How to glue fiberglass: the choice of glue and features of gluing technology

Currently, fiberglass is rightfully recognized as one of the most popular and demanded materials, as it is environmentally friendly and durable. He is able to transform any surface beyond recognition. In addition, such products are endowed with a lot of advantages, which did not go unnoticed by the Russian buyer.

What it is?

Fiberglass is a practical, environmentally friendly and durable finishing material of a new generation, which enjoys enviable popularity and occupies not the last place in the cladding market. Externally, fiberglass is a fairly dense and wear-resistant material, which is made on the basis of specially processed fiberglass. Such an unusual material is used for both interior and exterior decoration of buildings.

Advantages and disadvantages

Fiberglass, like all finishing materials, has weak and strong qualities.

To begin with, it is worth paying attention to the advantages that such an unusual coating can boast.

- Fiberglass is recognized as an environmentally friendly and safe coating. It does not harm the health of households, since there are no harmful and dangerous compounds in its composition.

- This material boasts heat resistance.

- Fiberglass is not afraid of dampness and moisture. In addition, it does not lose its properties under conditions of temperature jumps.

- Static electricity does not accumulate on the surface of such a finish, therefore dust does not accumulate.

- Glass fiber, like the glue for them, does not provoke allergic reactions.

- Does not emit unpleasant and pungent odors.

- It can be used for both indoor and outdoor work.

- Such material does not corrode.

- The product is fireproof.

- Such finishing materials have a long service life.

- They are not afraid of mechanical damage.

- Fiberglass is a fairly durable material.

- Such products are distinguished by vapor permeability, so they are not susceptible to the formation of fungi and mold.

- This finish does not require complex and regular maintenance.

- Fiberglass allows for repeated staining (up to 10-15 times).

- Such compositions can be safely applied to a wide variety of substrates: concrete, wood and other coatings. They can be not only walls, but also ceilings.

There are also many disadvantages of this finishing material.

- In modern stores, you can easily stumble upon cheap and low-quality fiberglass. Such a composition will be too brittle and inelastic. It is very inconvenient to work with such products, and they do not last long.

- There is a special first grade fiberglass. If there is a need to purchase it, then it should be taken into account that formaldehyde resins and phenols are present in the composition of such a product. Because of this content, first-class fiberglass can not be used for decoration of residential premises.

- Fiberglass is not able to hide many defects in the bases. For example, this material will not be able to cope with cracks and potholes, so they will have to be repaired in other ways.

- Dismantling the fiberglass can not be called simple and quick.

- For such a material in the finishing process, a large consumption is characteristic.

Material properties and field of application

A practical material like fiberglass is used in two areas:

- in the production of building materials;

- when performing finishing work.

The cost of the product itself depends on the area of application.

In the industrial field, glass fiber is used for the following types of work:

- creation of roll-type roofing materials;

- production of linoleum floor coverings;

- production of modern water panels;

- creation of materials intended for waterproofing;

- creating foam glass;

- production of glass wool slabs;

- manufacturing of special molds;

- production of special parts for drainage systems;

- manufacturing of printed circuit boards.

With regard to finishing work, in this area, fiberglass can be used for the following purposes.

- It is used in waterproofing and anti-corrosion works with pipelines. With this processing, fiberglass is combined with different types of bitumen and mastics.

- Fiberglass is often used in the interior decoration of buildings - it can be used as a base for painting, wallpaper or fixer for drywall or panels (for example, MDF) on walls and ceilings.

The fiberglass mat forms a special reinforcing layer on the surface of the base. In addition, this finishing material protects the decorative coating from cracks and other similar defects.

The seamy side of the fiberglass is outside the roll. The front half of such material is perfectly smooth, and the bottom half is fluffy and rough.

As a rule, fiberglass "cobweb" is used as a base before future finishing. It is not used as a topcoat. But it must be borne in mind that such a material is forbidden to be applied to plastered bases, since fiberglass and plaster have a different structure.

If you stick the "cobweb" on the plastered surface, then it can become covered with bubbles even when the finishing is done by an experienced craftsman.

Adhesive selection

For fiberglass it is necessary to choose a suitable adhesive. Below are the requirements that apply to such adhesive mixtures, and companies that produce similar products.

Types of mixtures

Two types of adhesive mixtures are used to apply fiberglass:

- dry;

- ready.

Finished products do not need to be prepared in advance - they are initially ready for use. However, when choosing such an adhesive solution, you need to pay attention to its shelf life. As a rule, it is indicated on the container in which the glue is located. It is worth considering that an expired product can cause a lot of inconvenience during the pasting process, for example, it starts to bubble and flake off.

If the bucket is already open, it is recommended to use the glue as soon as possible. You always need to measure the amount of adhesive with the planned production of the product. For this, knowledge of the consumption rate of the adhesive mixture, which is indicated on the package, is useful.

Dry mixes are good because they can be prepared in the volumes that are needed at the moment. Such formulations should be prepared for work, strictly following the instructions. The recipes for the preparation of these adhesive mixtures are of the same type, however, there are options with some nuances that must be followed.

Many consumers are wondering whether it is possible to install fiberglass on the popular PVA glue. According to experts, this composition can be used when working with such finishing materials.

However, it is worth considering one important point: the glued low-density canvas will let the sun's rays pass through itself, which can cause the glue to turn yellow and spoil the color of the decorative coating.

Composition requirements

A high-quality adhesive solution for fiberglass should contain a number of special components.

- plasticizer - it is this ingredient that makes the adhesive base elastic even after it has completely dried, so cracks and other damage do not appear on it;

- polyvinyl acetate is a special polymer that is known to most consumers as PVA, is a versatile adhesive that does not have toxic constituents and is suitable for many different substrates;

- fungicidal additives - these components prevent the destruction of materials applied during the repair process by bacteria;

- modified starch;

- bactericidal components.

Sometimes a special glue is included with the fiberglass. Such products can be used for finishing a wide variety of areas: a bathroom, kitchen, loggia or balcony, as well as other equally important places.

Popular manufacturers

Currently, there are a large number of large and well-known manufacturing companies on the market of building and finishing materials that produce high-quality and popular products. Below are the most popular brands offering modern consumers durable and practical adhesive mixtures for fiberglass.

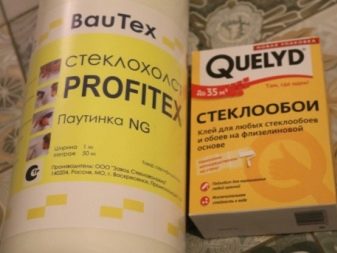

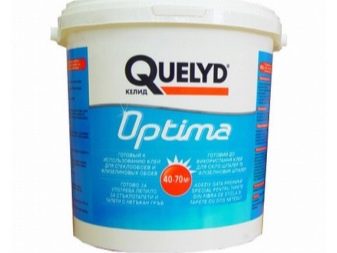

Quelyd Is a well-known brand from France that produces high-quality adhesive mixtures that form a universal joint called BluTack... This substance has many functions and allows different materials to reliably adhere.

The assortment of this large manufacturer contains different types of adhesives designed for various wallpapers, as well as sealants, cloth removers, mastics, bleaching and protective complexes and gypsum putties.

The most popular today are adhesive mixtures for glass fiber wallpaper from the line Optima, which are sold in a plastic container of 15 liters and have a low consumption per 1 m2. These types of glue can be used in damp rooms. In addition, Quelyd products contain bactericidal and fungicidal components.

The time for complete drying of such glue is 24-48 hours. Coloring of the finished base can be done after a day. Adhesive composition Quelyd it is permissible to apply both manually (using a roller) and by machine.

Famous brand Oskar manufactures high-quality adhesives (dry and ready-made) for the application of fiberglass. The products of this popular manufacturer are famous for their performance characteristics, low consumption and high adhesive properties.

Many consumers opt for glues Oskaras they are safe and harmless - there are no hazardous chemicals in their composition. Branded products meet all sanitary requirements. In addition, adhesive mixtures Oskar prevent the formation of mold and mildew under the decorative coating.

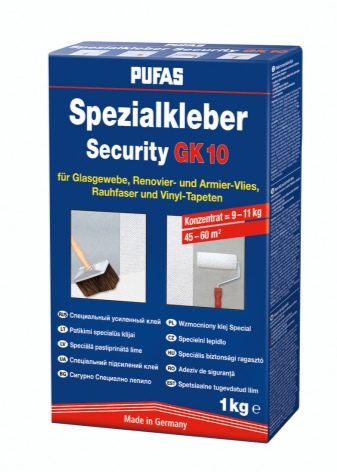

Pufas Is another popular and large brand from Europe with a representative office in Russia. The products of this manufacturer are manufactured using the latest technologies. Range Pufas very rich and varied - it is represented by various types of paints and varnishes, primers, as well as adhesives.

Ready-made glue for fiberglass from Pufas is in great demand, as it is relatively inexpensive and has excellent adhesive properties. Such products of the German brand are completely ready-to-use. As a rule, they contain antifungal components. Also adhesive mixtures for glass fiber from Pufas frost and temperature changes are not terrible.

International network Bostik offers a choice of consumers high-quality adhesive mixtures for working with fiberglass. Many of them contain binders such as PVA and starch. It is recommended to apply them on certain bases with a roller or a special brush. Such mixtures acquire full strength after 7 days.

Adhesive for fiberglass Bostik recommended to be applied on substrates in dry rooms. On such coatings, you can lay not only fiberglass, but also various types of fabrics, as well as paper and vinyl wallpaper.

Kleo - this is another well-known manufacturer from France that produces dry adhesive mixtures for the installation of fiberglass. The products of this brand are distinguished by reliability, drying in a short time, affordable cost and ease of preparation at home.

Adhesive mixtures Kleo after drying, they remain transparent. They can be divorced easily and quickly without forming hard lumps. There are no dangerous and harmful substances in their content, therefore, such compositions can be safely called absolutely safe for both people and animals. In the finished state, glue for fiberglass Kleo can be stored for up to 10 days.

Preparation and tools

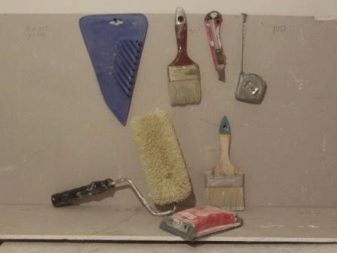

If it is decided to independently glue the fiberglass on the ceiling or walls, then you need to stock up on the following tools and materials in advance:

- rolled fiberglass;

- an adhesive mixture (it is advisable to purchase a finished product that does not need to be prepared for work on your own);

- scaffolding or stepladder;

- a paint roller on a long holder;

- different-sized brushes;

- a ditch for glue;

- a wallpaper spatula (it is advisable to purchase a plastic version);

- painting knife;

- a cutter;

- protective equipment - glasses, gloves, respirator.

If all of these units are already available, then you can start preparing the foundation.

- First of all, it is necessary to clean the walls and ceiling of the room from dirt and dust.

- Now you can open the container with the ready-made adhesive. You do not need to do this in advance, otherwise the mixture may dry out and it will be difficult to work with it.

- It is recommended to cover other objects in the room (floors, doors, window frames) with polyethylene foil.

- Then it is necessary to make markings for the dimensions of the canvas sheets on the bases - for this, a pencil or marker is usually used.

- After that, the fiberglass rolls are unrolled with the wrong side up. They need to be cut into pieces of suitable sizes, relying on the markings.

It should be borne in mind that all elements will need to be overlapped.

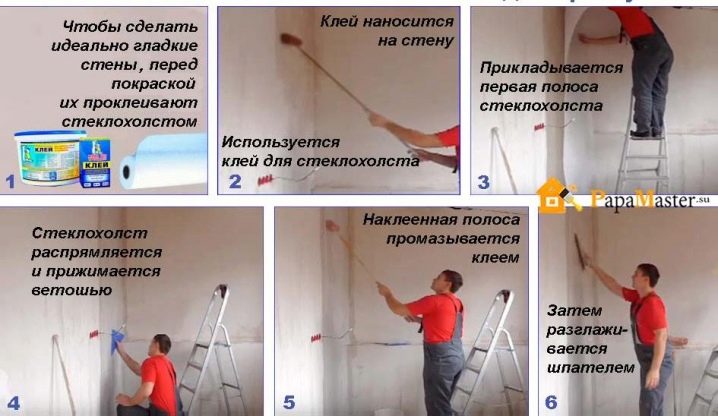

Features of gluing technology

After preparing the bases, you can proceed directly to gluing the fiberglass.

It is worth considering that there should be no drafts in the room.

- First, you need to correctly apply the glue to the wall or ceiling - a roller is suitable for this.

- In the corners and places of elevation differences, the glue should be smeared with a brush.

- Then you should install the first piece of fiberglass. To prevent ugly bubbles from appearing under it, you should walk over the surface with a special spatula for wallpaper.

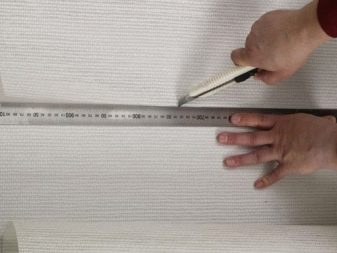

- The second piece must be glued with an overlap with an overlap of the edge by 30-40 cm.

- After that, exactly in the middle of the overflow, using a ruler, you need to make a cut with a knife.

- It is necessary to remove the cut ribbons from the side sections of the notch.

- The same should be done with pasting the corners. The first sheet needs to be folded around the corner to a width of about 40-50 cm, the next - in the opposite direction.

- An incision is made along the central part of the angle axis. After that, the remnants of the fiberglass are removed.

- The glued surfaces are covered with an additional layer of glue. Excess pieces must be removed with a spatula, which should be kept at a right angle. Remaining glue can be removed with a rag.

In this case, an additional layer of glue is necessary to avoid priming the base. Once dry, it increases the adhesion of the surface and also makes the coating more reliable and durable.

Helpful hints

Fiberglass is a common material that is used in various fields. It is glued to different substrates using special adhesive mixtures, the characteristics and composition of which are discussed above.

If you decide to independently apply fiberglass to the walls or ceiling, then you should take into account some useful recommendations from professionals in order to avoid mistakes.

- Despite its many advantages, cobweb glue also has its weaknesses.For example, if a crack appears in the place next to which the seam is located, then it will still crawl out. Most often, such defects are formed when the fiberglass is glued to the gypsum board. For this reason, experts do not recommend gluing such canvases along the seams of drywall sheets - you should step back 2-3 cm.

- When gluing, you need to pay attention to the position of the front of the canvas. Most often, it is located inside the roll. At first glance, it may seem that both sides of this material are identical, so it is recommended that you carefully study the label of the purchased product.

- Walls and ceilings are usually primed before finishing. The primer mixture will strengthen the base, as well as reduce the consumption of paintwork.

If it is necessary to apply fiberglass to the ceiling, but it is very difficult to remove the old coating with lime from it, then you can try to wet it and walk over it with a woolen rag several times.

- Always observe safety precautions during work. Before you start applying the fiberglass, you need to wear gloves, a respirator and a hat. It should also be borne in mind that sharp particles of the finishing material can get on the skin, mucous membrane or in the respiratory tract - this can cause serious irritation.

- The fiberglass must be applied on neat and even surfaces. For example, if there are height differences or any irregularities on a drywall sheet, then you first need to seal them and only then glue the finish.

- If dry glue is purchased, then it is necessary to prepare it for application, relying on the instructions. Most often it is found on the packaging. Add glue powder to the required amount of warm water, and then mix everything. The finished composition should stand for 10-15 minutes to swell. After that, the glue should be re-mixed.

If you want the glass fiber to dry out as quickly as possible, you do not need to turn on the heating devices - this can lead to deformation of the materials and their poor adhesion.

- To paint the glass fiber, you need to use a high-quality paint and varnish coating exclusively on a water basis, while the paint can be not only ordinary, but also facade.

- It is recommended to use a wide spatula to putty the fiberglass - it will be much more convenient to work with this tool.

- If necessary, fiberglass can be laid on the slopes in the room.

- According to experts, for fixing the fiberglass, as a rule, large amounts of glue are required, so it is better to buy it with a margin.

- It should be noted that it is not very convenient to work with too large sheets of fiberglass, especially when it comes to finishing the ceiling.

- If it is required that the paint on the glass fiber has a relief and rough texture, then it is worth covering the base with a leveling layer of putty.

- You need to buy both fiberglass and glue only in trusted stores so as not to run into low-quality products.

For information on how to glue a cobweb (fiberglass) on a curly plasterboard ceiling, see the next video.

The guy is doing fine.

The comment was sent successfully.