How to use a hot glue gun?

The hot glue gun is a tool that has become popular due to its simple design, while its adhesion strength is top notch and does not take long. This device is called folk without reservations, since it is found in almost every home.

What is a glue gun and where is it used?

The main advantage of this device is its simplicity and ease of use, and consumables cost a penny. And the device itself is not expensive, but it opens up a lot of possibilities. The thermal gun is in the arsenal of builders, it helps to fix engineering communications, seals, glues, fills the seams. It is used by needlewomen, florists, designers, making it possible to glue various accessories, make all kinds of designs.

Radio amateurs actively use glue guns when repairing microcircuits and wiring. Even artists have seen decorative value in the polyurethane melt, creating drawings from the glue mass. In household use, this thing is irreplaceable, with the help of such a pistol, even broken dishes can be restored.

The glue gun connects various parts almost immediately, since the polymer, heated to a certain temperature, solidifies in just a few minutes; the gluing is durable and does not make you wait for setting, unlike other types of glue. The hot gun is used for working with wood, plastic, leather, glass, metal, paper, ceramics, fabric, PVC, rubber, foam.

It is not recommended to use it with concrete or plaster, although this is a controversial issue, tests show that a hook made of metal glued to the wall can support a relatively large weight. It is rarely used in working with polyethylene, since at high temperatures it melts and deforms. Polymer glue is not used in places with a temperature equal to the melting point of the glue itself. And most importantly, if it is necessary to remove glue from almost all surfaces, this can be easily done.

The cured polymer is elastic and moisture resistant. Polymer glue is harmless.

It is necessary to work with such a tool carefully, adhering to safety rules, since burns are possible, the melting temperature of the glue reaches 200 degrees.

Hot glue gun working principle

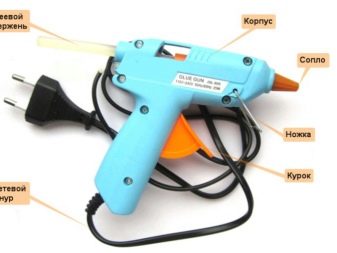

A thermal gun is a hand-held tool, very similar to the type of weapon. It also needs to be charged, but not with live ammunition, but with cylindrical rods made of polyurethane glue of various diameters. The gun itself is made of heat-resistant plastic, which makes it lightweight. Powered by a 200 W socket, some models are equipped with a built-in rechargeable battery. On the back of the device there is a hole into which a glue stick is inserted, the diameter of the tube depends on the model.

Spare glue enters the bushing of the push mechanism, falling into a special pipe - rubber receptacle, and from it the edge of the rod rests against the heating chamber, in which the polyurethane melts, turning into an adhesive mass. It will take no more than 5 minutes to heat up the tool after switching on. On the handle of the unit, like a real pistol, there is a trigger.With its help, the piston is triggered, creating pressure in the heating chamber, which allows the already liquid glue to be pushed out through the nozzle onto the surface of the material to be glued.

The performance of the tool directly depends on the heat chamber, which is located in the barrel of the thermal gun. The size of the chamber and the power of the heating element affect the amount of melted adhesive mass and the rate of polymer melting.

When choosing a tool, be sure to pay attention to the feed mechanism, as this is a capricious design and often breaks down.

The hot gun nozzle shapes the glue and dispenses the flow of molten mass. It is made of metal. Some brands produce tools with different attachments that differ in length and shape.

It is important not to forget to clean the adhesive from the nozzle after each use of the unit.

The latest models of glue guns are also equipped with a backlight, which is important when working with it in a room with poor visibility or even in the dark.

There is a viewing window on the body of the glue gun, an important option for checking the remaining stick. Almost all devices are equipped with a folding stand to support the tool with the nozzle down, since it is not recommended to put the gun on its side, the body can overheat.

The power of the gun is a measure of the rate at which the glue stick melts. The higher the power, the faster the adhesive melts. Professional hot guns from three hundred watts, and amateur up to 150 watts. Some devices are equipped with a power regulator. Heating indicator - a light on the gun body will show when you can start working, and the glue melts to the desired temperature. The melt temperature of the adhesive is also of great importance, as some materials cannot withstand high temperatures.

There are tools for a specific material, but it is more profitable to purchase a unit with a controlled temperature. Any rod melts at 105 degrees, and higher temperatures simply speed up this process.

Replacement hot gun rods vary in diameter, color and operating temperature. Stickers can be of different lengths (from 4 to 20 cm). The rod diameter is selected according to the configuration of your particular gun.

Colored rods are for masking seams or for decoration. Transparent glue is universal, black is intended for sealing, yellow is used for glass. Even glitter rods have appeared on the market, which opens up more possibilities for decorators.

Preparation for work with a thermal gun

The principle of operation of hot melt guns is the same and you need to know step by step how to use it. This is an electric tool, so safety precautions are required. Before each use, you need to inspect the device, there should be no damage to the gun body. Any unnoticed, even the smallest crack, can lead to problems. Next, you should inspect the nozzle, it should not be clogged.

The rod is inserted into the connector until it stops, a new sticker is added only after the first is completely used up.

Straighten the cord before plugging it into a power outlet. Often the length of the cord does not allow you to freely use the tool, in which case you need to use an extension cord. There is a switch on the gun body that allows you to adjust the heating temperature of the glue. The heat chamber does not melt the glue after a while, since it needs to warm up. The indicator will show the start of work with the device.

Algorithm for using a hot gun

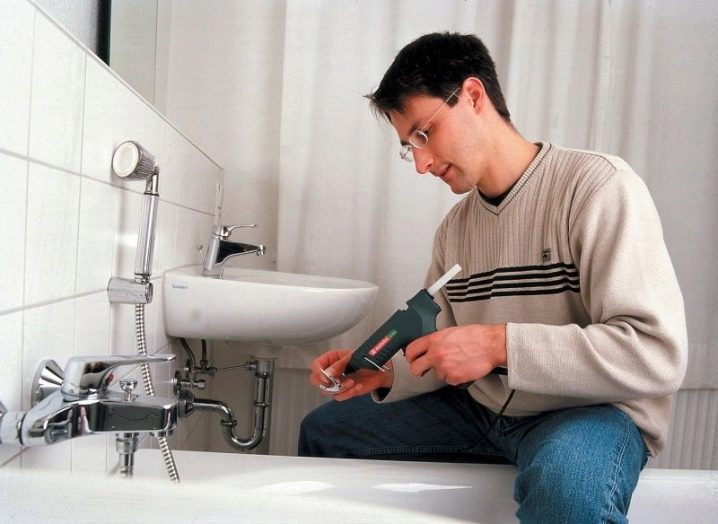

When the inspection is over, proceed to work with the device. If you use the tool correctly, an excellent result will be guaranteed.

The polymer heats up over time, so do not rush to pull the trigger immediately after turning it on. While the device is warming up, the material is being prepared for work. The surface of the material must be clean and free from grease.The required volume of polymer is adjusted by pulling the trigger. You only need to squeeze out the amount of polymer you need.

The polymer in the molten state keeps the temperature for a few more seconds. During this time, it must be applied to the material and pressed against each other. You need to melt slowly. A large amount of polymer will take longer to bond.

During a break in work, the device must be placed on a stand so that hot glue does not flow into the gun.

Do not exceed the time of using the included instrumentspecified in the instructions for it. The professional thermo gun can be used for 2 hours, the creative guns must be turned off after 20 minutes. During a break in work, a thin cobweb may form, which is not difficult to remove in a solid state. After finishing work, you should wipe the tip from the remaining glue.

Advantages and disadvantages of a thermal gun

The benefits are numerous. This hot gun provides instant bonding. Adhesion strength is high, it adheres well the same materials to each other, and combinations of materials to each other. The appearance of the glued surface is excellent in appearance. There is a large palette of glue sticks, you can match the color to any surface. This tool is irreplaceable for fastening work, where it is necessary to do without mechanical stress. It is believed to be environmentally friendly and absolutely safe.

There are few disadvantages of the thermo gun. It does not adhere well to polyurethane with concrete, plaster and cement. And you cannot use this device in a place where a part glued with such glue will be subjected to further heating. For needlework, such a unit is ideal. You can use it to make unique things.

For more information on glue cartridges, see the next video.

The comment was sent successfully.