Litokol glue: technical characteristics and scope of use

In order to make quality repairs, it is necessary to take a responsible approach to the choice of not only finishing materials, but also related products. When tiling or mosaic surfaces, it is essential to use a high quality adhesive. The glue of the Italian brand Litokol is very popular with buyers in more than 90 countries around the world, due to its high technical characteristics and an extensive scope of use.

Properties

The Italian company Litokol specializes in the development and production of adhesives for mosaics, tiles, porcelain stoneware, and natural stone tiles. In production, only the highest quality raw materials are used, which makes it possible to obtain glue with excellent technical characteristics. Under the Litokol brand there are several modifications of adhesive mixtures, each of which has its own qualities.

Speaking about the general properties of materials, the following points can be highlighted.

- Health safety. In the manufacture of Litokol adhesive mixtures, no harmful components are used, therefore the finished product is absolutely environmentally friendly.

- High level of adhesion to almost all types of substrates. The adhesive composition allows tiling even complex substrates such as wood and plastic surfaces.

- Excellent resistance to moisture and water. The Litokol range of materials also includes a separate type of mixture for tiling swimming pools.

- Resistant to high and low temperatures, as well as to its sharp drops.

- The mixture has good elasticity characteristics.

Varieties

A wide variety of adhesive mixtures are produced under the Litokol brand.

All formulations can be divided into three main groups:

- cement-based mixtures;

- acrylic dispersion mixtures;

- epoxy reactive composition.

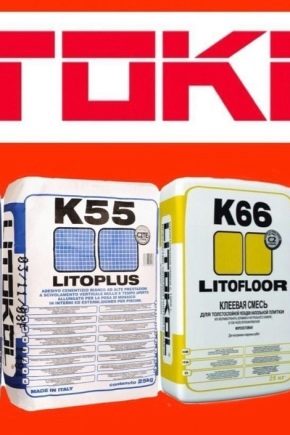

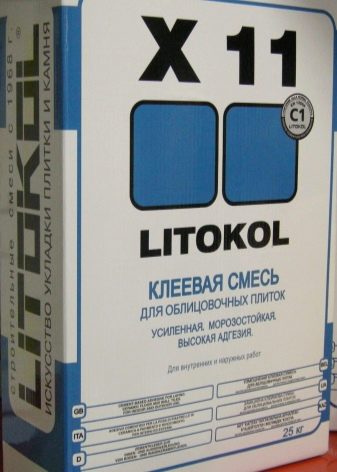

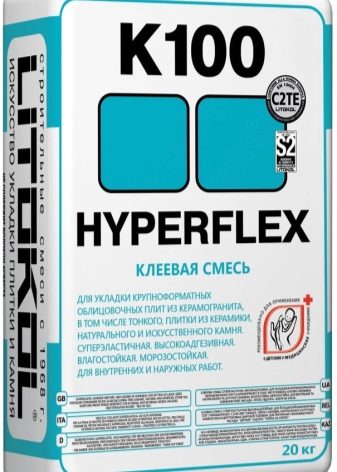

Each group of adhesives has its own characteristics. Cement compositions have the widest range. Compounds such as Litokol X11, Hyperflex K100, Hyperflex K100 white and Litoflex K81 are especially popular due to their versatility in application. Such adhesive mixtures are characterized by fast hardening and no shrinkage. Cement-based materials have a low cost compared to other modifications of the Litokol product.

It is worth noting that the low price does not affect the quality of the glue in any way: the technical characteristics of cement mixtures are not lower than those of other compositions.

The material can be used both indoors and outdoors, withstands sudden temperature changes and the effects of atmospheric factors. Cement mixtures are produced in dry form.

Dispersion mixtures are represented by two products: Litoacril Fix and Litoacril Plus. The formulations are available in the form of a white paste, ready for application. The material has a fairly wide range of operating temperatures, which ranges from -30 to +90 degrees. The mixture is not afraid of direct contact with water and does not absorb it, which makes it possible to use this glue in rooms with high levels of humidity.

Epoxy resin tile adhesive is mainly used for tiling difficult substrates. The composition is distinguished by its high strength and resistance to mechanical stress, therefore it is ideal for laying tiles in places with high traffic.

Selection Tips

Thanks to the wide range of Litokol adhesive mixtures, you can choose the right composition for any task. When choosing, consider the following factors:

- place of finishing work: inside or outside the premises;

- base type: horizontal or vertical surface;

- the materials from which the tiling and base are made.

When buying material, you must carefully study the technical characteristics of the composition indicated on the packaging, which will allow you to determine its purpose and properties. You can also pre-familiarize yourself with reviews for various modifications of Litokol glue.

Interior decoration

For indoor work, you can use both universal adhesives Litokol, and special-purpose compounds. As a rule, special modifications of glue for interior work are made from the most environmentally friendly raw materials. If cement-based compositions are used, then it is desirable that when preparing the solution, the amount of dust emitted is minimal. The dust-free materials category includes the mixtures Litogres K44 ECO and Litoflex K80 eco.

For outdoor work

For finishing the facades of buildings, sidewalks and porches, it is necessary to choose compositions that have good resistance to weathering and temperature extremes.

It is also worth paying attention to the mode of operational parameters of the mixture. Outdoor formulations must withstand high temperatures and be frost resistant. For example, these are mixtures such as Litokol K17, Litoelastic, Litoplus K55 and Litofloor K66.

Difficult foundations

Complex substrates include surfaces that will be subjected to significant mechanical stress during operation, as well as some materials: wood, iron, plastic, asphalt, old finishing layer, warm floor. The two-component composition Litokol Litoelastic is well suited for this purpose, due to its versatility.

This mixture has high adhesion to any substrates, has no shrinkage and is highly resistant to the negative influence of external factors. The glue is not afraid of water, and it is also resistant to vibrations, therefore it can be used in elevators or on staircases. Adhesive can be used to finish the underfloor heating system. Litoflex K81.

Also a dispersion blend works well with some difficult substrates. Litoacril Plus... With this composition, you can lay tiles on surfaces that are subject to deformation, wood panels, as well as on old finishing materials (for example, on tiles or paintwork).

Wet rooms

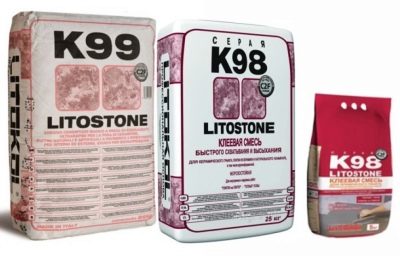

In rooms with a high level of humidity, it is necessary to use only those compounds that are water-repellent. Among the various Litokol adhesives, you can find many suitable options for decorating bathrooms and swimming pools. For example, mixtures Superflex K77, Litostone K98, Litoflex K81, Litoplus K55, as well as dispersion compositions.

Various materials

Litokol adhesive mixtures are widely used for tiling surfaces. However, some modifications of the glue allow you to work with other materials. Litokol acrylic-based compounds are widely used for fixing various sound and heat insulating materials.

Betonkol K7 is used for the formation of walls and partitions from bricks, aerated concrete, foam blocks and other materials. Also, this composition can be used to level surfaces. Some Litokol adhesive mixtures can be used for laying marble and other natural stone, including large format.

Application features

Each type of Litokol adhesive mixtures can have its own application characteristics. For this reason, before starting work, it is recommended that you familiarize yourself with the instructions that are indicated on the packaging of the material.

Surface preparation

To work with any composition, it is necessary to prepare the surface. It should be flat and clean.If the tiles are to be laid on the floor, it is necessary to wait until the cement-sand screed is completely dry (about 28 days from the moment of formation). The presence of small irregularities on the surface (no more than 0.3 cm) is allowed.

After cleaning and degreasing the surface, it is recommended to treat the base with a primer water-repellent compound. The primer must be completely dry before applying the adhesive mixture.

Application

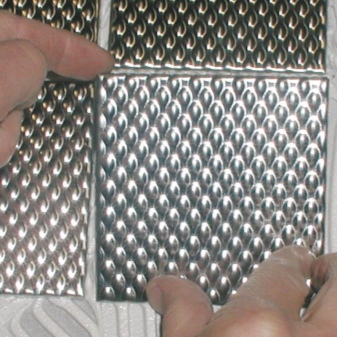

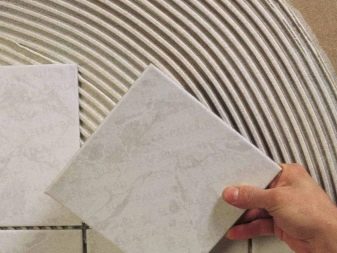

The adhesive composition is not applied to the entire area of the treated surface at once, but only to a small part of it. The layer of glue should be uniform, for this, the mixture is distributed with a metal spatula, after which it is exposed to it with a notched trowel. The tile material is laid on the treated surface and pressed down well.

After laying the tiles within one day, the adhesive composition must be reliably protected from direct contact with water. In the next week, the surface must be protected from freezing temperatures and direct sunlight.

Tips & Tricks

Certain types of substrates and adhesives can be difficult to handle. There are a few things to keep in mind when buying material and using it.

- It is not recommended to use cement compositions for gypsum surfaces, since these materials do not interact well with each other. An alternative solution might be to prevent direct contact between them. To do this, before applying the glue, gypsum bases are subject to mandatory priming.

- Before laying glass mosaics on the surface of the pool or fountains, the base must be treated with a mixture of cement and sand in order to perfect leveling.

- It is always necessary to take into account the curing speed of the used Litokol glue, since after the formation of a film on the applied composition, it will be possible to glue the tiles to this area only after applying a new layer. It is worth remembering that drying time may vary depending on temperature and humidity conditions. For example, in direct sunlight and under the influence of dry wind, the glue hardening process will be faster.

- When working with Litokol adhesive mixtures, tiles do not need to be soaked in water.

- If it is necessary to tile surfaces that will be subjected to high mechanical stress, it is recommended to apply the adhesive mixture both to the base and to the back of the tile.

For information on how to properly apply glue to tiles, see the video below.

Kitchen tiles have been in use since the 90s. We decided to make a new renovation and choose modern tiles. We selected high-quality glue, I was glad that glue can be found in any hardware store. As a result, I was satisfied with the quality, I can safely recommend it.

The comment was sent successfully.