Using Plitonit B glue

The construction market offers a huge range of products for laying ceramic tiles. Plitonit B glue is in great demand among buyers, which is used not only indoors, but also outside.

Peculiarities

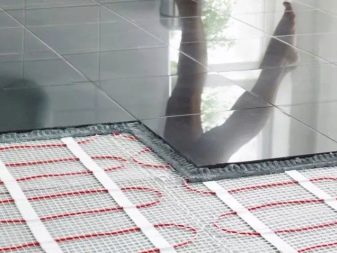

Plitonit is a Russian-German joint venture for the production of construction chemicals for professional and domestic use. Tile adhesive Plitonit B is one of the names of a huge range of products of this brand. It is designed for indoor installation of ceramics and porcelain stoneware tiles. The base for gluing can be made of various building materials: concrete, reinforced concrete, gypsum plaster, brick, tongue-and-groove slabs. This type of glue is also used for tiling floors that are equipped with a heating system.

Due to the plasticity of the composition, the facing material does not slide off vertical surfaces.

The composition of the mortar includes cement binders and adhesive components, as well as fillers with a maximum grouping of grains up to 0.63 mm and modifying additives that give it increased adhesive qualities.

Advantages and disadvantages

The use of Plitonit B glue has its advantages.

- Reasonable product price.

- High elasticity of the material.

- Glue preparation for work does not require any special skills. It mixes easily with liquid even without a mixer.

- Has excellent adhesion to vertical surfaces.

- Moisture and frost resistance of the product. Suitable for outdoor use, as well as in rooms with high humidity.

- High performance.

- Installation takes a minimum amount of time.

- Wide area of use.

There are basically no drawbacks when using this adhesive solution, but with incorrect installation work, the facing materials may lag behind the surface. The material is produced in bags of 5 and 25 kg, it is not possible to purchase a mixture in a smaller volume.

Specifications

Main parameters:

- the largest grain volume - 0.63 mm;

- appearance - gray, free-flowing homogeneous mixture;

- sliding of the tile material from the vertical surface - 0.5 mm;

- open time of work - 15 minutes;

- the time for adjusting the tile material is 15-20 minutes;

- the pot life of the finished mixture is no more than 4 hours;

- maximum thickness of the adhesive layer - no more than 10 mm;

- temperature regime for installation work - from +5 to +30 degrees;

- trowelling works - after 24 hours;

- the temperature of the glue seam during operation - up to +60 degrees;

- frost resistance - F35;

- compressive strength - M50;

- adhesion strength of a tile to a concrete surface: ceramics - 0.6 MPa, porcelain stoneware - 0.5 MPa;

- shelf life - 12 months.

Consumption calculation

The instructions on the packaging indicate the approximate consumption of tile adhesive on any surface, but the amount of material required can be calculated independently. Adhesive consumption depends on many factors.

- Tile size: if it is large, then the glue consumption will be large.

- Tile material. Ordinary tiles have a porous surface that absorbs glue better. On the other hand, porcelain stoneware tiles absorb less adhesive mortar.

- Smoothness of the surface: a smooth one will need less glue than a corrugated one.

- The quality of the prepared substrate.

- Specialist skills.

For tiles measuring 30x30 cm, the average consumption of glue will be approximately 5 kg per 1 m2 with a joint thickness of 2-3 mm. Accordingly, for cladding 10 sq. m of area will need 50 kg of adhesive. For a tile of a smaller size, for example, 10x10 cm, the average consumption will be 1.7 kg / m2. A tile with a side of 25 cm will require approximately 3.4 kg / m2.

Stages of work

In order for the repair to be carried out efficiently, it is necessary to perform sequential steps when laying the tiles.

Preparation

It is necessary to apply Plitonit B glue on a solid, even, solid base that is not subject to deformation. It is recommended to thoroughly clean the working surface of various types of contamination: debris, dust, dirt, old coating (glue, paint, wallpaper, etc.), grease. Crevices and cracks are sealed with putty, and after that the working surface is treated with a primer solution.

Plasterboard materials also need to be treated with a primer, it is better to use a mixture of the Plitonit brand. This is necessary to protect the surface from the appearance of fungi and mold.

If the coating has a loose structure, then it must be primed in 2 layers. The floors are also treated with a special compound to prevent the appearance of mold under the tiles, especially for bathrooms.

Preparation of the mixture

Before you start preparing a tile mixture, you must take into account certain recommendations.

- All components used must be at room temperature.

- For mixing, tools and containers are used that are completely free of contamination. If they have already been used to prepare the mixture, then the remains of the solution must be eliminated. They can affect the properties and qualities of the freshly prepared formulation.

- For the convenience of pouring the mixture into the container, you can use a trowel.

- Only pure water is used for mixing, preferably drinking water. The technical liquid may contain alkalis and acids, which will negatively affect the quality of the finished solution.

For 1 kg of dry mixture, 0.24 liters of water will be needed, respectively, for 25 kg of adhesive, 6 liters should be used. Water is poured into a suitable container and the dry mixture is added. Mixing takes about 3 minutes, you can use a mixer or drill with a special attachment, the main thing is to get a homogeneous consistency without lumps. The readiness of the mixture is determined in such a way that when applied to a vertical surface, it does not drain.

The finished mixture is set aside for 5 minutes, after which it is mixed again. In some cases, it is possible to add water, but it is not recommended to exceed the indicated values in the instructions.

It is necessary to apply the ready-made solution within 4 hours, but if the room temperature is high, then the time of use is significantly reduced.

Subtleties of application

- Plitonit B is applied with a smooth trowel in a thin, even layer. The adhesive mortar coating should be given a comb structure for better adhesion to the tiles.

- If a dried crust forms on the surface of the applied solution, the layer is removed and replaced with a new one. The tile is placed on the glue and pressed into the mixture with gentle turning movements. The position of the facing material can be corrected within 20 minutes. When installing tiles, it is recommended to use a laser level.

- At the end of the work, excess adhesive solution is removed from the tile joints. Peeling is done with a knife until the mixture is frozen. The front side of the tile is cleaned from dirt with a rag or sponge soaked in water or a special solvent.

- When facing floors with a heating system, as well as laying tile materials of large sizes, in order to avoid the appearance of voids under the finished coating and to increase adhesion, experts recommend applying glue using a combined method. The composition is applied both to the prepared base and to the back of the tile.It is necessary to apply the adhesive to the tiles with a notched trowel, and then level the layer with a smooth one.

The consumption of Plitonit B glue in the combined method will increase by about 1.3 kg / m2 with an applied layer thickness of 1 millimeter.

You can often hear the opinion that you can walk on the tiles on the floor without waiting for the glue to dry completely. It is strictly forbidden to do this, because:

- if the adhesive solution had time to dry out, but did not gain maximum strength, then there is a great risk of shearing the masonry;

- damage to the tile material can occur, especially in areas where voids have formed due to insufficient application of mortar.

Recommendations

And a few more tips from experts.

- It is recommended to walk on the tiled floor and grout the joints only after the glue has dried (after about 24 hours). Of course, the solution dries longer, and it will gain full strength only after a few days, so it is not recommended to exert heavy physical influence on the newly laid tile (move furniture along it, for example). Otherwise, after 1.5-2 years, repairs will have to be carried out again.

- It is not recommended to connect the underfloor heating system earlier than after 7 days.

- Additional heating of the room will speed up the drying process of the adhesive mixture.

- Before starting the installation of the tile, it does not need to be soaked, it is enough to clean the back of the material from dust and debris.

- In the process of laying the tiles, the adhesive solution must be stirred periodically so that a film crust does not form.

- When performing work, use protective equipment (gloves, glasses) so that the solution does not get on the skin and eyes. The likelihood of splashing and eye contact is increased when using a mixer to stir the mixture.

- Store the Plitonit B adhesive in a closed, dry room, so that the environmental conditions ensure the integrity of the packaging and protection from moisture.

- Keep out of the reach of children!

- Experts recommend preparing the adhesive solution in small portions so that it can be applied within 4 hours. The closer to the end of the pot life of the finished mixture, the lower its adhesion to the product.

Plitonit B glue has received a lot of positive feedback from professional builders and newbies. Buyers note the ease of use, affordable price, impeccable performance. Another advantage of the composition is its excellent compatibility with surfaces made of a wide variety of materials. The glue is versatile, which is an important factor when choosing materials for repair.

If we compare it with similar compositions from well-known brands, then Plitonit B is not only not inferior to them, but also surpasses them in many ways.

The main thing is to follow the recommendations of specialists when working with this type of adhesive solution, adhere to the instructions, ensure optimal temperature and humidity conditions, and then the result will not disappoint you.

For details on the use of Plitonit B glue, see below.

The comment was sent successfully.