mixture consists of cement grade 400, crumbs, slaked lime, mica, marble flour. Decorative plaster with the texture of natural stone is created from this material. It is used in the decoration of plinths, facades and columns. It is perfectly tinted, due to which it can be given almost any desired shade for the chosen color scheme of the interior or landscape.

White cement is produced from it, it is used in sand filters to stabilize the water composition. For these purposes, a variety with a fraction size of 1 to 3 mm is suitable. It is bought for making flowerpots and figurines, decorating the adjoining territory of a country house or summer cottage with them. The mixture helps to improve water quality by binding carbon dioxide. White crumb-sand is used for very hard water, in which there may be suspensions of manganese or iron.

Gray

Gray marble chips have the same properties and performance characteristics as white and colored counterparts. Its composition can be changed by adding, as with other varieties, different impurities. For example, you can change the texture of a stone by adding malachite, onyx, quartz and other natural stones to the composition.

Unlike a white analogue, gray marble chips are most often used for the production of anti-icing reagents. In addition, it is used in landscape design, masks imperfections in land plots and places of depleted soil where plants grow poorly. It is a useful material that can be used as a mineral fertilizer.

Colored

Colored marble chips are classified as carbonate rocks. The colors of such a mineral can be different:

- pink;

- green;

- red;

- black;

- orange;

- beige;

- blue;

- brown;

- yellow.

The shade depends on the color of the stone itself and the type of impurities.

For example, silicates containing iron color the stone greenish. Iron oxide gives the crumbs a reddish tint. The blue-black variety contains a water-dispersed sulfide.

Bitumen and graphite can give blue, grayish and black tones to marble chips. The brown or yellowish mineral contains admixtures of limonite and carbonate. However, the color can be not only multi-colored, but also striped. In this case, the color saturation does not depend on the size of the fraction.

If desired, the crumb can be combined with each other, creating unique mosaic patterns. Manufacturers of marble chips independently give the material the desired color, using paints based on epoxy resins. Such building material is more expensive than its counterparts. He is in special consumer demand. Moreover, the shade can be changed or made brighter.

Remarkable is the fact that the color can determine the price of the marble chips. For example, the gray variety is considered the cheapest option. Blue chips are the most expensive of all, since such a mineral is found in nature less often than other analogues. More recently, blue marble was mined mainly in Argentina and Kenya. Today it is mined in Russia, and the quality of domestic stone is not inferior to imported counterparts.

Applications

Chips of marble are used in various fields, for example, in the manufacture of mosaic floors. Besides, decorative elements for the interior, monuments and even sculptures are made from it. It is an excellent material for the production of furniture with a unique surface texture. It is used for interior and exterior finishing works.

Marble chips are applicable for:

- decoration of various products;

- decoration of landscape design objects;

- sprinkling of roads in winter to avoid icing;

- water filtration;

- dumping of filling and nuclear power plants;

- filling the bottom of the aquarium;

- dumping tracks between the beds;

- decoration of flower pots and borders;

- decoration of walls, window sills, countertops;

- decoration of reservoirs and pools.

In addition, marble chips are added to porcelain and ceramics products, giving them greater strength; they decorate flower beds, panels and border ribbons with it, as well as paving slabs, flowerpots and thermal panels. It is an excellent material for finishing floors and facades.

Stairs are made of it, with its help, mosaic floors are decorated. To make the finish look interesting, mosaic patterns are created using veins of bronze, glass or copper. To achieve the best result, when creating the floor, take marble chips of different colors and sizes. So you can beat the color and texture of the coating.

The granular mineral can improve the drainage of the area. For these purposes, it is poured around garden trees, not forgetting to lay geotextiles. In this way it is possible to avoid overheating of the soil and the growth of weeds.

The original use of colored marble chips is to create a so-called dry stream to decorate the landscape. The imitation of a pond is achieved by mixing the material of different blue shades. Surrounding it with plants and flowers, you can create a unique design for a summer cottage, a garden. The material can be rinsed as needed by collecting the dirty layer onto the backing.

Payment

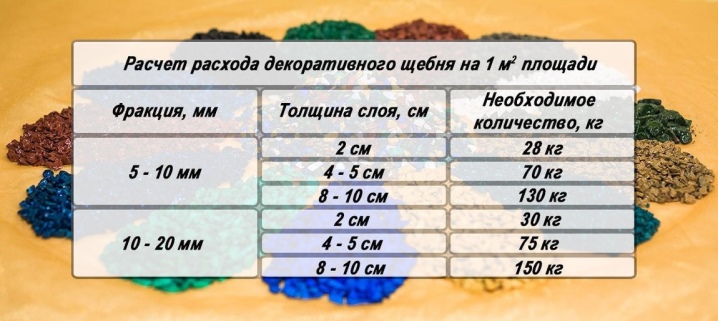

The calculation of the amount of marble chips depends on the scope of its use and the layer of application. For example, if the mixture is purchased for decorating a garden or carrying out construction work, the average consumption per 1 square meter will be approximately 40-50 kg. With a layer of 3 cm, experts working with this material recommend buying 60 kg per 1 m2.

The required amount can be calculated using an online calculator. In addition, you can consider the following scheme.For 1 square meter of tiles with a thickness of 3 cm, 80 kg are needed. For crumbs, a coefficient of 0.75 is taken. This means that 80 x 0.75 = 60 kg will be needed to carry out the work.

Knowing the amount of raw materials per 1 square meter, it is easy to calculate how much material is needed in total. It is advisable to take the mixture with a margin of 10-15%. So you can not worry that it will not be enough at the most inopportune moment. The surplus can be used for other needs (for example, for filling around a tree, decorating flower beds, creating a decorative imitation of a pond).

For tips on applying marble chips, see the video below.

The comment was sent successfully.