Features of artificial marble

Unfortunately, not every person has the opportunity to use natural marble as a decorative design. The reasons for this are the high price of the finished material and the high cost of production and cutting of the required dimensions. But thanks to modern technologies, it was possible to develop an analogue of natural stone.

What it is?

Artificial marble is a decorative material that is a high-quality imitation of natural stone. For its manufacture, polyester resins are used, as well as stucco and concrete familiar to everyone. Dyes, hardeners and other components are added to the bases presented, when combined, a spotted pattern with characteristic marble stains appears, completely repeating the effect of a natural stone.

However, in addition to the picture, additional components of the composition give the material unique properties: strength, fire resistance, environmental friendliness, chemical resistance, shock resistance and heat resistance.

Artificial marble has a considerable list of advantages, however, it received the main popularity for its reasonable price, a varied palette of colors and ease of maintenance. These qualities made it possible to expand the scope of the material. Today it can be found not only in residential premises, but also in offices, as well as in schools, canteens, and medical institutions.

Some consumers, when choosing a decorative material for finishing different surfaces, compare artificial marble, granite and quartz. But they cannot determine which material is better. For example, granite is strong, durable and rich in color. The disadvantage is the inability to use abrasive detergents.

Marble is also durable, does not cause an allergic reaction, and is pleasant to the touch. The downside is the difficulty of removing stubborn stains. Quartz, unlike artificial marble and granite, is made from natural materials, has increased strength and, with proper care, will last for more than a dozen years. Therefore, it is impossible to say specifically which material is better.

Manufacturing methods

Making artificial marble with your own hands is difficult, but possible. The main thing is to decide which technology is most suitable for home production.

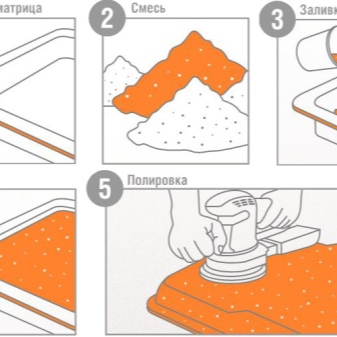

Cast marble

This method is based on the use of polyester resin and mineral fillers, for example, crushed quartz. For self-production, you will need to make a solution consisting of polymer concrete and butacryl. The first component is made by combining 25% resin and 75% neutral mineral. The second requires mixing AST-T and butacryl in equal amounts with the subsequent addition of quartz. For work, you will also need sand, a pigment of the desired shade, a gelcoat and a plasticizer.

Having prepared the required components, you can get to work:

- the matrix is lubricated with gelcoat;

- while the form dries, a solution is prepared;

- the mixture is poured into a matrix mold;

- the container is covered with a film and set aside for 10-11 hours;

- the hardened stone remains to be removed from the matrix mold and held in the air.

The resulting piece of marble can be processed or left unchanged.Unfortunately, this method of home making requires a large financial investment, so most builders prefer to use other options.

Whetstone (gypsum) method

Artificial marble, made according to the presented technology, is a plaster piece based on a mass of glue and water. A prerequisite is grinding the finished piece of gypsum, which creates an imitation of natural marble. It is noteworthy that very little financial investment is required to create gypsum marble. The main thing – follow instructions:

- gypsum and glue should be kneaded in a container with water;

- melted resin is poured into the mixture;

- the gypsum mass must be stirred by adding a tint pigment to it;

- then the mixture must be thoroughly mixed until streaks appear, imitating the pattern of natural marble;

- the liquid should be poured into a plastic matrix;

- excess mixture should be removed;

- the mixture in the form must be set aside in a secluded place for about 10-11 hours;

- after a specified time, the piece can be removed from the matrix;

- to impart water resistance, the surface of gypsum marble should be treated with potassium silicate;

- then the hardened stone is dried and polished;

- the polishing should be finished only when the surface of the produced marble has a mirror effect.

This method of self-production of artificial stone is the most affordable and most convenient. Thanks to the gypsum base, the marble material turns out to be strong, while having a low weight.

Concrete filling method

The proposed manufacturing technology, along with the plaster method, is very popular. And all thanks to the simplicity of work and environmental friendliness of the materials used in the production. We suggest that you familiarize yourself with the step-by-step instructions for making concrete marble:

- it is necessary to lubricate the matrix with gelcoat, then set the form aside while waiting for complete drying;

- a concrete mass is prepared (2 parts of sand, 1 part of cement, water and pebbles);

- clay and slaked lime are introduced into the mixed concrete;

- pigment is added, then mixed thoroughly;

- a painted mixture is poured into a horizontally installed matrix in small portions;

- the excess mixture is removed with a small spatula;

- the filled matrix should be covered with foil and left in a warm room for at least a day;

- after hardening, a piece of concrete should be removed from the matrix and processed with a grinder.

When the question of the need to decorate a particular surface with marble arises, it is best to use the plaster or concrete method. Of course, if the product is to have impressive dimensions, it will not work without help.

Well, if it is not possible to make a stone on your own, you can always buy it, especially since the cost of imitation is much lower than the price of a natural stone.

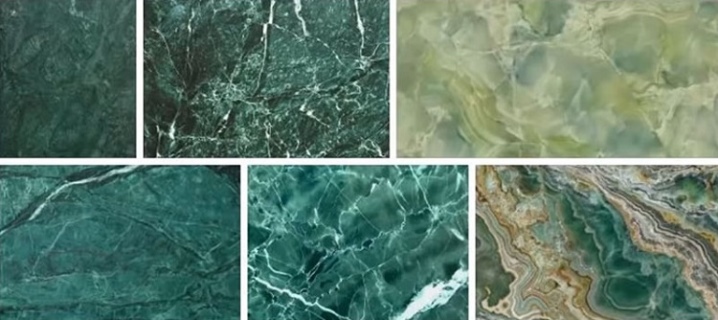

Species overview

Today the shops offer a huge selection of artificial marble. The items displayed in the windows have a different color palette. Moreover, each presented option is classified according to composition, variety and manufacturing method. The main ones include casting, liquid, sedimentary and milled types.

Casting

The most popular type of artificial marble, which can be purchased or made by yourself. However, as mentioned above, you will have to spend a considerable amount for home making. The foundry variety of marble is based on a mineral type filler and polyester resin.

Liquid

This variety can be called relatively new. Liquid marble is flexible, lightweight and, most importantly, environmentally friendly. It can be cut with scissors and split with a knife. Subject to the rules of installation, it will be possible to obtain an absolutely smooth surface that does not have connecting seams.That is why liquid marble is often used to decorate non-standard items.

When decorating residential premises, this material is ideal for decorating walls instead of wallpaper and Venetian plaster.

Oselkovy

As mentioned earlier, this type is a plaster base, painted in the desired color. The surface of the material has a mirror finish. In the manufacture of gypsum marble, special components are added to the base that slow down the hardening process. Diluted polymer glue is used as an analogue of retarders. The distinctive features of the presented type of material are low weight and high level of strength.

The finished stone can be used as a decoration for walls and ceilings. With it, you can even build small structures that do not require a large load. Another positive feature is the improvement of the microclimate. Gypsum marble absorbs excess moisture and, conversely, recovers moisture when the room gets too dry.

Ground

This type of artificial marble is also called chipped. In its manufacture, crushed white marble chips are used, so the stone has a light shade. Crushed marble has a high level of strength and low chemical activity. It easily tolerates exposure to ultraviolet radiation. But the moisture resistance of the chipped material is quite low.

How is it used?

During the renovation, when the question of interior design arises, the owners of premises increasingly prefer decorating with artificial marble, since:

- it is easy to find the desired shade;

- the cost of the stone is quite democratic.

Due to the variety of types of artificial marble, this material can be used for cladding the facade of a large building, as well as highlighting windows and doorways. When decorating the interior of houses and business centers, the presented material can be placed on the steps of the stairs, and decorated with columns.

By the way, modern technologies have helped to combine artificial stone and paving slabs into one whole. And therefore, at the entrance, a person can be greeted by a chic path in the form of a patterned mosaic, on the surface of which frost does not appear during frost.

Much more often, artificial marble is found in residential buildings and apartments, where it plays a decorative role in bathrooms, bathrooms, kitchens and other rooms. Moreover, if in the living room and bedroom artificial marble is a window sill, in the kitchen it will be presented in the form countertops, bar counter, dining table and sink.

And in the bathroom itself bathing bowl can be made of artificial marble. In addition, artificial marble can become an irreplaceable decor for a summer cottage. This material can be made fountain, benches, flowerpots, coffee table.

Care Tips

It is worth remembering that artificial marble requires special care:

- you can not apply to it detergents based on drying oil;

- remove dirt from imitation marble with a soft cloth;

- do not use hard brushes to clean the mirror surface.

And in order for artificial marble to retain its beauty for a long time, you need to heed some advice from experienced housewives:

- for high-quality care of artificial marble, gel detergents should be used;

- a solution of 3 liters of water and one cap of liquid soap will help to maintain the glossy effect, which should be rubbed in with a dry cloth.

Observing these rules, it will be possible to preserve the luxury of artificial marble, even made by hand.

In the next video, you will see the technology for the production of artificial marble.

The comment was sent successfully.