Penoplex adhesive: selection criteria

Penoplex is a heat-insulating material widely used in construction. For fixing the plates, modern adhesives are most often used, the range of which includes several dozen items. How to choose the best option and make the right choice, read this material.

Peculiarities

Penoplex is a foamed polystyrene with a homogeneous structure of small air cells. At the moment, there are only two types of foam with different densities on sale: 35 and 45 kg / m³.

The difference between the two materials is significant, ranging from properties and technological qualities to their purpose:

- Penoplex 35 kg / m³ is designed for thermal insulation in industrial and residential buildings;

- Penoplex 45 kg / m³ is used in the construction of highways, gas and oil pipelines, in railway construction.

In addition, the material is used to insulate facades, roofs, foundations and internal walls of buildings.

Penoplex technical characteristics:

- strength;

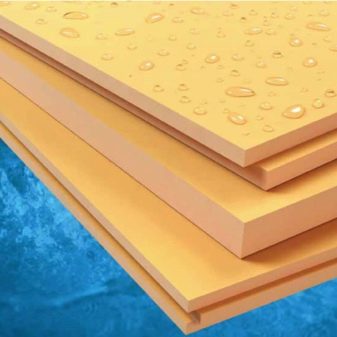

- high resistance to moisture;

- low level of thermal conductivity;

- resistance to mechanical stress;

- ease of installation and processing;

- weak chemical activity;

- hardly flammable;

- environmental friendliness;

- durability;

- affordable cost.

The installation of this insulation is carried out using a special glue, the choice of which determines not only the duration of the material's operation, but also the health of people living in the house.

Types of adhesives

All adhesives for penoplex on the market have a high level of adhesion. Thanks to this, there is a reliable adhesion of the composition to the surface, thereby strengthening the finish and increasing its quality.

As a rule, adhesives come with instructions for use and a brief description of the technical characteristics, which include:

- temperature parameters for installation and further operation;

- air humidity indicators;

- what type of surface is this material intended for;

- type of surface to be insulated.

The range of adhesives for penoplex is divided into several types.

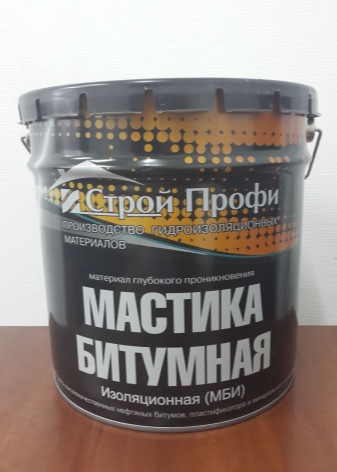

Bituminous mastic

This material is a thick bitumen-based mixture that retains its original properties even at sub-zero temperatures. Bituminous adhesives are widely used in construction, in particular, for waterproofing foundations. In addition to its direct purpose, it is an excellent hydrophobic joint filler during the installation of foam.

When working with this material, it should be borne in mind that the mastic does not need to shrink and has a high level of adhesion to mineral and metal surfaces.

It is preferable to work with a spatula or a spatula.

Liquid Nails

This material is suitable for working with any surface. However, the work should take into account the peculiarity of the place where the repair work will be carried out. For installation inside a building, conventional compounds are used, but for external insulation, specialized means are used that are resistant to frost and temperature extremes.

On sale, the composition is presented in tubes. It is best to apply to the base with a "snake" over the entire surface of the sheet. For gluing the foam to the surface, just 10-20 seconds is enough - "liquid nails" have time to grab during this time.

The only negative is the rather high price of the material.

Mineral

Mineral adhesives are presented in the form of dry mixtures and are diluted with water to the desired consistency before use. They are distinguished by high adhesion and go well with concrete, brick and gas silicate surfaces. Their advantage is their high plasticity, which allows the material to be applied in a thin layer.

Apply with a notched trowel. After drying, they do not "shrink", retaining their volume.

For outdoor work, there are special moisture and frost-resistant compounds.

Polyurethane

Such adhesives are produced in special metal cylinders and can only be used with the help of special equipment - a gun for polyurethane foam. When applied correctly, the material will lay flat on the substrate in even zigzags, allowing a bond to be achieved over the entire surface area.

Such compositions are distinguished by quick setting - it is enough to hold for half a minute, and the material will be firmly glued. But at the same time, the elasticity of the material remains for about 15 minutes.

Manufacturers and reviews

The modern building materials market offers many adhesives for foam. We offer you to familiarize yourself with the most popular and high-quality products from different manufacturers.

Tytan

The Polish company Selena quickly gained popularity in our market. And all thanks to the high quality of products and loyal pricing policy. Almost the entire range of goods is presented in the form of adhesives and sealants, one of which is Tytan universal glue.

The Professional Styro 753 series is most suitable for working with penoplex., resistant to precipitation, temperature extremes, moisture. This adhesive does not need to shrink and ensures a tight adhesion of the material to the surface.

Cerisit

The popular company Cerisit, known as one of the best manufacturers of building materials, offers a whole line for working with penoplex.

Experienced professionals select high quality formulations.

- Cerisit CT84 - special foam for foam, used in facade cladding. It tolerates high and low temperatures well (from -10 ° С to + 40 ° С). Differs in the speed of drying - in the warm season, the composition hardens after 2-3 hours. You can carry out the work using an assembly gun. This composition is loved by consumers for the harmonious ratio of affordable cost and excellent quality.

- Cerisit CT83 - dry mix for laying slabs. The drying time is much longer than the previous material - as many as three days at positive temperatures. The composition is applied using a notched trowel. The approximate consumption of the mixture is 6 kg per m2. The only negative is that the material does not tolerate cold well, therefore, if the temperature is below zero, work cannot be carried out.

- Cerisit CT85 - reinforcing glue used for gluing and subsequent reinforcement of tile material. The product can only be used at positive temperatures - from +5 to + 30 ° С. The mixture must be used within two hours after mixing. Approximate consumption of the mixture: 6 kg / m2 - when gluing; 5 kg / m2 - with reinforcement.

"Moment"

This material is universal for gluing foam boards, as well as for creating a protective reinforcing mesh. Differs in a high level of adhesion, elasticity, moisture resistance, frost resistance. Does not need shrinkage and tolerates both low and high temperatures.

Master Termol

A cement-sand mixture for working with penoplex has many advantages.

- First, it has good contact with cement and lime substrates.

- Secondly, it adheres perfectly to polystyrene foam substrates. In addition, the material is highly plastic, frost-resistant and is considered an environmentally friendly product.

Most reviews from experts say that the quality of this material can be equated with more expensive funds, although its pricing policy is much more loyal.

ProfLine ZK-4

Adhesive for reinforcement and installation of slabs on concrete, cement and plastered surfaces. The composition includes special substances that enhance the bonding of the material to the base. After hardening, it becomes invulnerable to frost, moisture and external irritants. For the production of ProfLine ZK-4, high-quality raw materials are used, due to which this product has all the above advantages.

Penoplex Fastfix

It is a high-quality and durable tool for installing sheets of foam insulation. Suitable for working with surfaces made of concrete, aerated concrete, bricks, ceramic blocks. Like the previous compositions, it has high adhesion, but is incompatible with foil base, bituminous surfaces, plastic films, Teflon and silicone.

The use of Penoplex Fastfix allows you to speed up the installation process and make it of higher quality.

How to choose for different surfaces?

The choice of the optimal adhesive depends on the type of surface.

- Dry compounds are suitable for outdoor insulation. They adhere well to stone and brick substrates, as well as plaster. When choosing dry mixes, you should pay attention to the release date and the integrity of the package - it must be hermetically sealed. Otherwise, the quality of the composition may suffer.

- Polymer and bitumen mixtures are used in waterproofing works.

- There are special polyurethane adhesives for reinforced concrete surfaces. And also such compositions can be used for wood bases.

- For metal work, liquid nails, silicone sealants, and polyurethane foam are suitable.

- Liquid nails are used when laying foam on plywood, corrugated board, plastic.

If you plan to install thermal insulation on the walls and ceiling, then it is better to use polymer mixtures. Mineral adhesives are intended for outdoor use, but for indoor use it is better to choose polyurethane. The latter are especially effective for arranging floor insulation.

If the work is planned to be carried out on a dry surface, then high-quality gluing is given by compositions based on gypsum and cement. The only drawback is that almost immediately after mixing, they begin to harden, so the work must be carried out quickly. This creates some inconvenience in the work. Therefore, it is better to knead the composition in small portions.

The speed of drying of the glue creates certain conditions during internal work. In addition, almost all adhesives for penoplex have an unpleasant odor, which is difficult to erode later.

There is a universal composition suitable for almost any surface - glue-foam. Suitable for interior and facade work, floor and ceiling insulation. For a strong "setting" of the material with the base will be enough only 15 minutes, and you can work even at sub-zero temperatures.

Application Tips

Depending on the type of surface, the method of gluing foam boards is chosen.

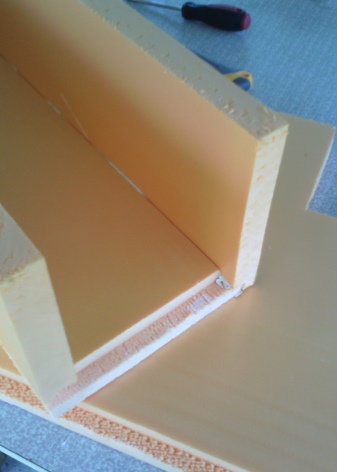

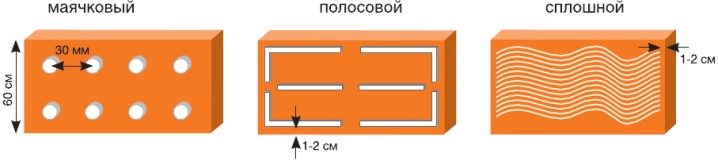

- Striped. The mixture is applied along the perimeter of the base in strips at a distance of 20 cm from the edge. At the same time, it is necessary to ensure that so-called air plugs do not form between the boards when gluing - this will reduce the quality of thermal insulation.

- Beacon. The mixture is applied in stripes along the entire perimeter of the surface and pointwise in the center of the plate. The stripes should not be continuous.

- Solid. The surface is completely covered with the mixture using a notched trowel.

Before directly applying the glue to the substrate, it must be prepared.

- How to clean from dirt, prime (if specified by the manufacturer) and dry.

- For greater adhesion, it is recommended to lightly sand the surface of the foam.

- It is not recommended to glue the joints of the insulation. Their connection is carried out using EE adhesive tape.

It is also important not to forget the peculiarities of working with adhesives.

- The consumption of the mixture is indicated on each package of adhesive. However, experts recommend purchasing funds with a margin.Especially if it is planned to process uneven surfaces, or if the work will be carried out by a person who has no experience in laying foam.

- For beginners, it is better to use long-drying adhesives, as during the work, you may have to move or level the slabs.

How to fix the insulation panels with penolex glue, see the video below.

The comment was sent successfully.