Rubber adhesive: properties and applications

Rubber glue is quite common in our life. Before buying it, you need to get acquainted with the main types of these popular formulations, as well as with their direct purpose, so that this acquisition turns out to be really useful. For high-quality bonding of rubber products, today you can find quite a lot of different materials, their special features affect the features of the application, so you should not think that any glue of this kind can be universal.

What it is

Rubber glue is a natural rubber that dissolves in a special composition. This composition has excellent elasticity after it begins to harden, which is why it is chosen for bonding different materials. Before buying such a product, you need to understand what it is, who produces it, what product is in composition and where it is used more often.

Previously, all products under the name "rubber glue" were subdivided by GOST into 2 groups according to the volume of dry residue: group A and group B. There is also a classification of products by the type of rubber used.

After numerous studies, it has been proven that the best rubber compound is made from rubber. It should contain:

- a crosslinking agent;

- additive with vulcanizing properties;

- common solvent.

This is the minimum set of components that helps to produce glue for excellent adhesion of rubber surfaces to the same rubber. But an elastic connection is more in demand for industrial purposes, therefore, the usual composition began to be supplemented with various components to increase the operational properties of such a connection.

More often, a rubber adhesive is chosen for gluing elastic parts, and this is all because the composition after it hardens, in appearance and other properties, is actually similar to rubber. But when buying this glue, you need to choose exactly one so that in terms of its composite characteristics it is similar to the parts to be joined. The product may contain not only natural rubber, but also its synthetic analogue. Ethyl acetate or other components can be used as a solvent.

The compositions of all manufacturers are different, because the qualities of adhesives of different brands can differ significantly from each other. Rubber adhesive is opaque and transparent, depending on the area of use and composition.

Peculiarities

The main feature of this glue is the ability to combine it with paper, textiles, different types of glass, wood, metal and many other surfaces. It can often be seen in furniture, footwear, and auto manufacturing. Also, this kind of product is often bought for household needs.

Disadvantages of modern rubber adhesives:

- ugly-looking seam;

- unpleasant odor;

- use only in open rooms that are quickly ventilated;

- it is difficult to apply, as it can stick to everything (and to the hands too), it can drip;

- can leave burns if applied carelessly, and in no case should it get into the eyes;

- the brush for applying the composition after application can not be washed.

The technical characteristics of different types of such glue differ significantly from each other. Even rubber glue from different manufacturers dries in different ways - instantly or over several hours.

Views

The distribution of adhesives by type is carried out according to two distinctive features: by the volume of the dry residue and by the composition of the rubber itself. According to GOST, the volume of dry residue can be from 6-8% to 8-12%. Glue, if it contains from 6 to 8% of the dry residue, is known as grade A (more elastic composition), and when the indicator is from 8 to 12%, then it is glue released under the brand B.

The most used classification is according to the characteristics of the rubber contained in it.

Such glue may well not be suitable for certain areas of industry, therefore, separate compositions were created, the basis of which are synthetic components. Real rubber glue cannot resist the aggressive action of all kinds of environments and high temperature conditions on it.

The most common types of rubber products are:

- Natural rubber compounds. This substance contains sulfur. This glue is chosen for gluing parts made of cardboard, leather or fabric. Suitable for carpet.

- Chloroprene composition. For the implementation of vulcanization, divalent metal oxides are included in it. The composition is very good in terms of connecting qualities, and therefore it is chosen for gluing metal and other elements.

- Adhesive with the inclusion of nitrile butadiene rubber. Sulfur also acts as a vulcanizing element here, but only with the addition of thiuram. This adhesive is water resistant and is selected for a variety of popular materials.

- Silicone glue. Its hardening occurs only under the influence of tetrabutoxylane. It is rarely used, as it can only glue homogeneous rubber.

- Styrene butadiene adhesive. It has a weak gluing ability and therefore is bought only for production, for example, for the production of scotch tape. Other artificial rubbers can also be the basis of this kind of glue, but their use is limited.

Adhesives for rubber are divided according to their intended purpose: for industrial and home use (for gluing various coatings at home). Industrial glue is used in manufacturing, it is produced in huge volumes, and it is applied to coatings using special tools.

Such compositions are glue 88, 88 N and 88 CA. They are found in the construction industry - for the installation of various finishing surfaces, in the automotive industry - for gluing rubber products, in the production of furniture and any footwear. This product is suitable for gluing rubber and gluing it to metals, paper, wood.

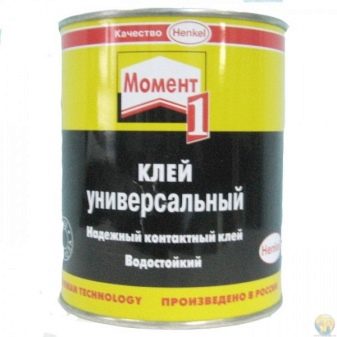

Fast drying universal adhesive "Moment-1". It is better to choose it for gluing rubber, wood, metals, leather and felt, plastic and glass, as well as ceramics. This high-strength composition is very toxic and quite flammable, therefore it can be used only in air or in a room that is ventilated, while keeping the composition away from open flame.

It is applied in the thinnest layer on two completely dry elements, which are first of all cleaned and degreased, then they are kept for about 15-20 minutes until completely dry. After that, both surfaces are strongly pressed against each other for only 10-15 seconds.

You can also often find such a type of rubber glue as liquid rubber - a transparent polyurethane glue-paste for repair work, protecting surfaces and their high-quality waterproofing. This composition is distinguished by its resistance to wear and tear, flexibility, it completely fills the existing gaps, and is not afraid of temperature changes.

It is also worth mentioning about the rubber adhesive sealant - this is a high-strength adhesive that is needed for high-quality repair of seals in doors and windows. It hardens very quickly, adheres perfectly porous and non-porous materials.

Famous brands and reviews

- Glue 88 N. This composition adheres rubber materials to metals well and for a long time. When dry, it is slightly diluted with benzene to the state of ordinary sour cream, while the glue itself should not drip from the brush or be pulled out with a thread.They lubricate rubber (or other material) and dry for about 3-5 minutes, after which the second layer is applied to the rubber and the first layer to the metal. Two elements need to be dried for 5-6 minutes. Then both parts are superimposed on one another - this is how they are dried for about a day, placing them under a good press.

- Rubber glue is 5 or 7% rubber dissolved in gasoline without impurities. These days it is often replaced by synthetic rubber compounds. The most popular type of such adhesives – 88 CA. It is a colloidal solution of rubber and resin, which is mixed with nefras and ethyl acetate. Selected for bonding rubber and concrete surfaces as well as glass and wood. This composition is well suited for laying flooring on cement or wood, bonding foam and foam together. You can also use this glue for working with fabrics and leather, for a quick repair of any pair of shoes. Glue 88 CA is waterproof, it does not turn into a poisonous compound when exposed to air, it can withstand temperatures from -500 to +700 degrees.

- Another composition - well-known to everyone glue 4508. It is not afraid of water, gives elasticity to the seams, and has high stickiness. This composition can be found in the manufacture of textiles, the production of various rubber products, special protection suits, rubberized fabrics. High elasticity allows it to become popular when gluing PVC boats, leather haberdashery, suits for fishermen.

- Excellent reviews have a composition Loctitewhich is very fast. Using it, you can repair a boat in difficult conditions in 5-7 minutes. This composition also has a minus - instant gluing, which will differ in uneven connection over the entire area.

- Glue "Radical". Many fishermen advise that you always have this elastic adhesive with you. It can withstand a fairly high pressure and significant stress. "Radical" is not afraid of negative temperatures, it works excellently in both fresh and salt water. This glue is considered indispensable for the quick repair of rubber boats.

- Gummy glue. It is a natural rubber compound. It is waterproof and therefore can be used for gluing various rubber and inflatable products: boats, car and bicycle cameras, leather haberdashery.

Selection and application

To correctly acquire the best adhesive for rubber, it is worth answering the whole question: where exactly it will be used.

Before purchasing the composition, you should also answer other questions that will help to identify certain features of the properties of the selected glue:

- Will the glued product be heated or cooled? Various formulations are able to withstand different temperatures. If you plan to use glue in difficult conditions, you need to make sure that it is a composition that is not afraid of these conditions.

- Can the product be subject to frequent shocks, any vibration, or severe deformation during operation? Almost any professional rubber adhesive is resistant to mechanical stress. But there are varieties that have increased resistance to tearing forces. They can be used for gluing door seals or for vacuum rubber.

- What seams should be applied to the product to be bonded? For thin types of seams, liquid adhesives are selected, for thick ones - with a thicker texture.

- What kind of elements do you need to glue? To choose the right glue, you should get acquainted with the scope of its use. For example, if it is necessary to glue the floor coverings with rubber glue.

- Will the composition come into contact with food? Some types of adhesives are highly toxic. Therefore, to restore bowls and plates, you need to buy the safest composition.

All characteristics of the glue can be found in its instructions for use. It is advisable to ask the seller for advice on the availability of those adhesives that he sells.

Before gluing, the surface is degreased and cleaned of dirt.To do this, you can use acetone, which will contribute not only to good cleansing, but also make the rubber structure softer. Various contaminants can contribute to a decrease in the adhesion itself and reduce the durability of the composition, and then the parts will need to be glued again after some time.

Bonding is best done over several stages. A layer of primer will come in handy here, which will help the glue to show the result qualitatively.

To improve the quality of adhesion, it is better to take a technical hair dryer - when using it, the connection heats up well (up to 60 degrees). But you cannot bring the glue for heating to an open flame.

Advice

In order to get an excellent result when using adhesives for rubber, it is extremely important to observe a special technology when gluing - it is usually indicated on the jar of glue itself or its tube.

It is imperative, first of all, to make high-quality surface preparation before the pasting process. Rubber can be contaminated with residues of all kinds of materials, dust or oils that were in direct contact with it. You can remove these types of contaminants by using special cleaning compounds or a special type of solvents. If the rubber surface was mechanically cleaned with abrasive agents before gluing, then you need to remove all residues of the resulting dust with cleaners or dissolve all the dirt accumulated on the surface.

The glue application technology requires the correct execution of the instructions in order to achieve the best result. Therefore, it is worth knowing that there are two types of gluing: hot and cold.

In the first method, gluing is carried out at a temperature of 70 to 160 degrees, and the duration of the process can take 5-10 minutes. The second option requires gluing to be carried out at normal room temperature, but the curing time will increase up to 2-3 tens of hours.

It is necessary to prepare the surfaces to be glued well in order to obtain a strong connection in the end. Before degreasing the rubber during gluing, you need to treat it with fine sandpaper - this will increase the contact area.

For high-quality degreasing, you can take some kind of solvent that evaporates easily, for example, ordinary acetone or even gasoline.

A number of compounds can thicken and then they can be diluted. There is no universal type of diluent in nature. And although all rubbers can easily dissolve in hydrocarbon components, for each of them you need to choose a different type of diluent.

For nitrile butadiene rubber, nepras or ethyl acetate are chosen. Before diluting 88 glue, you need to thoroughly heat it in a steam bath to 40-45 degrees. This preparation will help prevent lumps from forming.

For information on how to increase the effectiveness of the glue, see the next video.

The comment was sent successfully.