Choosing and using glue for crumb rubber

Seamless rubber crumb coatings are an environmentally friendly material for arranging roads, sites and territories for various purposes. But to achieve the durability and strength of such flooring is possible only by using a reliable adhesive base. It is worth figuring out which of the two glue options is better: bituminous or polyurethane-based.

Peculiarities

The tiles made from crushed rubber are a high-tech product intended for indoor and outdoor areas of streets and complexes. The secret of its popularity lies in the improved characteristics of the material, such as a high level of waterproofness, a safe composition, increased wear resistance, and a shock-absorbing effect that excludes injuries.

Despite the fact that some types of this material can be mounted by means of a lock connection, paving slabs, sports flooring that require laying on the ground, as a rule, are installed on a special glue for crumb rubber. Paving on an adhesive base is used when rolled rubber sheets or individual modular fragments are used.

But also an adhesive is needed to create a seamless coating as a binder.

Glue is necessary for strong fixation and uniform distribution of rubber products on any surface, therefore it must have certain physical parameters:

- good adhesion (adhesion) to the substrate: soil, concrete, wood, metal, etc .;

- a high degree of strength and resistance to mechanical deformation, climatic and weather conditions - these characteristics will increase its durability;

- since rubber coatings in most cases are used outdoors, an important quality of the adhesive base should be the immunity of the composition to the effects of microorganisms, mold, fungus and organic substances

That is why the production of glue for assembling rubber crumb products is a promising type of business, especially since the demand for such coatings is growing every year.

Species overview

Each type of glue has its own area of application and distinctive properties determined by the composition.

Polyurethane glue is a liquid transparent product, but sometimes it has a light yellow tint. Based on the degree of viscosity, its purpose also changes.

One-component composition quickly hardens in the open air due to natural moisture, although there is no hardener in its composition. Such glue is the optimal binder for the production of all kinds of rubber products: mats, carpets, roll material, paving stones and tiles.

Also, this glue base is relevant for the installation of rubber covers, but for this the surface must be primed.

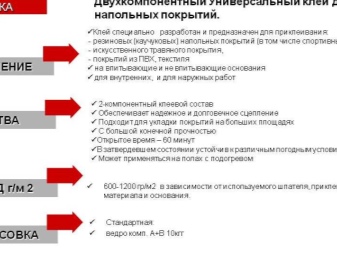

If a two-component composition of polyurethane glue is selected, then it will have to be prepared in advance - mix directly the glue and the hardener supplied with it. Only after mixing them does solidification occur, and the speed of this process depends on the taken proportions of the two components.

Advantages of polyurethane compounds used for rubber:

- ecological cleanliness, safety for humans and the environment;

- high amortization qualities;

- resistance to abrasion and external negative influences;

- good water resistance;

- the possibility of coloring rubber products by introducing pigments into the composition.

The durability of coatings created with polyurethane products is due to the absence of a solvent, and this is another plus in favor of their choice.

These types still have a slight drawback - you need to use glue after opening the package quickly, the useful properties of the material are preserved for 30 minutes.

Rubber-bitumen mastics are distinguished by special characteristics. First of all, it is a low melting point, which reduces their elasticity and strength. In addition, the bitumen included in their composition excludes rubber staining.

However, in many respects, such glue has advantages over polyurethane:

- the possibility of using mastic on inclined and vertical surfaces due to its good viscosity;

- protection of any base from moisture, which means the exclusion of the development of fungus and mold stains;

- it is preferable to lay rubber on metal surfaces using a bitumen composition with anti-corrosion properties;

- if it is necessary to make a coating on concrete, asphalt, then you should also choose a mastic, since it gives better adhesion to these materials than polyurethane mixtures.

The disadvantages of glue are vulnerability to low temperatures and high consumption due to high viscosity. Thus, different types of adhesive base should be selected based on the goals and operating conditions.

Popular manufacturers

Choosing the right composition from a wide range of these products can be difficult, but you can follow the advice of professionals.

- Pay attention to the porosity of the rubber. The larger it is, the more viscous you will need the glue.

- For absolute waterproofness, it is wiser to use a bituminous compound, however, polyurethane is suitable for sealing the joints between the slabs.

- To create coatings in natural conditions, it is better to stop your attention on an adhesive base that is resistant to frost and temperature extremes.

- For elastic sports flooring, the shock-absorbing characteristics of the glue are important - these are compositions with a coefficient of elasticity of more than 600%.

- For working with natural rubber, only special types of adhesives compatible with this material are suitable.

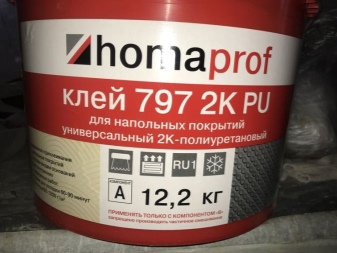

Several well-known brands offer high-quality adhesive mixtures for crumb rubber products.

- Domestic chemical company "Avenir", engaged in the development and production of polymer products, including polyurethane types of glue for rubber and other materials. The Avenir trademark is a high quality with unconditional environmental friendliness of polyurethane products, the creation of innovative compositions with increased strength and wear resistance characteristics.

- A very popular manufacturer of polyurethane binder for rubber crumb is the German company Huntsmanproducing adhesive with optimal viscosity and good compatibility with various substrates.

- Russian company "Yupak Vostok" manufactures, in addition to injury-free rubber tiles, high-quality types of one-component polyurethane adhesive compositions for easy and reliable installation of coatings.

- Gambit company - a manufacturer who is constantly improving its products, guaranteeing their high quality. The advantageous features of such a modification as "Gambit M" are well known - the glue allows obtaining seamless monolithic coatings and, moreover, is resistant to low temperatures.

Taiwan and China are also among the leading manufacturers of polymer products, including adhesives for various types of coatings.

It might not hurt to take a look at some of the certified products sourced from these countries.

How to use?

With the help of polymer glue, you can independently lay a rubber coating on a site of any size and type: wood, concrete or asphalt.

To do this, you need to prepare tools: a spatula, notched and painting, a building level, a roller, a sponge or brush for applying, a rubber hammer, chalk, a broom or a vacuum cleaner.

Any method of installing rubber plates involves a preparatory stage. The surface under the tiles is pre-cleaned and leveled, irregularities and defects are eliminated, small debris is removed with a vacuum cleaner.

The workflow algorithm looks like this:

- the base must be primed with a mixture of polyurethane glue and turpentine in equal proportions;

- separate the perimeter of the site with a rope;

- apply glue and level it with a spatula;

- it is better to lay no more than 4 tiles at a time;

- you need to start work from the center of the site, gradually moving to the edges;

- installation consists of laying out the plates with their pressing, avoiding significant gaps;

- there should be no air under the coating, the glued material must be tapped with a hammer to exclude "waves";

- at the end, a border is installed along the edges of the treated area;

- if excess adhesive remains on the rubber, it should be removed immediately.

When installing tiles, the approximate consumption of glue is about 300 g per 1 sq. m. It should also be borne in mind that air humidity during installation should not increase more than 70%, and the temperature of the air and materials should be within 10-20 degrees. A double layer of polyurethane glue will have to be applied if the installation takes place next to open natural and artificial reservoirs.

For information on polyurethane glue "Gambit M", see below.

The comment was sent successfully.