Characteristics of TechnoNICOL foam glue for expanded polystyrene

When performing construction work, specialists use different compositions for fixing certain materials. One of such products is TechnoNICOL glue-foam. The brand's product is in high demand due to the quality and high performance for which the manufacturer is famous in its segment.

Features and characteristics

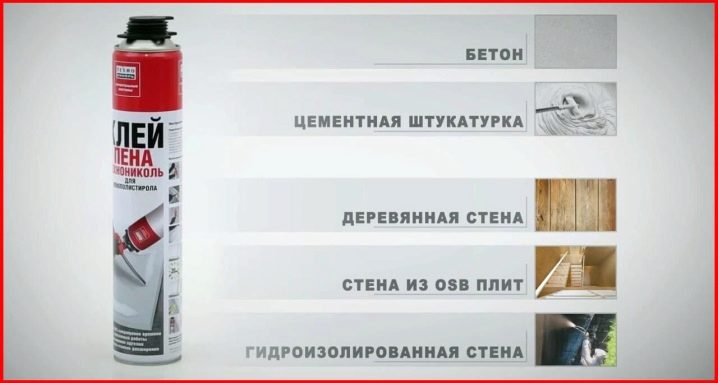

Glue-foam "TechnoNICOL" is a one-component polyurethane adhesive, with the help of which the installation of expanded polystyrene and extrusive boards is carried out. It has high adhesion rates, which makes it suitable for concrete and wood substrates. Due to special additives, the polyurethane foam is fireproof. It can be used to insulate surfaces with insulating plates and seal joints between them.

Installation fire-fighting foam adhesive for expanded polystyrene is characterized by ease of use and reduced time for insulation. It is suitable for working with aerated concrete, plasterboard, glass-magnesium sheets, gypsum fiber. This material is produced in metal cylinders with a capacity of 400, 520, 750, 1000 ml. The consumption of the composition is directly related to the volume of the binder. For example, for professional glue with a volume of 1000 ml, it is 750 ml.

The brand glue is resistant to moisture and mold, it does not deteriorate over time, it is intended for outdoor and indoor use. It can be used for walls, roofs, basements, floor surfaces and foundations, applying for new and renovated buildings.

Adhesive properties allow for temporary bonding of XPS and EPS boards. It provides for fixing to cement plaster, mineral surfaces, chipboard, OSB.

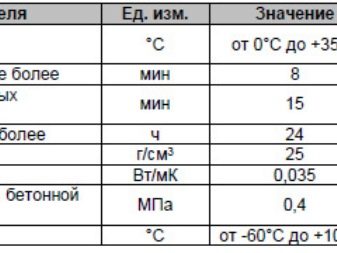

The technical characteristics of the glue-foam are as follows:

- consumption depends on the volume of the cylinder and is 10 x 12 sq. m with a volume of 0.75 liters and 2 x 4 sq. m with a volume of 0.4 l;

- material consumption from the cylinder - 85%;

- peeling off time - no more than 10 minutes;

- initial polymerization (solidification) time - 15 minutes;

- full drying time, up to 24 hours;

- the optimal level of humidity during work is 50%;

- density of the composition after final drying - 25 g / cm3;

- the level of adhesion to concrete - 0.4 MPa;

- thermal conductivity level - 0.035 W / mK;

- the optimal temperature for work is from 0 to +35 degrees;

- adhesion to expanded polystyrene - 0.09 MPa.

Storage and transportation of the cylinder is carried out exclusively in an upright position. The storage temperature can vary from +5 to + 35 degrees. The warranty period during which the adhesive foam can be stored is 1 year (in some varieties up to 18 months). During this time, the temperature regime can be reduced to -20 degrees for 1 week.

Views

Today, the company produces a line of varieties of assembly foam for the assembly gun, at the same time offering a cleaner that helps to remove the composition.

The composition in question is a professional tool, although everyone can use it.

- Professional composition for aerated concrete and masonry - glue-foam in a dark gray shadereplacing cement laying mixtures. Suitable for load-bearing walls and blocks. Has high adhesion characteristics. It features high tensile strength, suitable for fixing ceramic blocks.

- TechnoNICOL universal 500 - an adhesive material, among other bases, capable of attaching decorative panels made of solid wood, plastic and tin. Suitable for dry building technology. Has a blue tint. The weight of the bottle is 750 ml.

- TechnoNICOL Logicpir - a kind of blue shade, designed for working with glass fiber, bitumen, concrete, PIR F plates. Provides for the correction of the treated surfaces within 15 minutes. Suitable for outdoor and indoor insulation.

A separate line is dedicated to household polyurethane foams, which include 70 Professional (winter), 65 Maximum (all-season), 240 Professional (fire-resistant), 650 Master (all-season), fire-resistant 455. The products are intended for joint use, each of them has a certificate of compliance with safety standards and quality with an indication of the test report. The purifier's documentation is a certificate of state registration.

Advantages and disadvantages

Let's briefly note the advantages of the brand glue foam:

- it is immune to mold and prevents the formation of condensation;

- subject to the instructions for use, it is characterized by economy of expenditure;

- glue-foam "TechnoNICOL" has a low thermal conductivity;

- due to its composition, it practically does not react to negative environmental factors and temperature drops;

- the company's products have a democratic value, which allows work to be carried out without taking into account savings;

- it was highly appreciated by professional craftsmen in the field of construction and repair;

- in comparison with other preparations for installation with adhesive properties, it is stored longer;

- the composition is characterized by fire resistance and ease of use;

- the brand produces glue-foam in large quantities, so this product can be bought at almost any hardware store.

The only drawback of the polyurethane-based adhesive insulation material, according to buyers, is the fact that it is not suitable for mineral wool.

Instructions for use

Since each composition is different in the method of application, it is necessary to know several nuances of use indicated by the trademark, which provided a separate technology for the glue-foam.

To simplify the task, and at the same time the consumption of the composition, experts provide a detailed description of the work.

- In order not to complicate the work with foam glue, it is initially necessary to fix the starting profile-fixer on the base being processed.

- The container with the composition should be installed on a flat surface so that the valve is located at the top.

- Then it is inserted into a special assembly gun, the protective cap is removed, aligning the valve with the bridge of the tool used.

- After the balloon is inserted and fixed, it must be shaken well.

- In the process of applying the glue-foam to the base with a gun, it is necessary to ensure that the balloon is constantly in an upright position, heading up.

- In order for the application of the composition to be uniform, it is necessary to maintain the same distance between the panel and the assembly gun.

- The glue used for expanded polystyrene is usually applied along the perimeter of the plate, while retreating from the edge about 2-2.5 cm.

- The width of the foam strips should be approximately 2.5-3 cm. It is especially important that one of the applied adhesive strips runs exactly in the center of the board.

- After the adhesive foam has been applied to the base, it is necessary to give it time to expand, leaving the board for a few minutes. It is strictly forbidden to glue the thermal insulation plate immediately.

- After 5-7 minutes, the panel is glued to the base, slightly pressing in this position until the glue sets.

- After gluing the first board, others are glued to it, trying to avoid the formation of cracks.

- If, when fixing, a seam of more than 2 mm is obtained, an adjustment should be made, for which the master has no more than 5-10 minutes.

- Sometimes the cracks are sealed with scraps of foam, but it is better to do the job with high quality initially, as this can affect the formation of cold bridges.

- After the final drying of the composition, the foam in the places of protrusion should be cut off with a construction knife. If necessary, grind the seams.

What to consider when buying?

The cost of foam glue in different stores may vary. Pay attention to the release date, which is indicated on the cylinder: after its expiration, the composition will change its properties, which may affect the quality of the base insulation. A good composition worthy of a purchase has a high density. If it is too liquid, it can increase consumption, which will entail additional costs.

Choose a variety that can be used at different temperatures. Foam adhesive with frost-resistant qualities is especially highly valued. In order not to doubt the quality of the composition, ask the seller for a certificate: there is one for each type of this composition.

Reviews

Reviews of mounting glue-foame TechnoNICOL note the high quality indicators of this composition... The comments indicate that carrying out work with this material does not require certain knowledge, therefore everyone can do it. Buyers note that the use of the composition reduces the time for warming the bases, while there is no need for careful leveling of the surface. The economy of consumption of glue and the minimum secondary expansion are indicated, which allows to carry out work efficiently without overspending of the composition.

See below for a video review of TechnoNICOL glue-foam.

The comment was sent successfully.